Food Robotics - Transforming the Future of Food Processing

The opportunities within the Food Robotics market are vast, with potential for substantial advancements in robotic systems that can handle delicate food items, improve packaging efficiency, and innovate food assembly processes.

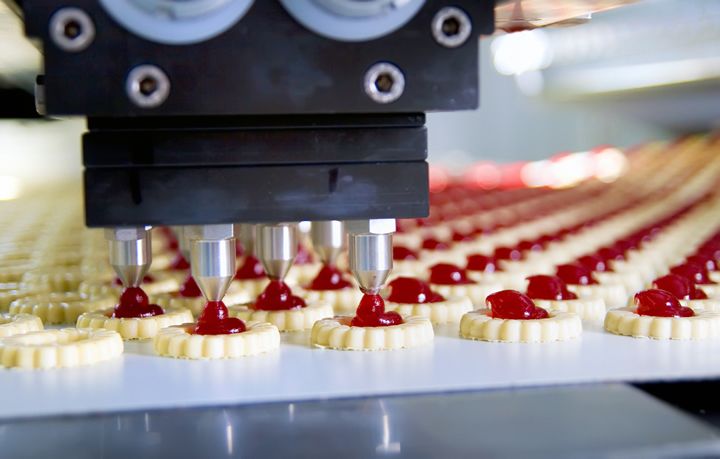

Automating pick-and-place in food manufacturing

The requirements included automatic pick and place of up to 60 keys per minute, seamless integration with the existing production line and a minimal factory floor footprint.

Building Customers' Trust With Robots - Advanced 3D Vision Systems Improve Food Traceability

Food traceability is not just a matter of compliance, it's also essential for maintaining customer trust and brand reputation.

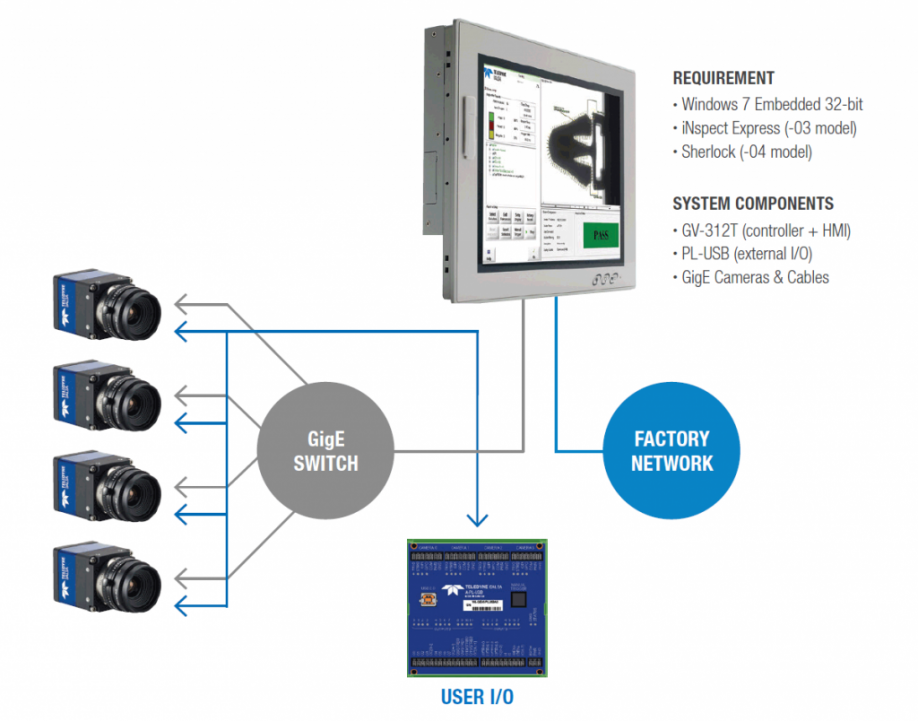

Kibele-PIMS Shows How Imaging Ensures Food is Reliably Sorted and Packaged

Fully Automated Packaging Systems Use Reliable, Durable Cameras to Ensure Sufficient Resolution and Speed for Flawless Sorting and Packaging

2022 Top Article - World's Largest Pasta Production Plant a Showcase for Integrated Robotics and Sustainable Distribution

Designed, manufactured and installed by E80 Group, this distribution facility is not only an example of excellence in integrated robotics systems, but also a showpiece for energy and environmental efficiency.

A Chilly Environment - Freezer & Refrigerated Automation & Efficiency

Recent advances in robotics and artificial intelligence (AI) have made it possible to automate many processes that were once thought to be too delicate or complicated for machines. So what is stopping cold chain businesses from taking advantage of these technologies?

