Sensing the Shift: Trends in Smart Industrial Automation

Over the past few years, the industrial automation market has experienced significant growth. There is increasing demand for productivity, uptime and additional output. Machines need to be turned on more quickly and for longer. Scaling operations must be done even more rapidly, and introducing new lines has to happen even faster than it would have in previous years.

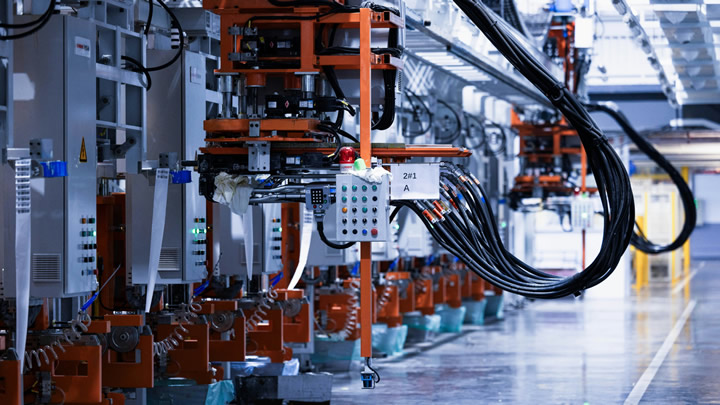

All of this accelerates the industry's need for smarter industrial automation, from vision and sensing to connectivity to the cloud, access to data, and the ability to manage factories remotely. Here at DigiKey, we are excited by the growing demand and technological innovation we are seeing on factory floors around the world. Cutting-edge robotics, sensors, edge computing, IoT and more are at the forefront of smarter manufacturing, bringing together the technology, infrastructure and innovation that power modern automation.

Robotics and Robotic Cells

In an automation environment, robots improve repetitive tasks, precision, consistency and uptime across processes. They remove inconsistent movements and improve safety in hazardous environments. Robots and cobots also elevate the workforce, allowing skilled labor to shift into roles that enable manufacturers to scale and adjust outputs.

Whether in maintenance and repairing or programming and configuring machines, automation also plays an important role in supporting labor shortages. As demand grows faster than the workforce, automation enables manufacturers to scale without solely relying on labor availability. That does not mean manufacturers rely completely on robots without skilled labor because robotic systems still need maintenance. Nothing is completely autonomous. Manufacturers still need people working alongside machines, but in a re-envisioned way that supports consistent output and reduced training overhead.

Robotic cells, enclosed workstations that combine robots and other tools, allow manufacturers to build safer and more efficient systems. One of the most important advantages they offer, whether it is assembly, welding, inspection or material handling, is precision around repetitive tasks.

These cells also improve manufacturing consistency. For example, if a process error occurs and a batch is incorrect, reviewing the data and tracing it back to a specific lot, robot or time of day can pinpoint what changed in the environment. Tracing back errors, identifying what changed in the data and removing it from happening in the future allows for added efficiencies and visibility.

Suppliers like Eaton are at the forefront of advancements in robotic cells with intelligent power management and circuit protection that provide safe, reliable automation. With Eaton’s distributed controls and smart circuit breakers, manufacturers can perform predictive maintenance and real-time diagnostics to reduce unplanned downtime and improve plant safety.

Advanced Sensing

The latest advancements in sensor technologies, data acquisition systems and communication protocols are also shaping the future of smart automation. As the pace of innovation accelerates, understanding these emerging technologies is crucial for manufacturers to stay ahead.

Advanced sensing options, whether they are optical, infrared, inductive, LiDAR or ultrasonic, are game changers in allowing manufacturers to better understand the environment in real time on the factory floor. Manufacturers are mixing solutions that measure and monitor performance, accuracy and range to capture everything happening instantaneously. Leading suppliers like SICK are developing smart sensors and vision systems that are flexible and traceable, especially in high-speed and collaborative environments.

Safety sensing technologies, such as light curtains, emergency stops, and safe motion control, help manufacturers interact with the equipment and the surrounding environment. For example, the ability to establish warning zones to alert workers approaching a hazardous area before they get too close can be a significant benefit. It prevents workers from accidentally entering the hazardous area, tripping a safety device and turning off a machine.

Key Trends in Industrial Automation

As we look to the future of smarter industrial automation, we are keeping our eyes on some exciting trends.

- Edge computing: AI will continue to move closer to the source, working even nearer to sensors and other machines. Especially for vision systems, the closeness between AI and the source improves the ability to detect what is actually happening and act at the source, essentially eliminating the current delays of data going to a control unit for processing and then sending analysis back to the source.

- Wireless connectivity: Advances in the industrial internet of things (IoT) will allow manufacturers to identify and correct problems and inefficiencies sooner, saving them time and money. The improvements in connections between sensor data, machine-to-machine communication and automation technologies provide machine learning technologies with more accurate data to optimize and streamline industrial processes. We expect to see significantly more physical protocols available from leaders in industrial Ethernet standards for automation technology like PROFINET and Modbus, along with single open, scalable Ethernet-based networks like Single Pair Ethernet (SPE). Advances in protocols will continue to reduce complexity and cost, enabling these sensors and communication devices to go beyond existing borders.

- Safety-integrated automation: It is easy to scale up operations quickly due to the return on investment of getting machines up and running. However, the gains made by scaling rapidly can disappear if there are any safety impacts on the labor force. The practice of integrating safety automation equipment alongside the rest of the automation in real time, not after the fact, is a growth area we are excited to support.

- High-mix, low-volume (HMLV) manufacturing: The industry seems poised to have a full circle moment with trend-flexible modular systems. The system that fell out of favor when Henry Ford was trying to balance his automobile assembly lines is now supported by adopting increased amounts of automation. Recent advances in industrial automation can offer quality customization and numerous configurations more efficiently and effectively without the strain of a specialized, dedicated labor force.

- Digital twins: The integration of simulation-driven design with machine learning and data analytics allows engineers to test, refine and perfect designs before they are physically realized or when they are in operation and positioned to benefit from continuous optimization. Digital twins can significantly improve design quality, cost and even safety and cybersecurity. Here at DigiKey, we are using digital twins to constantly monitor the flow in our product distribution center. Simulated design around packaging, orders and distribution gives the team insight into where hiccups might be occurring so we can reduce bottlenecks and boost performance in real time.

The growing demand for smart automation is not slowing down. Across the industry, there is heightened interest in e-commerce distribution partners like DigiKey. Engineers, designers and manufacturers are increasingly opting to shop for automation products and cutting-edge technologies from our frictionless website that has everything they need, along with delivery in as little as 24 hours.

The future of industrial automation is not just smart, but is agile and safe. DigiKey is committed to bridging the gap between innovation and execution, making it easier for customers to automate smarter, faster and safer.

For more industrial automation information, resources and products, visit www.digikey.com/automation.

Connor Doherty is the director of industrial automation at DigiKey. DigiKey is both the leader and continuous innovator in the high service distribution of electronic components and automation products worldwide, providing more than 16.5 million components from over 3,000 quality name-brand manufacturers.

Featured Product