LG to develop smart shopping cart robot with E-mart

The South Korean tech giant said the robot will be developed by its research lab, which has been releasing various robots under the CLOi brand.

Mobile Robotics: Thinking in Terms of Fleet Productivity Is Key to Success

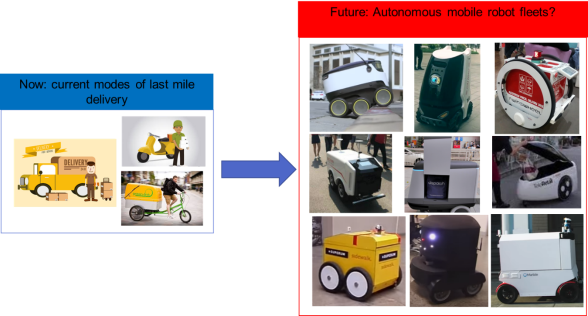

In this article, we will explore the basis and the future implications of this major transition. We will focus on two applications in particular: agriculture and last mile delivery.

What should warehouse and logistics companies be looking for when implementing robots?

Warehouses should be thinking about safety, simplicity and software.

Records 1 to 3 of 3

Featured Product

MVTec MERLIC 5.8

With MERLIC 5.8, MVTec expands its easy-to-use machine vision software. The latest version improves process reliability beyond pure image processing, offering enhanced error handling and optimized configuration. This enables faster setup and stable deployment across diverse production environments. Explore MERLIC 5.8 now

Robotics and Automation - Featured Company

PDS / Precision Drive Systems

Over 40,000 Spindles Repaired or Rebuilt Since 1996. PDS is a global leader in spindle repairs and retrofits for precision metal and robotics applications. With over 40,000 spindles repaired to better than-new-condition. PDS also offers new spindles, CNC accessories, and Industry 4.0 spindle monitoring. With offices in Bessemer City, NC (near Charlotte) and Herford, Germany PDS backs superb craftsmanship with a standard 12 month warranty on repaired spindles and an optional, industry-leading 24 month PrecisionCare warranty.