The Stefa Mini, Cassette and Nano Seals all have smaller cross sections than comparable seals in the market today. This matters because a smaller seal allows for smaller glands (the area the seal slips into on the equipment) and smaller glands mean overall smaller equipment.

Stefa Mini Solutions for Next-Generation Robotic Applications

Stefa Mini Solutions for Next-Generation Robotic Applications

Product Q&A with David Kaley, Global Segment Manager for Industrial Automation | Trelleborg Sealing Solutions

Tell us about your product and what you feel sets it apart from similar products.

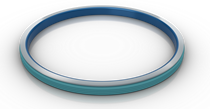

The biggest differentiator for the Stefa® Mini Radial Shaft Seals portfolio is its compact size. The Stefa® Mini, Cassette and Nano Seals all have smaller cross sections than comparable seals in the market today. This matters because a smaller seal allows for smaller glands (the area the seal slips into on the equipment) and smaller glands mean overall smaller equipment.

With robots, especially those in manufacturing and packaging, speed and accuracy drive profit. If the housing of the robot, motor or gearbox is smaller, it reduces the overall weight of the robot. This reduced weight allows the robot to move and stop using less energy while increasing speed. Additionally, less weight means reduced momentum which helps the robot settle faster when stopping or changing direction. This reduces overall vibration potentially helping improve accuracy and speed.

The Stefa® Mini Radial Shaft Seal portfolio is designed to meet the evolving demands of the robotics industry. By leveraging cutting-edge materials and advanced designs, this range of seals provides robust performance, extends maintenance intervals and improves energy efficiency. This ultimately helps robotics manufacturers enhance their product offerings and maintain their competitive edge in a fast-paced global market.

The Stefa® Mini Radial Shaft Seal is designed with a compact .197 x .197 inch/5 x 5 millimeter cross-section and is available in diameters ranging from .393 to 3 inches/10 to 100 millimeters.

FEATURES AND BENEFITS

• Excellent sealing performance

• Long service life extends maintenance intervals

• Significant space and weight-savings with proprietary miniature design

• Energy efficient

• Designed for complex, accurate, fast movement

• Low-friction properties

• Excellent chemical compatibility

• Produced with proprietary Trelleborg compounds, food-grade and PFAS-free formulations available if needed

Tell us about the R&D behind this product. Who is this product designed for? What problem is it solving?

A seal's main challenge is to work effectively from day one and continue doing so. It must retain oil or grease and block contaminants, performing reliably beyond initial commissioning.

A seal's main challenge is to work effectively from day one and continue doing so. It must retain oil or grease and block contaminants, performing reliably beyond initial commissioning.

We tested the functional performance of our seals over 5,000 hours of running time, well beyond the highest target of our customers for seal longevity. 5,000 hours is not the expected seal life; this is the value used to validate the seal’s performance. In real world applications, it could be much longer or shorter depending on the application and the operating environment.

We subjected our seals to an extremely accelerated cycle, a significant challenge that combines speed and longevity with high acceleration. Our functional tests on the Stefa® Mini Radial Shaft Seals were designed to assess performance and durability under demanding operating conditions. We also disrupted the fluid film to evaluate the seal’s resilience with poor lubrication. Additionally, we simulated extreme wear conditions to analyze the seal’s response to high stress levels.

We subjected our seals to an extremely accelerated cycle, a significant challenge that combines speed and longevity with high acceleration. Our functional tests on the Stefa® Mini Radial Shaft Seals were designed to assess performance and durability under demanding operating conditions. We also disrupted the fluid film to evaluate the seal’s resilience with poor lubrication. Additionally, we simulated extreme wear conditions to analyze the seal’s response to high stress levels.

The Stefa® Mini Radial Shaft Seal family is specifically engineered for use in robotic joints, servo motors, direct drive motors, gearboxes and speed reducers, industrial automation equipment and servo gear motors.

Give us an idea on the installation process.

Installing a Stefa® Mini or Mini Cassette Radial Shaft Seal follows the same steps as any other type: grease or oil the mating surfaces then apply even pressure around the seal. Use of an installation tool is recommended.

Both the Mini and the Mini Cassette provide retention grooves to help the seal stay in place during operation. The Nano does require a split groove or gland to ensure the seal is retained properly.

How is your company set up to support the users of your products.

The Trelleborg Sealing Solutions Rotary Process Development Center in Turin, Italy brings product development, prototype production, validation testing and manufacturing together under one roof. With a focus on customer service, the facility integrates advanced simulation tools with innovative testing capabilities and places automation and efficiency at the heart of the manufacturing process.

Because of our global presence, customers can work with their local Trelleborg sales and application engineers and receive the same expertise and capabilities regardless of location. To engage with a Trelleborg sales representative, interested parties can fill out the “Contact Us” form on our website: https://www.trelleborg.com/en/seals/contact-form

What feedback have you received from the field? Can you share a use case and the results?

Initial feedback is very positive from customers who have decided to move forward with using Stefa® Mini Radial Shaft Seals in serial production. These customers put the seals through vigorous quality testing to ensure they worked in their product.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product