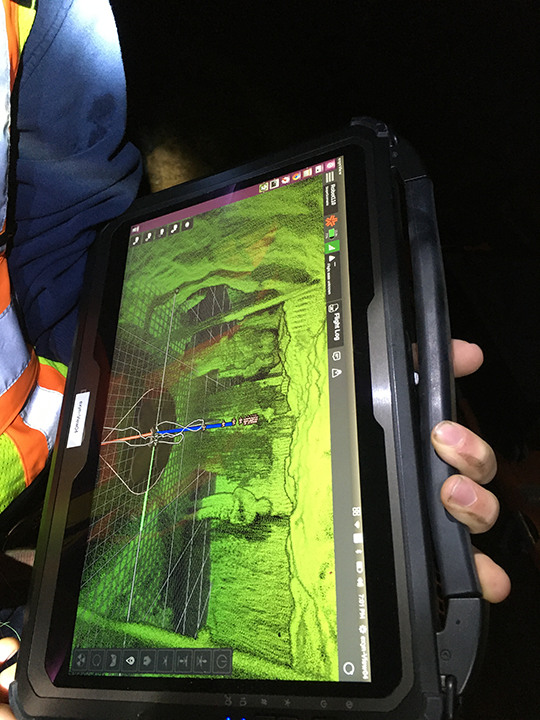

With Exyn's fully autonomous aerial drones, the team was able to navigate old workings and map them more accurately with drones that are able to independently navigate, visualize and record the whole space, even in the challenging environment.

Autonomous Drones Provide Information on Remaining Resources in Historic Mining Area

Autonomous Drones Provide Information on Remaining Resources in Historic Mining Area

Case Study from | Ascot Resources + Exyn Technologies

Ascot Resources geologists knew from surface drilling programs that there was still some gold in a mine area that had been inactive since the 1940s, but needed more information from old workings to determine how much resource potentially remained. Typically, surveying a previously active mine would be done by a specialist with handheld laser tools, but areas of the mine were inaccessible or unsafe for personnel. In the past, this would have meant leaving the old mine area closed or investing a large amount of money to make it safe prior to exploration. With Exyn’s fully autonomous aerial drones, the team was able to navigate old workings and map them more accurately with drones that are able to independently navigate, visualize and record the whole space, even in the challenging environment. The successful mapping operation provided Ascot Resources a new way for them, and other resource extractors, to accurately calculate extracted material in inactive mines.

THE PROBLEM

Ascot Resources was interested in collecting data from a long-inactive mine, last accessed in the 1940s. Although Ascot determined there was valuable data to be collected in that mine, the procedures were too costly and conditions were potentially too dangerous for human surveyors to perform—especially as Ascot wasn’t certain exactly what kind of data would be discovered in the mine. Additionally, older mines like this one are different than modern mines for a variety of reasons. Narrower tunnels and more limited vehicle access due to the constraints of 1940s technology presented logistical challenges for human teams that would attempt to survey the mine. Ascot wanted to remove the guesswork from the process of developing a map of the mine. As Ascot management weighed their options for accessing the mine, they turned to Exyn, developer of the world’s first truly autonomous aerial robot for GPS-denied environments, to collect real-time, high-fidelity 3D maps without the constraints that normally hinder other LIDAR based mapping approaches.

THE SOLUTION

The comprehensive maps created by Exyn’s drones were then cross-referenced against the historical map of the mine—helping Ascot Resources better determine exactly how much of the mine had already been excavated, and which sections potentially still contained valuable resource. Using Exyn’s technology, the process was not only safer and more cost-effective than if performed by human surveyors, but it provided a more complete map more quickly than alternative LIDAR-mapping solutions.

Ascot Resources management was then able to gather the data retrieved by Exyn’s autonomous drones in order to create a comprehensive report of existing mine openings, helping to determine how much gold there was left to be mined onsite to present to potential investors. Using such technology, Exyn can potentially reopen many other long-disused mines which may still have valuable materials inside, thanks to the smart drones being able to autonomously “see” the entire space.

If you like this article you may like "Is Software the Future of Robotics?"

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product