Clamping applications often rely on sensors to detect whether the jaws or grippers are in the proper position - open or closed. Though other technologies can be used in place of sensors to determine the open/closed conditions, sensor implementation can increase reliability and obtain data that only a detection device very near the application can provide.

Contributed by | TURCK Inc.

Clamping applications often rely on sensors to detect whether the jaws or grippers are in the proper position – open or closed. Though other technologies can be used in place of sensors to determine the open/closed conditions, sensor implementation can increase reliability and obtain data that only a detection device very near the application can provide.

Applications of this nature are often found in robotic environments, commonly in the automotive industry, where robotic arms are used, among other things, to move large parts, weld parts together or hold parts in place. In order for this to occur, the arms are programmed to grip different objects per application. Proximity sensors in these applications are used to ensure the part is in place or the position of the grippers. A fault in this system that makes it unable to detect the proper orientation of the clamps can cause damage and downtime.

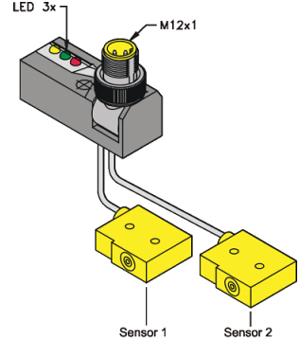

One way sensors are used in these applications is by placing sensors near the cylinder on the arm mechanism (of the robot) to detect the piston’s movement within the cylinder corresponding to the angle the jaws/ grippers open. This method can be conï¬ gured so the gripper is allowed to open to a precise position in relation to a speciï¬ c part. A drawback to this method is that the gripper cannot sense whether the actual part is in the gripper or if the location where this part being moved is in the proper position.

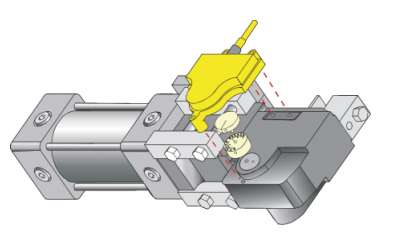

Another sensing method manufacturer’s use in clamping applications has the ability to detect part in place and/or whether the object (part) is in the grippers. This is done by placing a sensor into a groove within the actual gripper/jaw. By doing this, the sensor is able to detect whether the part is physically in the gripper/jaw, the clamp is in the right position, or the part is being moved to the proper location. The sensors are essentially custom embedded in the gripper/jaw so the part and the sensor are not damaged during this process. Though this is not a widely used method, it may prove effective in applications where a robot is performing multiple operations and part-in-place applications.

Placing a sensor into the physical jaw/gripper does not affect the open/closed function, rather this sensor technique is used in addition to cylinder position sensors and/or pressure monitors that gage whether the gripper/jaw is open. Implementing these sensing methods provides an increased measure of assurance that processes are functioning properly, and can lessen downtime caused by a sensing error in the clamp position.

TURCK Inc.

Turck is a leading manufacturer in industrial automation. With an enormously versatile range of more than 13,000 sensor, fieldbus, interface and connectivity products, Turck offers highly efficient product solutions for factory and process automation.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product