A mechatronic subsystem is a fully integrated functional unit that combines mechanical, electrical, electromechanical, and control elements into a single pre-engineered solution.

The Emergence of Mechatronic Subsystems and Their Importance in Product Deployment

Q&A with Warren Osak, President and Founder | Electromate

Tell us about yourself and your role with Electromate.

I’m the Founder and President of Electromate, a Canadian value-added distributor of high-performance motion control, mechatronic, and robotic solutions. I’ve been involved in the motion control industry for over 35 years, helping OEMs and machine builders deploy advanced automation technologies.

My focus is on enabling original equipment manufacturers to accelerate their development cycles by providing access to precision robotic and mechatronic components and subsystem-level solutions that reduce design complexity and shorten time to market.

Electromate was founded in 1986 with the belief that engineering time is best spent on innovation and research and development, rather than repeating existing engineering work.

What defines a mechatronic subsystem, and how do they differ from traditional component-level designs?

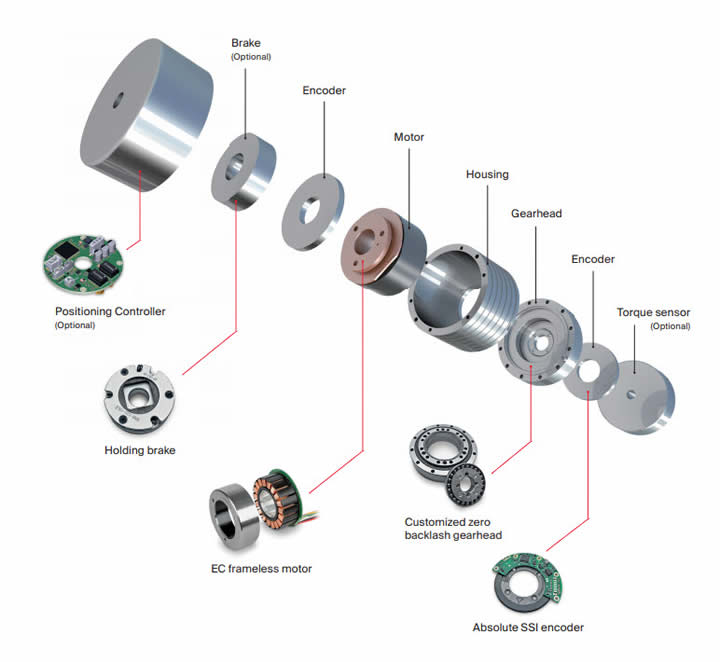

A mechatronic subsystem is a fully integrated functional unit that combines mechanical, electrical, electromechanical, and control elements into a single pre-engineered solution. It typically includes a motor, gearhead, encoder, drive, and sometimes an embedded controller—all optimized to work together out of the box.

In contrast, a traditional component-level design requires customers to source, integrate, and validate each element individually. This increases project timelines, risk, and complexity. Subsystems shift that burden upstream, providing a tested and validated building block that can be dropped into a larger machine or process with minimal customization.

What trends are driving the increased demand for integrated mechatronic subsystems across industries?

Three major trends are driving this shift.

First, there’s growing pressure to reduce time to market. Subsystems enable OEMs to bypass lengthy integration phases and proceed directly to application-level development.

Second, engineering teams are leaner than ever. Instead of allocating resources to component selection, tuning, and troubleshooting, companies are prioritizing solutions that deliver reliable performance out of the box.

Third, as machines become smaller with a smaller usable footprint, subsystems offer a compact, optimized way to provide packaged mechatronic performance. Vendors are now offering application-specific subsystems --such as Robotic Joints for exoskeletons and robots, AGV Wheeldrives, or UAV and Drone subsystems--where the mechanical, electrical, electromechanical, and software elements are all optimized for a single use case.

How do subsystems improve speed to market and reduce engineering overhead for OEMs and machine builders?

Subsystems eliminate many of the most time-consuming engineering tasks: sizing motors, matching feedback devices, tuning servo loops, and validating control interfaces. These are already handled at the subsystem level by the vendor.

Subsystems eliminate many of the most time-consuming engineering tasks: sizing motors, matching feedback devices, tuning servo loops, and validating control interfaces. These are already handled at the subsystem level by the vendor.

Instead of building functionality from scratch, customers can start with a platform that has been tested for reliability, thermal behavior, and electrical compatibility. This not only accelerates development but also reduces commissioning time, warranty risk, and support.

