CASE STUDY STT SYSTEMS and STEMMER IMAGING: AUTOMOTIVE BOLT INSPECTION SYSTEM WITH GOCATOR SMART 3D LASER PROFILERS

LMI Technologies, in partnership with STT Systems and Stemmer Imaging, implemented an automated quality inspection system to detect missing bolts on automotive blanks. The system integrated multiple Gocator 3D sensors and an RFID tracking system for real-time analysis.

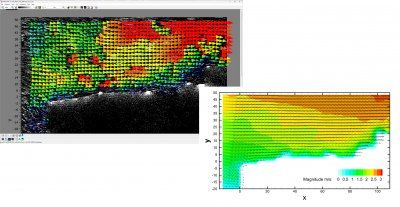

Only the changes count - Event-based cameras optimize flow analysis in science and industry

How does the air flow around an airplane? How does the blood move through our veins? And how can pollutant emissions in combustion processes be minimized?

Q&A with Cortona3D

Cortona3D is a well-established provider of technical documentation software. The flagship product of Cortona3D is RapidAuthor, an advanced authoring suite that enables companies to create professional and high-quality technical documentation with ease.

Intelligent Image Processing Supports Production Workers in Industrial 4.0 Applications

Automation plays a major role in Industry 4.0. Cost reduction, increased productivity and zero-defect quality are factors that are increasingly prompting companies to digitalize their processes. But often full automation also means high investments.

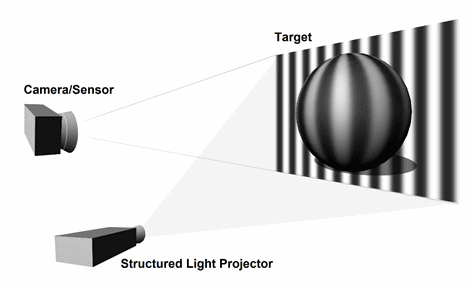

What is Structured Light Imaging?

Structured Light imaging is commonly used for machine vision because it can yield high resolution results. Some of the methods can be used effectively in moderate and high-speed applications.

Adaptive Automation

Using 3D data for the autonomous robot.

Toshiba Imaging Launches New Website with Camera Comparison Feature

The new Quick Reference Guide makes it easy to compare camera features, output formats and capabilities.

Records 1 to 7 of 7

Featured Product

Model TR1 Tru-Trac

The Model TR1 Tru-Trac® linear measurement solution is a versatile option for tracking velocity, position, or distance over a wide variety of surfaces. An integrated encoder, measuring wheel, and spring-loaded torsion arm in one, compact unit, the Model TR1 is easy to install. The spring-loaded torsion arm offers adjustable torsion load, allowing the Model TR1 to be mounted in almost any orientation - even upside-down. The threaded shaft on the pivot axis is field reversible, providing mounting access from either side. With operating speeds up to 3000 feet per minute, a wide variety of configuration options - including multiple wheel material options - and a housing made from a durable, conductive composite material that minimizes static buildup, the Model TR1 Tru-Trac® is the ideal solution for countless applications.

Robotics and Automation - Featured Company

Freudenberg Sealing Technologies

Freudenberg Sealing Technologies is a proven supplier for demanding products and applications, and a development and service partner to customers in the automotive industries and in general industries. We apply 175 years of engineering and materials expertise. Then and now - we are focused on serving our customers' requirements and needs. Starting with the development of the Simmerring® radial shaft seal in 1929, Freudenberg Sealing Technologies has continuously expanded its industrial seals and component portfolio to include a range of technology solutions that address critical issues like performance, power, friction, emissions and material compatibility.