ABB Robotics leads global effort to standardize measurement of industrial robot energy consumption

• ABB Robotics is leading the development of an International Standardization Organization (ISO) Technical Specification, alongside 11 other countries, to measure the energy consumption and efficiency of an industrial robot

• The new method will promote transparency, allow end users to make more informed decisions, and support the robotics industry to track and reduce the carbon footprint related to robot electricity usage

Robotiq Launches Tactile Fingertips for 2F Grippers, Bringing the Sense of Touch to Physical AI

Combining adaptive gripping with high-frequency tactile sensing enables robots to generalize across objects, tasks and environments without the cost and complexity of anthropomorphic hands.

Kollmorgen advances linear motor safety and performance with SafeMotion™ Monitor firmware upgrade

Integrated into AKD2G servo drives and the Kollmorgen 2G Motion System, SMM 3.0 continues to work with all motors that feature any HIPERFACE DSL® rotary-safe feedback system. It also allows the AKD2G drive to now support EnDat 2.2 safe feedback systems to better serve the growing demand for high-performance safety solutions in precision motion control.

FORT Robotics Launches Wireless E-Stop Pro: Real-Time Wireless Safety for Complex Industrial Environments

Designed to unlock robotic productivity in warehousing, manufacturing, and construction, the new Pro model provides the fail-safe control necessary for large-scale autonomous operations

Pickit 3D launches major release of its 3D robot vision solution

Simpler, more powerful and more resilient

Aerospace's Automation Breakthrough: How Robotics and AI Orchestration Are Rewriting the Supply Chain

For aerospace, the next leap will come from integrating physical automation with AI systems capable of coordinating the flow of information across complex, multi-vendor, secure environments that protect confidential information all while transforming efficiency..

Electric Linear Actuators For Automated Handling Equipment

Improve industrial warehouses with TiMOTION electric lifting systems. Actuators for intelligent material handling equipment enable the automation and optimization of logistics flows. Compact and easy to install, they are maintenance-free and durable.

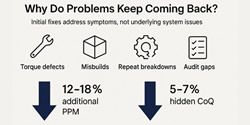

KPI Growth has an enemy called "Recurrence" - Fight it with Standard Work to Sustain the Growth.

Continuous Improvement is often misunderstood as an engine for solving more problems. In reality, the defining capability of a mature operation is ensuring the same problems never return.

IDS introduces a voluntary 3-year manufacturer's warranty across all industrial camera series

Maximum security and long-term investment protection for machine vision projects

Unbox Robotics Secures US$28 million in Series B Fundraise Led by ICICI Venture

-The company to use the funds to strengthen leadership & engineering teams, accelerate product development and expand market presence in India & globally

-The company also created meaningful liquidity for employees through its ESOP program as part of the transaction

PI Introduces Miniaturized Alignment Engine Platform for Scalable, Parallel E/O Wafer-Level Test

Parallel piezo aligners with fly height sensors enable faster PIC wafer testing.

igus 238 chainflex® cables certified for use in dry cleanrooms

In lithium-ion battery manufacturing, production purity is critical. Dust, particles, and moisture can compromise quality and shorten product life. Dry cleanrooms—where relative humidity is typically below one percent or just a few ppm—protect sensitive materials like electrolytes from chemical reactions. However, many machine components fail under such harsh conditions.

Event in Dallas, Targeting Manufacturing Labor Shortages Facing North Texas

The free, in-person event is designed for manufacturers in sectors such as metal fabrication, CNC machining, electronics, aerospace, food & beverage, and industrial equipment manufacturing — industries that form the backbone of the DFW manufacturing economy and are among the hardest hit by ongoing labor shortages.

OnLogic Launches Ultra-Compact CL260 Industrial PC for Edge Computing at Scale

The new palm-sized industrial computer delivers unmatched value, fanless dependability, and seamless integration in a tiny footprint for critical data gateway applications.

Unbox Robotics Secures US$28 million in Series B Fundraise Led by ICICI Venture

-The company to use the funds to strengthen leadership & engineering teams, accelerate product development and expand market presence in India & globally

-The company also created meaningful liquidity for employees through its ESOP program as part of the transaction

Records 1 to 15 of 7734

Factory Automation - Featured Product

3D Vision: Ensenso B now also available as a mono version!

This compact 3D camera series combines a very short working distance, a large field of view and a high depth of field - perfect for bin picking applications. With its ability to capture multiple objects over a large area, it can help robots empty containers more efficiently. Now available from IDS Imaging Development Systems. In the color version of the Ensenso B, the stereo system is equipped with two RGB image sensors. This saves additional sensors and reduces installation space and hardware costs. Now, you can also choose your model to be equipped with two 5 MP mono sensors, achieving impressively high spatial precision. With enhanced sharpness and accuracy, you can tackle applications where absolute precision is essential. The great strength of the Ensenso B lies in the very precise detection of objects at close range. It offers a wide field of view and an impressively high depth of field. This means that the area in which an object is in focus is unusually large. At a distance of 30 centimetres between the camera and the object, the Z-accuracy is approx. 0.1 millimetres. The maximum working distance is 2 meters. This 3D camera series complies with protection class IP65/67 and is ideal for use in industrial environments.

Robotics and Automation - Featured Company

Boston Dynamics

Boston Dynamics is the global leader in developing and deploying highly mobile robots capable of tackling industry's toughest challenges.