Continuous Improvement is often misunderstood as an engine for solving more problems. In reality, the defining capability of a mature operation is ensuring the same problems never return.

KPI Growth has an enemy called "Recurrence" - Fight it with Standard Work to Sustain the Growth.

Saloni Banani, Marketing Manager | OrcaLean

Many plants appear busy: actions closed, issues logged, RCAs held, meetings completed.

Yet PPM refuses to drop. Throughput swings every week. $/unit flatlines quarter after quarter.

Activity isn’t improving.

Permanence is.

Every recurrence restarts the cost clock: overtime, rework, containment, variation, unplanned downtime.

Continuous Improvement is often misunderstood as an engine for solving more problems. In reality, the defining capability of a mature operation is ensuring the same problems never return.

• PPM ↓

• Throughput ↑

• $/unit ↓

These shifts come not from problem volume, but from recurrence elimination.

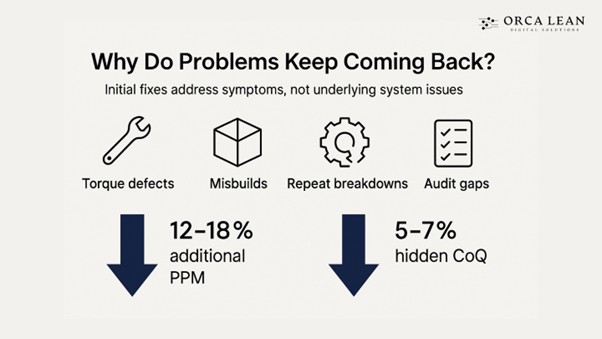

Why Do Problems Keep Coming Back Even After They're “Solved”?

Many issues reappear because initial fixes address the visible symptom, not the underlying system behavior.

Examples found across plants:

- Torque defects returning despite coaching

- Misbuilds resurfacing after “refresher training”

- Repeat breakdowns after simple part replacements

- Same audit gaps appearing across shifts

Recurrence adds 12–18% unnecessary PPM and 5–7% hidden cost of quality, driven by rework, containment, and repeated interventions.

When problems recur, the plant isn't suffering from volume — it's suffering from structural weakness in how problems are analyzed, verified, and locked into the process.

KPI lift: PPM ↓, CoQ ↓

The Problem Backlog Is Not the Real Issue — The Recurrence Loop Is

Plants often carry long action lists and assume it reflects the demand for more CI activity.

In reality:

70% of CI workload in typical factories is repeat work — earlier problems resurfacing in a new shift, new model, or new condition.

This creates a hidden loop:

- Problem occurs

- Temporary fix applied

- Workload appears closed

- Recurrence happens

- CI reopens the issue

- KPIs remain flat

This illusion of progress consumes resources without shifting any core metrics.

KPI lift: Throughput ↑, Schedule Attainment ↑

The Economics of a Recurring Problem: 3–5× the Cost of the First Incident

The first occurrence of an issue is rarely the most expensive. The cost escalates with each return.

First incident cost: rework, inspection, minor disruption

Subsequent incidents:

- Overtime to catch up

- Scrap from repeated misbuilds

- Throughput loss due to stop-start flow

- Customer exposure

- Expedited shipments

- Line variation that spreads downstream

On average:

- One recurring defect drains 8–12 hours of throughput across departments

- Recurrent scrap inflates $/unit by 3–7%

Recurrence is one of the fastest ways to destroy a margin without anyone noticing.

KPI lift: $/unit ↓, Scrap ↓, Throughput ↑

Explore how to Build a Continuous Improvement Culture in American SMEs in 6 Steps.

The Illusion of “Closed Actions” — Controlled, Not Eliminated

Many plants track “Closed” actions as proof of improvement. But a large share of closed actions are actually:

- Containments

- Short-term workarounds

- Inspections

- Coaching

- Additional checks

- Temporary standard adjustments

These suppress symptoms but do not remove causes.

They create a short-lived dip in PPM, often lasting 48–72 hours, followed by a rebound.

A high “action closure rate” is often the most misleading metric in CI.

Without permanent change in how work is done, closure = pause, not resolution.