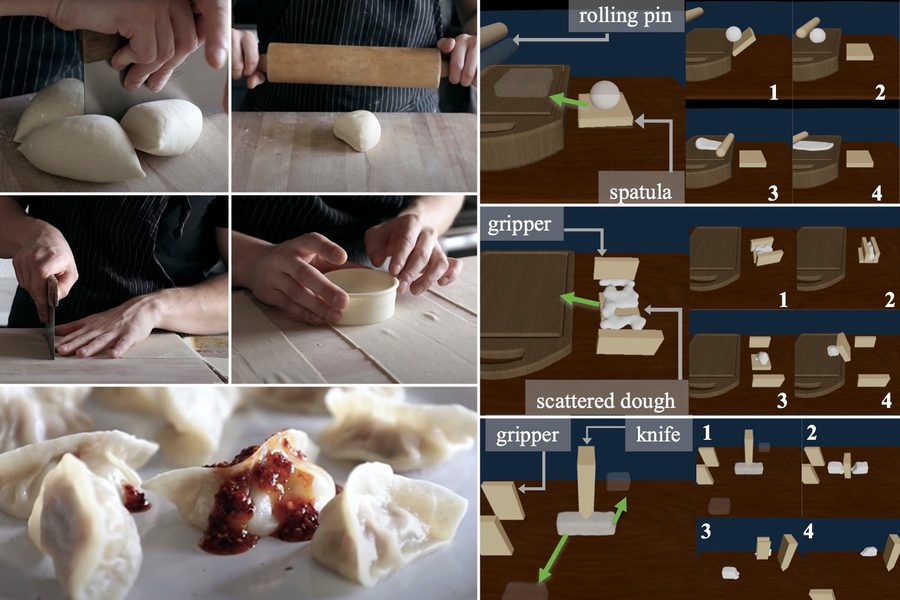

Solving the challenges of robotic pizza-making

A new technique could enable a robot to manipulate squishy objects like pizza dough or soft materials like clothing.

Flexible Robotics Facilitates High-Speed Cheese Packaging at Masters Gallery Foods

From pick-and-pack to palletization, Master's Gallery Foods relies on flexible robotics systems from Quest Industrial to streamline end-of-line packaging throughput at its six Wisconsin cheese maturation facilities.

Food Robotics Market to Hit $2 Billion by 2028

A recent report from Meticulous Research found that the food robotics industry is anticipated to grow to an astounding $2 billion by 2028. This growth indicates a turning point in the food industry, driven by a number of rising global concerns and trends.

Robotic Washdown in Food-Handling Environments

Heavy washdown and harsh chemical solutions used to clean robots in FDA and USDA sanitary environments for food processing can impact the robot finish, as well as leave condensation on robotic machinery that could potentially reach food products

being handled.

Robots in the Food Service Industry

The future of fresh, fast food is in robotics. In the not-so-distant future, robotic food automation systems will line the checkout areas and hallways of our major retailers, food courts, airport terminals, hospitals and universities.

Seafood Processors Turning to Robotics And Automation

New developments in robotics - including smart robotics, collaborative automation, and similar technology - may be essential for processors handling these modern challenges.

Case Study: A Coffee with the Robot

A company from Baden (region in Germany) claims to revolutionize the coffee-to-go gastronomy with its robotic coffee solution. With its gripper for handling coffee cups, the Zimmer Group is making an important contribution to this.

Karakuri unveils its first robotic canteen set to change the global food and hospitality industry

The UK robotics firm secures an additional £6.5m investment to develop ways to bring the fourth industrial revolution to the food industry

White Castle to Expand Implementations with Miso Robotics and Target Up to 10 New Locations Following Pilot

The world's first fast-food chain signs on for additional deployments of autonomous kitchen assistant - Flippy - to improve customer and team member experience in 'new normal'

Records 1 to 15 of 26

Featured Product

PI USA - Gantry Stages for Laser Machining and Additive Manufacturing

High performance gantry systems, from PI, are used in precision assembly, laser machining, and additive manufacturing. Complete with software and state-of-the-art EtherCat® motion controllers. Easy to program, easy synchronization with lasers and dispensers. Standard and custom, compact systems and large, granite-based units.

Robotics and Automation - Featured Company

Elmo Motion Control Inc.

Elmo has been a motion control technology leader for over 35 years, with millions of servo drives working 24/7 worldwide. Elmo offers complete motion control solutions from design to delivery of cutting-edge servo drives, network-based multi-axis motion controllers, and integrated servo motors. All solutions can be customized and configured using Elmo's proprietary advanced and easy-to-use software tools for any machine in any industry, such as semiconductors, lasers, robots, life sciences, industrial automation, AGV, and more. The company employs more than 350 personnel with headquarters in Israel and offices in the United States, China, Germany, Italy, Korea, Singapore, and an additional manufacturing facility in Poland. Elmo has a worldwide distribution network. By advancing motion control with state-of-the-art technology, Elmo makes smart machines even smarter. As of 2022, Elmo is a Bosch Rexroth company.

.jpg)