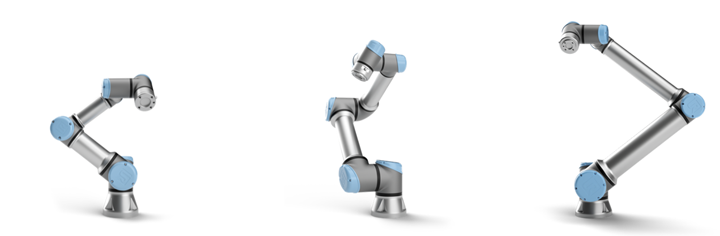

IMTS is the North American launch pad for our new flagship line of cobots, the e-Series. With e-Series, we raise the bar for cobots, strengthening the core principles that define collaborative robots: Visit us at Booth #236861 for more.

Stu Shephard | Universal Robots

Tell us about your company.

Universal Robots has reinvented industrial robotics with flexible, collaborative robot arms. We pioneered the technology and remain a frontrunner in the cobot market, delivering all advantages of advanced robotic automation with none of the traditional added costs associated with robot programming, set-up, and shielded work cells.

Your company will be exhibiting at IMTS, what is it that makes this an important event for your company?

IMTS is the largest manufacturing show in the nation and naturally a very important show for UR. Our business case is made in the personal interactions with visitors that in hands-on demos marvel at how flexible and easy our cobots are to program and operate. A show with 115,000+ visitors is a unique opportunity to deliver as many of these experiences as possible.

Highlight 2 or 3 products you will be showcasing at the event?

IMTS is the North American launch pad for our new flagship line of cobots, the e-Series. With e-Series, we raise the bar for cobots, strengthening the core principles that define collaborative robots: fast set-up, easy programming, flexible deployment, safe operation, and a quick ROI.

With a new built-in, tool-centric force/torque sensor, the e-Series is ready to take on popular collaborative robot applications that require force control right out of the box such as sanding, buffing, polishing and deburring where force-feedback is paramount in order to obtain uniform results. Increased repeatability of 30 microns (0.03mm) makes the new cobots suitable for precise finishing, assembly and electronics tasks.

A re-designed intuitive and responsive touch user expedites program development by reducing programming to a few clicks on a new lightweight, wide-screen teach pendant. At the same time, advanced users can utilize the new externally accessible 500Hz system bus to implement more complex motion control algorithms or profiles, such as advanced machine vision applications.

Our expansive, two-story booth will also feature a wide range of new plug & play products for the UR cobots, all developed and certified through the UR+ platform; new grippers, machine vision and metrology solutions, laser engraving and much more will be showcased on 20+ different cobots.

For attendees still wondering whether a lack of robotics programming experience will prevent them from integrating cobots in their production, we offer free UR Academy modules available both online and through big touch screen interfaces at the booth. The interactive training modules deliver the introduction necessary to master basic programming skills while more advanced users gain insights on how to create and work with coordinate systems, variables and conditional statements, and how to use the robot’s wizard to easily create a program for packaging.

IMTS has many educational sessions & demo’s, is your company involved in any of them this year?

Yes, our CTO and co-founder Esben Østergaard will be speaking in the conference portion of the show in a talk titled “Industry 5.0 – The Human Touch Revolution” on September 13 at 10am, discussing the perspectives and approaches that manufacturers need to adopt to meet the demand for “human touch” products. Esben was just awarded the “Nobel Prize of robotics” the Engelberger award for his pioneering work on cobots. Earlier in the week, on Wednesday September 12, I’ll be joining a panel on how robotics and AI are changing manufacturing at the Global Automation and Manufacturing Summit (GAMS) co-located with IMTS. Our President Jürgen Von Hollen will be doing an interview with IMTS TV on the new e-Series and we’re also appearing in a live recording on a panel with the Manufacturing Alliance Podcast at the show

When you get a chance to walk the exhibit hall floor yourself, what is it you will be most interested to see? Any educational sessions you plan on attending?

Universal Robots currently holds a 60% share of the global cobot market. Nowhere is that more apparent than at tradeshows where an ever increasing number of exhibitors now use UR cobots in new applications. I always look forward to walk the floor to visit the numerous booths of our Certified System Integrators, our UR+ partners and distributors, showcasing cobot-assisted demos. This year’s IMTS features more than 20 booths exhibiting our cobots.

When you book a booth for a tradeshow like this what are your expectations and what does your company hope to accomplish at the event?

We obviously hope that the many hands-on, eye-opening demos at our booth generate lots of leads for us to follow up on. The beauty of the UR cobots is their portability; we can literally pack them in the trunk of a car, wheel them into any manufacturing setting and demonstrate right then and there how the cobot would operate and perform in a given environment.

A tradeshow of this magnitude is extremely busy and stressful for the staff of exhibiting companies. Any fun things or places your team can suggest in Chicago to help unwind?

A tradeshow of this magnitude is extremely busy and stressful for the staff of exhibiting companies. Any fun things or places your team can suggest in Chicago to help unwind?

A tradeshow is a great opportunity for us to strengthen the UR ecosystem by inviting our partners and employees out to experience the town together. In the past we’ve done dinner cruises on the river, cheered for the Cubs at Wrigley Field, and dared each other to step out onto the plexiglass Skydeck on the 103rd floor of the Willis (former Sears) Tower.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product