Where motion is the key to a great cup of coffee, duplicating the precision and reliability of the motion of a person’s hand, wrist, and elbow require a unique robotic design.

Engineered to the Last Pour

Engineered to the Last Pour

Case Study from | maxon group

People love their coffee. Providing a consistent and reliable cup of coffee from a coffee shop often takes a lot of time in training your baristas. Gaining that same precision motion control combined with speed and reliability was the utmost challenge for Poursteady’s Chief Engineer, Stuart Heys, who has always loved a good challenge. I got to talk to Maximilian Babe, Poursteady’s Jack of all trades and current manufacturing manager about the final products.

Poursteady manufactures two different models. The PS1 five-station machine and the PS1-3c three-station machine. Each Poursteady machine automatically produces the perfect pour-over coffee based on the barista’s precise needs. “We wanted to design a tool that the baristas wanted to use, one that would give them the perfect cup of coffee every time while they made sure the grind was just right and that the customer was being well taken care of.” To do this, Stuart and the Poursteady team needed components that were not only accurate, but highly reliable, and offered long life. “Our machines have literally made millions of cups of coffee without a breakdown.”

The idea was for the machine to only automate the steps in making perfect pour-overs that made sense. This means that the recipes are variable depending on what the baristas choose to program into the machine. Hundreds of formulas can be stored and can be perfectly repeated with the push of a single button. Water is measured to the gram.

The robotic system provides the shapes and sizes of the spirals that are poured. Precise motion in multiple directions along with precise timing of each step is tracked and executed by the machine — using the Technosoft VX Intelligent Drive — for up to five cups at a time. Each cup can have a different sequence based on its program. Any combination of pour and motion is possible. This not only allows baristas to do other work and help customers in another way, it reduces the training the coffee shop owner needs to provide. And, it allows the shop to make more cups of coffee in less time, getting through a line of customers faster and more efficiently.

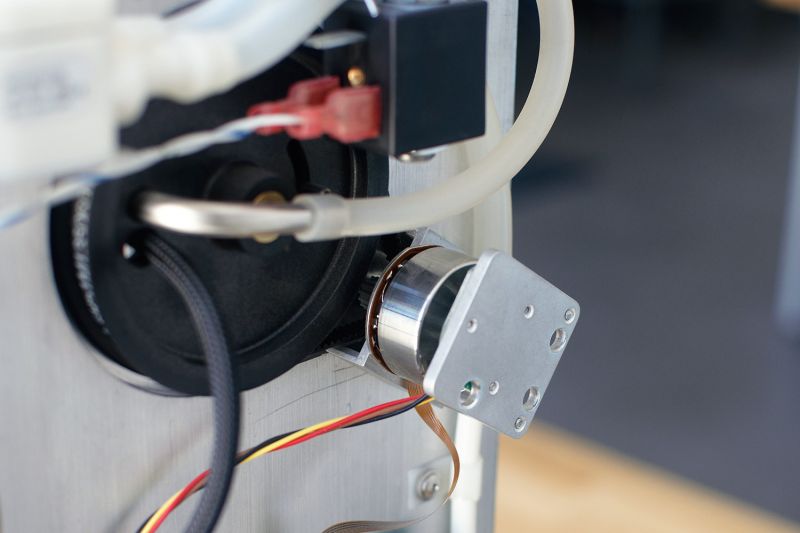

Stuart is a robotics engineer, and he used industrial automation components rated and tested for years of continuous use. Both machines use the same motion control components. Using two motors and three belts, the machine is able to manipulate the pour spout any way it chooses. The 3c machine is around 24 inches long, which is much narrower than an espresso machine. One belt runs the full length of the X axis of the brewer. It attaches to a gear and pulley design where a second belt runs from the pulley to the motor shaft, all inside the cage of the system. The Y axis is connected directly to a motor that sits outside the cage and pivots back and forth dependent on the controller signal programmed into the unit.

The combination of motions from the design allows a user to program the unit for any type of flow — simply back and forth along one axis or a wobble along one or two axes, or a circular pattern that can be adjusted for width as well as shape.

maxon EC-45 and EC-32 Flat Motors are used in the X and Y (tilt) axes for both the PS1 and PS1-3c Poursteady coffee brewers.

The motors used in the PS1 and PS1-3c include the 30 Watt, EC45 Flat motor for the X axis and the EC32 Flat motor for the Y (or tilt) axis. The motors are electronically commutated, thus enabling extremely long motor life, since there are simply no mechanical brushes to wear out. Hall effect sensors are built into some motors in order to provide feedback to the control electronics. The motors offer good heat dissipation and high overload capability. Both the EC45 flat and EC32 flat motors have a stainless-steel housing, vary widely in diameter, and offer different shaft lengths as well. The motors can be used at any speeds needed to accommodate the application. The dynamic load of the nozzle that is always moving during the pour sequence, is light and requires little torque. Precision of the operation is what’s important, and Poursteady acquires that through the use of a closed loop control system.

“We are not the experts on how a particular shop, or barista, should prepare their coffee. With the Poursteady machine the flexibility is there for the user,” Maximilian explained. Whatever coffee, roast, and dripper preferred can be set and saved in a recipe file. If a user finds they can’t get the perfect pattern on their unit, Poursteady will help provide a custom pour pattern for them.

The next goal for the company is to provide a way to make a one-minute cup of pour-over coffee. This would allow a barista to make over 100 cups of coffee per hour with a single operator and therefore reduce customer wait time, allowing for a better barista-customer experience overall.

If you like this article you may like "Smart Gripper for Small Collaborative Robots"

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

maxon group

maxon is a leading supplier of high-precision DC brush and brushless servo motors and drives. These motors range in size from 4 - 90 mm and are available up to 500 watts. We combine electric motors, gears and DC motor controls into high-precision, intelligent drive systems that can be custom-made to fit the specific needs of customer applications.

Other Articles

Multi-axis motion control drives pipe-based robots

Automate 2025 Q&A with maxon group

Understanding Torque and Speed in Electric Motors

More about maxon group

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product