KPI lift: PPM ↓, FTQ ↑

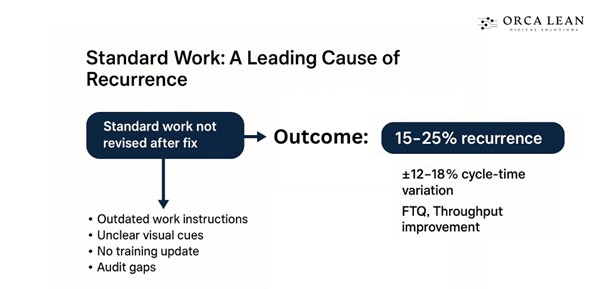

Standard Work Is the First Place Where Recurrence Is Born

Most recurrences can be traced back to one pattern: The standard didn’t change after the fix.

RCA was completed, but:

- Work instructions stayed outdated

- Visual cues remained unclear

- Training wasn’t updated

- Audit points didn’t reflect the new method

- Expectations varied by shift

The result?

15–25% of recurrence comes directly from un-updated Standard Work.

Cycle-time instability from missing standardization adds ±12–18% flow variation, destabilizing throughput and reliability.

When Standard Work doesn’t evolve, improvements cannot survive.

KPI lift: FTQ ↑, Throughput ↑

Symptom Fixes Create the Most Dangerous Pattern: False Improvement

When a problem resurfaces shortly after being “closed,” the cause is often a shallow intervention.

Symptoms addressed:

- Coaching an operator without clarifying the process

- Replacing a part without addressing why it failed

- Adding an inspection step instead of eliminating the condition

- Increasing checks instead of redesigning the method

These fixes create short-lived improvement windows: 30–72 hours of KPI calm before the issue returns.

From a KPI standpoint, the impact is negligible.

A factory full of symptom fixes always feels “busy,” never “better.”

KPI lift: Line Efficiency ↑, PPM ↓

Improvements That Don’t Become Standards Are Lost Within 90 Days

Without integration into Standard Work, improvements fade because:

- Training remains outdated

- New hires follow the old method

- Audits don’t enforce the new steps

- Visual controls don’t change

- Shift leaders revert to familiar practices

Data across multiple plants shows:

- Only 18–25% of improvements survive without standardization

- 75–85% survive when embedded into training + work instructions

Continuous Improvement that doesn’t convert improvements into standards is simply documenting progress, not creating it.

KPI lift: FTQ ↑, PPM ↓, $/unit ↓

What Happens When a Factory Eliminates 50% of Its Repeat Problems?

Most plants underestimate the scale of what recurrence removal unlocks.

When 50% of recurring problems are eliminated (achievable within 90 days with system discipline):

- PPM drops 35–45%

- Throughput increases 6–12%

- $/unit falls 4–8%

- Line stability improves across all shifts

- Audit findings collapse by 30–40%

This is one of the highest ROI levers in operations — faster than automation, cheaper than capacity additions, and more reliable than staffing interventions.

KPI lift: All Level-1 KPIs (FTQ, PPM, Throughput, $/unit)

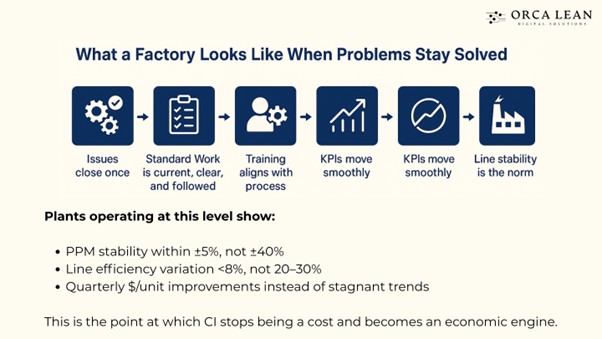

What a Factory Looks Like When Problems Stay Solved?

Mature recurrence control creates a visibly different plant:

Conclusion — True Improvement comes From Solving problems in a way that they dont return.

Real operational gains don’t come from the sheer volume of problems solved. They come from the absence of recurring issues — the point at which defects stop resurfacing, flow stops collapsing, and resources stop being drained by repeat waste.

When recurrence disappears:

- PPM stabilizes and drops because the underlying conditions stop resetting.

- Throughput becomes predictable because the line no longer absorbs the same disruptions.

- $/unit declines quarter after quarter because rework, variation, and re-solving vanish from the cost structure.

A factory that removes recurrence isn’t just improving — it’s compounding.

This is where CI stops being a cost center, a reporting routine, or an activity log… and becomes an economic engine embedded into the way the plant runs every day.

If you’re exploring how to build a recurrence-free operating system in your factory, we’re always open to a conversation.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product