Top 5 Global Robotics Trends 2026 - International Federation of Robotics Reports

CES 2026 | Linkerbot: 80% Market Dominance, Thousand-Unit Monthly Output

Robot-Driven Manufacturing Enables "Lights-Out" Production

RealMan Robotics Showcases Embodied Intelligence Infrastructure at CES 2026

Universal Robots and Robotiq Showcase Next-Generation Palletizing Solution at CES 2026 in Collaboration with Siemens

PI at Photonics West: See the Latest Advancements in Nanopositioning Automation and Precision Motion Control

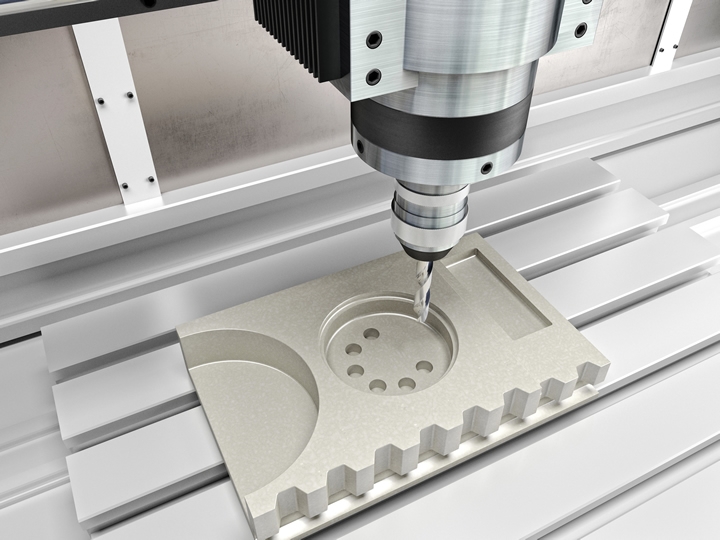

Robotecki Redefines Robotics Precision Cutting and Drilling Applications with RoboDK

Lanner Unveils EAI-I351: Next-Generation Robotic AI Platform Powered by NVIDIA Jetson Thor and NVIDIA Blackwell Architecture

Qualcomm Introduces a Full Suite of Robotics Technologies, Powering Physical AI from Household Robots up to Full-Size Humanoids

The Role of Emotional Intelligence When Implementing Industrial Robotics

Hygienic High-Precision Robotic Solutions from Stäubli Live at IPPE 2026

New at Mouser: Infineon Technologies PSOC Edge Machine Learning MCUs for Robotics, Industrial, and Smart Home Applications

2025 Top Article - The Future of Machining: Key Trends and Innovations

StackTrax - The Industry's First Off-The-Shelf Dual Axis RTU

The Hiring Freeze Came First. The Robots Came After.

Records 31 to 45 of 12461

First | Previous | Next | Last

Industrial Robotics - Featured Product

TM Robotics - Shibaura Machine THE SCARA range

Robotics and Automation - Featured Company