For OEMs building variants of a machine, subsystems also simplify replication and documentation, making it easier to scale production and service the automation equipment.

What are some challenges companies face when adopting subsystem solutions, and how can they be addressed?

The most common concern is loss of design flexibility. Companies accustomed to selecting every component may worry about being locked into a fixed solution. That’s why it's essential to select subsystems that are modular, well-documented, and permit interface-level customization where necessary.

Another challenge is confidence in long-term support. Because subsystems are integrated, any vendor design change can have a more significant impact. Mitigating this requires working with suppliers who offer stability, lifecycle visibility, and deep application knowledge.

We advise customers to treat subsystem vendors as strategic partners, not commodity suppliers. Subsystems save time and cost—but only when backed by strong engineering support and clear communication.

Can you share any use cases from companies you have worked with in adopting subsystem solutions?

We’ve worked with many machine builders who replaced in-house custom-built solutions with fully integrated motion or mechatronic subsystems. Many of these applications are shown at https://www.electromate.com/mechatronic-automation/mechatronic-systems/robotics/ and https://www.electromate.com/mechatronic-automation/mechatronic-systems/

In the collaborative robotics space, we’ve helped clients deploy integrated cobot joints that combine motors, encoders, gearheads, and safety-rated torque sensors. Instead of sourcing from four vendors, they received a single tested robotic joint assembly, greatly simplifying their design and certification cycle.

These are just two examples, but the typical result is the same: accelerated development cycle, reduced risk, and redeploying internal resources on new product innovation or differentiation rather than reinvention.

Where do you see the evolution of mechatronic subsystems heading in the next 3–5 years?

Subsystems are becoming more application-focused and data-driven. Vendors are beginning to offer pre-configured solutions tailored to specific functions, such as Robotic Joints for collaborative and industrial robots, and Wheeldrives for AMRs and AGVs. These aren’t general-purpose motion kits; they’re optimized for a specific use case.

We also see more subsystems being offered with embedded intelligence: condition monitoring, diagnostics, and even predictive maintenance features. Instead of just delivering torque, speed, or position, these subsystems offer insight into system health and performance, helping reduce downtime and service calls.

This evolution will make subsystems indispensable not just for prototyping or R&D, but for full-scale industrial deployment.

How does Electromate support its customers in selecting and deploying subsystem-level solutions?

Our engineering team works directly with customers to define performance requirements, environmental constraints, and control needs. We then recommend a subsystem architecture from our vendor network that matches those parameters. Electromate supports the sizing, selection, procurement, and integration of mechatronic subsystems across a wide range of industries, including medical and laboratory automation, embedded robotics, and material handling.

Post-sale Electromate provides technical support, documentation, and training to ensure the successful implementation and long-term performance of our mechatronic subsystem solutions. Our focus is on reducing project risk while accelerating product deployment.

.jpg) A renowned and respected Toronto based businessman for over 30 years, Warren Osak is the Founder & CEO of two Industrial Automation Distribution companies specializing in Robotics and Factory Automation. Considered a pioneer in his field, Warren was first among his peers to incorporate ISO and LEAN Quality Management Systems into his business processes, and led his industry's E-Commerce revolution with his USA expansion, Servo2Go.com. Servo2Go was also the first company in the Motion Control Industry to offer an AirMiles Loyalty Program.

A renowned and respected Toronto based businessman for over 30 years, Warren Osak is the Founder & CEO of two Industrial Automation Distribution companies specializing in Robotics and Factory Automation. Considered a pioneer in his field, Warren was first among his peers to incorporate ISO and LEAN Quality Management Systems into his business processes, and led his industry's E-Commerce revolution with his USA expansion, Servo2Go.com. Servo2Go was also the first company in the Motion Control Industry to offer an AirMiles Loyalty Program.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Servo2Go.com Ltd.

Servo2Go.com is an Online E-Store Distributor of Automation & Motion Control Systems & Components including: Servo Motors & Drives, Stepper Motors & Drives, Automation & Motion Controllers, HMIs, Positioning Systems & Actuators, Gearboxes, Couplings, Brakes, Encoders, Tachometers and Linear Displacement Transducers. Servo2Go.com is an ISO9001:2015 Registered Company.

Other Articles

Optimizing Servo System Performance: A Comprehensive Guide to Eliminating Electrical Noise and Enhancing Noise Immunity

The Importance of the Speed-Torque Gradient in DC Motor Sizing

Understanding the Motor Constant in DC Motor Sizing

More about Servo2Go.com Ltd.

Featured Product