LMI Technologies, in partnership with STT Systems and Stemmer Imaging, implemented an automated quality inspection system to detect missing bolts on automotive blanks. The system integrated multiple Gocator 3D sensors and an RFID tracking system for real-time analysis.

CASE STUDY STT SYSTEMS and STEMMER IMAGING: AUTOMOTIVE BOLT INSPECTION SYSTEM WITH GOCATOR SMART 3D LASER PROFILERS

Case Study from | LMI Technologies Inc.

Company Overview

STT Systems

Founded in 1998 in San Sebastián, Spain, STT Systems specializes in providing advanced motion analysis and machine vision solutions. The company supports industries such as biomechanics, sports, and industrial quality control. Their divisions—Visio (machine vision) and Motio (biomechanics)—develop and deliver customized software solutions, while their Creatio branch focuses on R&D in sensor technology, AI, and machine learning.

Founded in 1998 in San Sebastián, Spain, STT Systems specializes in providing advanced motion analysis and machine vision solutions. The company supports industries such as biomechanics, sports, and industrial quality control. Their divisions—Visio (machine vision) and Motio (biomechanics)—develop and deliver customized software solutions, while their Creatio branch focuses on R&D in sensor technology, AI, and machine learning.

Stemmer Imaging

Stemmer Imaging, an industry leader in machine vision, provides cutting-edge solutions for the inspection, measurement, and quality control of products in the manufacturing process. They work with clients across diverse industries, offering expert guidance in deploying imaging systems for complex automation challenges.

Stemmer Imaging, an industry leader in machine vision, provides cutting-edge solutions for the inspection, measurement, and quality control of products in the manufacturing process. They work with clients across diverse industries, offering expert guidance in deploying imaging systems for complex automation challenges.

The Challenge

In an automotive manufacturing facility at Seat Martorell (Volkswagen Group), the challenge was to ensure that automotive blanks—specifically, the metal components that would later form car parts—were properly inspected for the presence of necessary bolts. Missing bolts on blanks can lead to significant delays, costly rework, and potential assembly line stoppages. Detecting missing bolts as early as possible in the production line was critical to avoiding these issues. The inspection needed to occur right after the welding process, where bolts were welded onto the blanks, to minimize potential disruptions downstream.

In an automotive manufacturing facility at Seat Martorell (Volkswagen Group), the challenge was to ensure that automotive blanks—specifically, the metal components that would later form car parts—were properly inspected for the presence of necessary bolts. Missing bolts on blanks can lead to significant delays, costly rework, and potential assembly line stoppages. Detecting missing bolts as early as possible in the production line was critical to avoiding these issues. The inspection needed to occur right after the welding process, where bolts were welded onto the blanks, to minimize potential disruptions downstream.

• Identify missing bolts as early as possible to prevent delays and rework.

• Automate the inspection process to minimize manual intervention and reduce labor costs.

• Ensure traceability for quality control and data analysis.

The Solution

LMI Technologies, in partnership with STT Systems and Stemmer Imaging, implemented an automated quality inspection system to detect missing bolts on automotive blanks. The system integrated multiple Gocator 3D sensors and an RFID tracking system for real-time analysis and traceability.

LMI Technologies, in partnership with STT Systems and Stemmer Imaging, implemented an automated quality inspection system to detect missing bolts on automotive blanks. The system integrated multiple Gocator 3D sensors and an RFID tracking system for real-time analysis and traceability.

Key components of the solution:

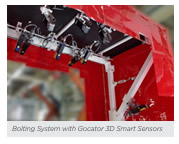

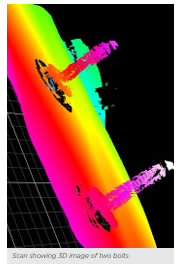

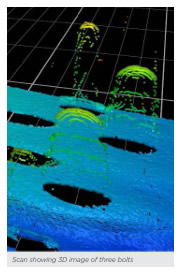

1. Gocator 3D Sensors: Multiple Gocator sensors, including the 2490 and 2380 models, were strategically positioned to scan the blanks from different angles and generate high-resolution 3D point clouds. This data was then used to identify whether each required bolt was present on the blank.

1. Gocator 3D Sensors: Multiple Gocator sensors, including the 2490 and 2380 models, were strategically positioned to scan the blanks from different angles and generate high-resolution 3D point clouds. This data was then used to identify whether each required bolt was present on the blank.

2. RFID Tracking: Each blank was equipped with an RFID tag, which was scanned automatically using antennas mounted along the production line. This enabled the system to associate the inspection results with the specific blank, ensuring complete traceability of each component.

3. Automation and Integration: The inspection system was fully integrated with the production line PLC (Programmable Logic Controller). Once the inspection was complete, the system could automatically decide whether to divert blanks for manual inspection or allow them to continue in the production process. If any missing bolts were detected, the system would communicate the required action for manual rework.

4. Database Integration: All inspection results were stored in a centralized database, allowing for historical data analysis, statistical reporting, and ongoing performance monitoring. The system provided traceability for each blank and gave real-time visibility into the production process.

The Result

The automated inspection system allowed Seat Martorell to achieve significant improvements in their production line efficiency.

The automated inspection system allowed Seat Martorell to achieve significant improvements in their production line efficiency.

• High Throughput: Thousands of blanks are processed daily, with each blank automatically inspected for missing bolts. The system identifies defects with high precision, even detecting up to 1% of blanks in some batches that were found to be defective.

• Reduced Downtime: By identifying and addressing missing bolts early in the process, the system drastically reduced production stops, allowing corrective actions to be taken upstream rather than at the final assembly stage.

• Improved OEE (Overall Equipment Efficiency): The system reduced downtime, improved the overall production flow, and led to fewer quality control issues, thus increasing the overall efficiency of the production line. • Labor Savings: The solution reduced the need for manual inspections, allowing human resources to be deployed only when necessary for rework, which led to a significant reduction in labor costs.

“The automated bolt inspection system has dramatically improved Seat Martorel’s production efficiency. By detecting missing bolts early in the process, they’ve minimized costly delays and rework, while boosting overall equipment efficiency and reducing labor costs. The integration of Gocator 3D sensors and RFID tracking has given them real-time traceability and data insights that support continuous process improvement.” — Iker Urgandarin, CEO, STT Systems

Next Steps

Moving forward, the automated bolt inspection system will continue to enhance the efficiency of Seat Martorell’s production line by:

• Preventing costly rework down the line by detecting missing bolts at the earliest possible stage. • Minimizing production stops and downtime, which in turn improves overall production capacity and OEE.

• Supporting continuous improvement efforts through robust data collection and analysis for preventive maintenance and process optimization. Scan showing 3D image of three bolts

The system’s scalability allows for future expansion, providing the ability to handle more complex inspections and adapt to new quality control needs

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product