Booth #4619 - ATI brings the MC-10 Manual Tool Changer and the new Universal Compliance Compensator (UCC) to PACK EXPO 2018

Contributed by | ATI Industrial Automation

Tell us about your company.

ATI Industrial Automation is a world-leading developer of robotic accessories and end-of-arm-tooling. Our expertly-engineered, productivity-enhancing solutions elevate automated processes through the integration of multi-tasking, collision detection, force sensing feedback, robotic material removal, compliance, and more. Simply put, ATI’s end effectors allow customers to do more with their automated processes.

Your company will be exhibiting at PACK EXPO, what is it that makes this an important event for your company?

PACK EXPO provides ATI with an opportunity to introduce our efficiency-enhancing solutions to packaging industry players. Automation and robotics are playing a significant role in advancing packaging technology and this show allows us to showcase our own flexible solutions and to observe trends and troubleshoot common problems customers face in the industry.

Highlight 2 or 3 products you will be showcasing at the event.

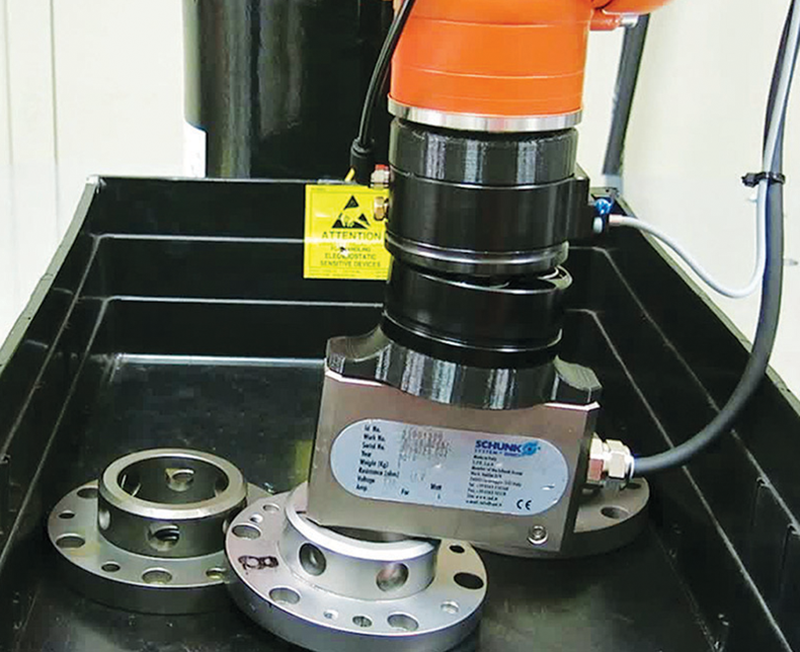

ATI brings the MC-10 Manual Tool Changer and the new Universal Compliance Compensator (UCC) to PACK EXPO 2018.

The MC-10 provides a simple yet robust solution for quickly changing tools by hand.

The UCC offers X-Y Lateral, X-Y-Z Rotation, and Z Compression to compensate for positioning misalignment.

When you get a chance to walk the exhibit hall floor yourself, what is it you will be most interested to see? Any educational sessions, pavilions etc. you plan on attending?

It is always exciting to walk the show floor and take in the creative demonstrations from our industry partners. A few of the special events we look forward to this year include the Packaging and Processing Women’s Leadership Network. ATI is proud to have many strong female leaders within our organization, and we love to see female empowerment on an international level. Of course, the Innovation Stage will be a hot destination for our show staff as well.

The factory floor is undertaking rapid advancements, be it automation, robotics, machine vision or data. The process of packaging is a huge part for many manufacturers, give us an idea on how your company and product is being utilized now in the smart factory.

ATI Universal Compliance Compensators (UCC’s) could offer robotic labeling systems a competitive edge. Integrating the UCC allows one robot the capability to place any label in any location on a package or pallet load. ATI’s UCC improves quality and uptime by compensating for skewed packages, sensing contact with the package, and offering adjustable label application pressure.

Give us your thoughts on what the future holds for manufacturers and packaging.

Collaborative robots have a lot to offer this market due to their high flexibility and safety as well as ease of use. ATI has developed a new manual tool changer, the MC-10 that is ideal for cobot applications. The MC-10 provides a durable, efficient method of changing tools by hand, thus enabling the execution of many tasks using multiple end-effectors within the same process. It handles payloads of up to 10kg and includes an option for passing utilities to the application with an add-on electrical module.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product