The Future of Autonomous and Wireless Charging

The real driver of change has been the need to reduce manual intervention and lower operational costs. When a robot can charge itself safely and autonomously, maintenance downtime drops dramatically, and so does total cost of ownership.

Automation's Future in Sustainable Transportation

From an operational standpoint, the role of robotics and automation in battery swapping is pivotal. Automated guided mechanisms handle each module, reducing labor costs and minimizing human error.

MHP study proves it: Wireless charging increases productivity of AGVs by 50%

The aim of the MHP study was to demonstrate the advantages of process-integrated charging points using inductive point charging systems such as Wiferion over conventional charging zones using a real-life optimization scenario in a medium-sized production company.

Propelling Your Operations Forward with Wireless Charging: Here's What to Know

Your charging strategy is a vital component for simplifying internal material transportation and data transfer. One option in the space gaining popularity and adoption is a wireless charging system, which provides intervention-free charging.

2022 Top Article - Wireless Charging Enables Industry 4.0 Implementation with Mobile Robots

The latest wireless charging solutions use techniques based on the principle of electromagnetic induction. When an alternating current is passed through an induction coil on the transmitter side, an oscillating magnetic field is created.

Wireless Charging to Bring 'True Autonomy' to Mobility Era in Robotics

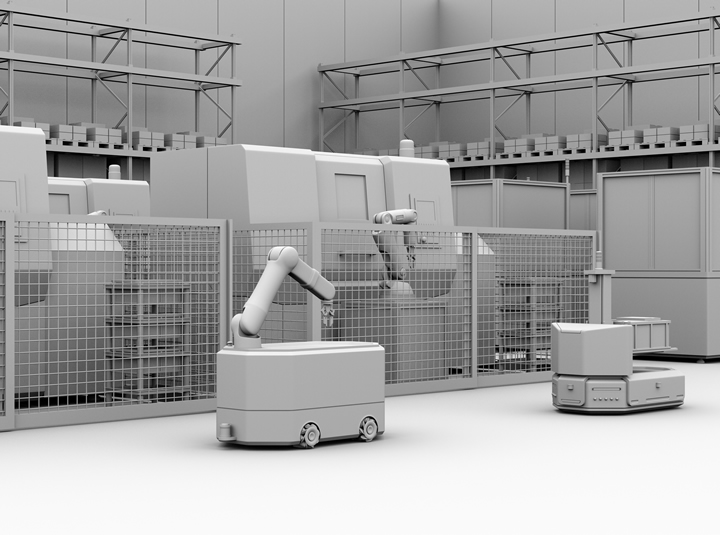

Imagine a factory floor with fast wireless charging pads or stations that doesn't require a human operator to make a physical connection and placed strategically around a facility to enable maximum uptime.

Records 1 to 6 of 6

Featured Product

IP Seals for Robots

Freudenberg Sealing Technologies' IPRS (Ingress Protection Seals for Robots) provides reliable protection for robotic systems operating in harsh environments. Designed to prevent dust, moisture, chemicals, and wear from compromising performance, IPRS extends service life and reduces maintenance. The adaptive Z-shaped geometry ensures sealing integrity under continuous motion, making it ideal for high-speed automation and outdoor applications. Manufactured with high-performance elastomers such as Fluoroprene XP and EPDM, IPRS offers exceptional resistance to lubricants, cleaning agents, and extreme temperatures. This makes it the perfect solution for six-axis robots, SCARA robots, AMRs, AGVs, and cobots.

With its low-friction design and durable materials, IPRS enhances energy efficiency and operational reliability in industrial and autonomous robotics. Learn more about our IPRS Seals

Robotics and Automation - Featured Company

Palladyne AI Corp.

Welcome to Palladyne AI, where we unleash the power of robotics with our revolutionary AI software platform for the physical world. In a world where robots are progressing toward human-like adaptability, seamlessly navigating dynamic environments and conquering complex tasks with unparalleled efficiency, Palladyne AI stands as the beacon of innovation toward that future reality. Through our cutting-edge artificial intelligence (AI) software platform, we are redefining the boundaries of robotics. Our goal is simple: Help companies with autonomy in their robotics operations by addressing key challenges of traditional robotic deployments.