Visitors to the ATI Booth (B29074) will find a wide selection of Robotic and Manual Tool Changers, Force/Torque Sensors, Utility Couplers, and other end-effectors.

FABTECH Q&A with | ATI Industrial Automation

Tell us about your company.

ATI Industrial Automation is the world-leading engineering-based developer of robotic accessories and robot arm tooling, including Automatic Tool Changers, Multi-Axis Force/Torque Sensing Systems, Utility Couplers, Robotic Deburring Tools, Robotic Collision Sensors, Manual Tool Changers, and Compliance Devices. Our robot end-effector products are found in thousands of successful applications around the world. Since 1989, our team of mechanical, electrical, and software engineers has been developing cost-effective, state-of-the-art end-effector products and solutions that improve robotic productivity.

Your company will be exhibiting at FABTECH Expo, what is it that makes this an important event for your company?

The FABTECH show brings a very diverse crowd of attendees. This is great for ATI because we have a chance to connect with many of our customers while learning about our industry. We get to see our products at work in successful applications and discover new best practices. It’s always one of our most anticipated events of the year.

What makes your booth a must visit for FABTECH Expo Attendees?

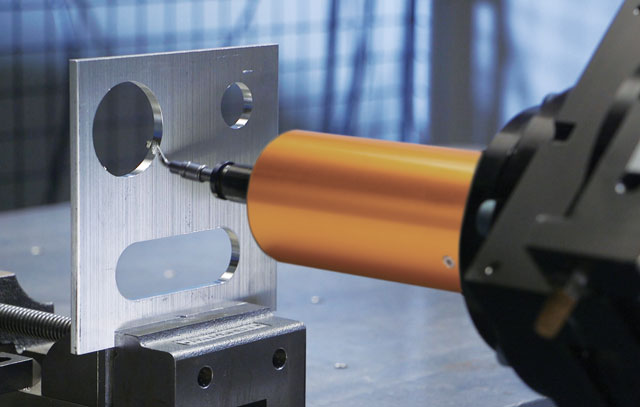

Visitors to the ATI Booth (B29074) will find a wide selection of Robotic and Manual Tool Changers, Force/Torque Sensors, Utility Couplers, and other end-effectors. ATI’s Material Removal product group is rapidly developing new tools as well. There are many opportunities to integrate simple and effective automated solutions within material removal applications that result in safer working conditions and more consistent processes. Be sure to check out what’s new in the Material Removal product family. It may spark your creativity…

FABTECH Expo has many educational sessions, forums & Demo’s, is your company involved in any of them this year?

We look forward to the Leadership Exchange on Monday for a stimulating discussion from a great group of panelists. The Smart Manufacturing Hub and 3D/Additive Manufacturing Pavilions will be must-see destinations for our staff as well.

When you get a chance to walk the exhibit hall floor yourself, what is it you will be most interested to see? Any educational sessions, pavilions etc. you plan on attending?

I enjoy the opportunity to catch up with ATI customers and see how they are using our products. We don’t always know how the equipment we sell will be integrated into a system, so it is exciting to see just how innovative our industry can be. The chance to see new technology at work, things that really surprise and impress, is my favorite part of any FABTECH show.

The Advanced Manufacturing is undertaking rapid advancements, be it 3D Printing and the materials used in automation and robotics. Automation Technology is a huge part for many manufacturers, give us an idea on how your company and product is being utilized now in the smart factory.

The biggest shift we see from customers is toward more flexible solutions. They want systems and processes that support a variety of tasks. ATI’s Automatic Tool Changers enable the use of different end-effectors within a single cycle with minimal changeover time. ATI’s Force/Torque Sensors help robots plug into their environment through force feedback. It allows them to be a more active part of the application. Many of ATI’s Material Removal Tools are designed with adjustable compliance force to accommodate many different types of materials and finishes. Our customers want to accomplish more with automation and they do it by integrating solutions that can serve more than one purpose.

Give us your thoughts on what the future holds for manufacturers and automation technology.

We believe the trend towards flexible manufacturing solutions will continue as automation penetrates new markets. While characteristics of these emerging industries differ, there is a lot of overlap among the types of processes and applications that are adopting robotic and automated technology. We can apply problem-solving techniques our customers trust in new ways. At the core of our business, ATI seeks to help our customers work smarter, not necessarily harder. We do this by creating solutions that improve robotic productivity and process efficiency.

If you would like please provide contact information for a reader to setup a booth demo.

To setup a booth visit or demonstration, contact Charles Haines, ATI Marketing Manager chaines@ati-ia.com.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product