More Washing Machines, Fewer Robot Housekeepers

Robotics is NOT at a crossroads. Crossroads imply clear choices, a moment of decision, and a path forward. But robotics still lacks that clarity. Instead, robotics is wandering without a map.

What the field needs is not more capital or bigger promises, but better frameworks for evaluating ideas and guiding innovation. If investors and founders can measure opportunities against these structures, robotics can finally move from flashy demonstrations to truly transformative technologies.

The problem isn’t a shortage of talent. Robotics attracts some of the brightest engineers and designers in the world. The problem is an industry that operates without the tools necessary to evaluate ideas. Without structure, investors reward novelty, and founders chase the “next big thing,” building prototypes optimized for viral demos instead of real-world impact.

If the robotics industry is going to fulfill its potential, we need structures and frameworks to measure our ideas against, so people can realize truly innovative technologies.

The Fog of Robotics

The first problem is definitional: what exactly is a robot?

If forced to define it, most people would consider it a system of electronics, mechanics, and software interacting with the physical world. By that standard, a dishwasher is a robot. However, when most people picture robotics, they think of the bipedal robots or robot dogs they see on YouTube.

This disconnect between the definition and the image fuels hype. The term was coined in the 1920s and from that point on futurists promised robots that would change the world. There are videos from the 1960s promising robot housekeepers just a decade away! In 2024, the industry is making the same promotional videos. The AI is smarter and the format more stylish, but the promises are just as far from reality.

The reality is robotics doesn’t make a business successful. Successfully businesses automate. Automation has been quietly transforming the world for centuries. The washing machine, for example, created immense social and economic value by freeing up hours of human labor. The goal of transformative business and societal success is automation; robotics is just a tool to get there.

How do we tackle an automation challenge?

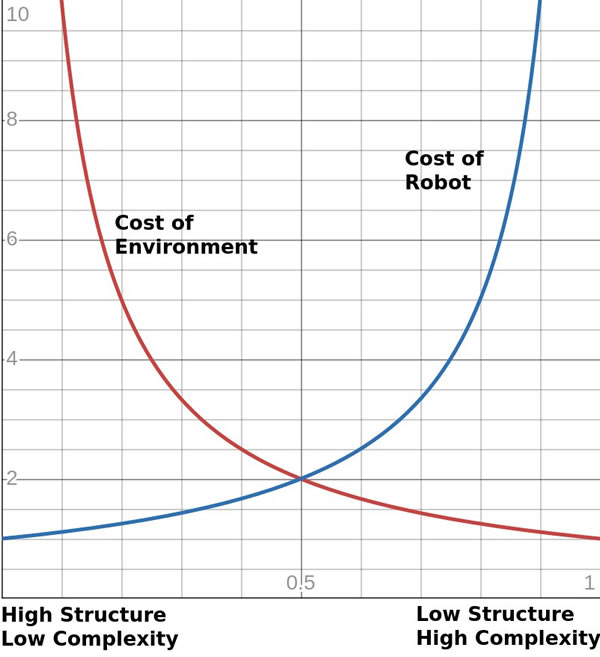

Every automation challenge has a huge locus of solutions (and a corresponding number of solutions destined to fail), but all the possible solutions exist along a spectrum between environmental structure and machine complexity.

Engineers must choose how much structure to apply to the environment and then build a robot capable of operating within that structure.

Every point along the x axis represents a technically feasible solution. However, where the lines cross represent both the least cost and least effort. As an investor or a founder, this is the first step to judging a business or product. How close is this design to the minimum balance?

Lessons from the Field

Here are some examples

- Warehousing: Purpose-built systems focused on narrow, repetitive tasks, like known item picking in structured zones can deliver strong ROI. If it is possible to specify what is getting picked up and what orientation it is, that system is simple and cheap. If you can’t afford an environment to meet those requirements AND you must pick up any arbitrary item in any orientation, that is extremely difficult, and your robot becomes extremely expensive.

- Food and Beverage: A soda fountain is a great simple machine. It forces a cup to be in the correct location and is flexible to the amount poured. It also handles spillage easily alleviating the need to measure quantities. A robot arm replacing a fry cook is both difficult to implement and extremely expensive. It has a horrible balance of environmental structure and robot complexity.

What Investors Should Look For

Investors play a pivotal role in shaping the robotics ecosystem. Here’s how to identify opportunities with real potential:

- Follow automation not the robot. Ignore the flash. Focus on startups that can demonstrate measurable savings, throughput gains, or revenue growth.

- Interrogate the environment. Understand the structure of the deployment environment. Can you easily think of a design with a better balance?

- Assess robustness. Ask for real-world performance data: uptime, maintenance requirements, and performance in edge cases.

Guidance for Founders

Founders can set themselves apart by focusing on fundamentals:

- Start with the process. Map the workflow first and focus on balance. If you choose less of one side, you will always need more of the other.

- Iterate toward balance. Your first guess at the balance will not be correct. Watch the progress and it will guide you toward a better balance.

- Prioritize reliability. Automation exists to handle repetitive tasks. If the system isn’t robust, not only will you not have customers, but you’ll also probably have lawsuits.

Looking Ahead

The future of robotics isn’t humanoids walking through our living rooms or choreographed demo videos going viral on social media. It’s the quiet, practical march forward of automation. The drum beat of progress has moved on relentlessly for the last 200 years. We just need to look at what that history teaches us, and we will find the next innovations. This knowledge allows us to differentiate between hype and promising ideas. This is where robotics finally earns its crossroads, the point where real choices and lasting progress become possible.

Chris Wardman serves as a fractional CTO and embedded systems expert, helping organizations bridge the gap between early prototypes and scalable, manufacturable products. He has led hardware/software integration across industries—from robotics and satellites to drones and autonomous systems—building the processes, teams, and technical frameworks that enable companies to innovate faster and bring complex products to market.

Chris Wardman serves as a fractional CTO and embedded systems expert, helping organizations bridge the gap between early prototypes and scalable, manufacturable products. He has led hardware/software integration across industries—from robotics and satellites to drones and autonomous systems—building the processes, teams, and technical frameworks that enable companies to innovate faster and bring complex products to market.

Featured Product