Booth #7963 - Zimmer Group will be exhibiting our latest developments in HRC (Human Robot Collaborative) grippers designed for most collaborative robots.

Contributed by | Zimmer Group

Tell us about your company.

Zimmer Group is a family-owned, German manufacturer of precision-quality components in six major technologies: Handling technology, Damping technology, Linear technology, Process technology, machine tooling and system technology. More than 30 years of experience and innovation makes it one of the leading manufacturers and providers of high-precision industrial components offering sales, service, and support throughout the United States and Mexico. Zimmer Group is among the leading manufacturers in the automation industry providing grippers, tool changers, crash protection, axis compensation, robot accessories and also complete end of arm turnkey gripper systems. As part of our motion control lineup, we manufacture shock absorbers, clamps and brakes for linear rail, and profile dampers.

Your company will be exhibiting at AUTOMATE, what is it that makes this an important event for your company?

The AUTOMATE exhibition has in the past proven be one of the best robotic automation shows in North America. Zimmer Group specializes in end-of-arm tooling and robotic accessories, so it is absolutely a show that we need to exhibit in.

What makes your booth a must visit for AUTOMATE Attendees?

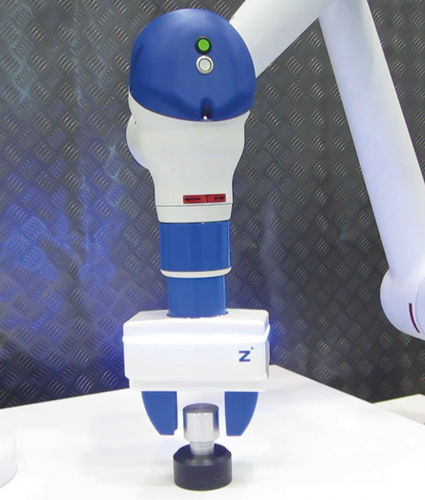

At AUTOMATE 2019, Zimmer Group will be exhibiting our latest developments in HRC (Human Robot Collaborative) grippers designed for most collaborative robots.

.jpg)

Additionally, we will have our cost effective GEP2000 series electric grippers on display, which boast the best power-to-weight-to-cost ratio in the industry. We will also show a lower cost aluminum guided version of the industry best 5000 series grippers.

AUTOMATE has many educational sessions, forums & Demo’s, is your company involved in any of them this year?

We will be demonstrating several robotic application including collaborative applications.

When you get a chance to walk the exhibit hall floor yourself, what is it you will be most interested to see? Any educational sessions, pavilions etc. you plan on attending?

Our goal when we walk the floor is to see all the latest developments in robotic automation and end-of-arm tooling.

The factory floor is undertaking rapid advancements, be it automation, robotics, machine vision or data. Automation Technology is a huge part for many manufacturers, give us an idea on how your company and product is being utilized now in the smart factory.

Zimmer Group was a pioneer in integrating IO-Link technology into grippers and end-of-arm tooling. IO-Link is one of the leading standards in IoT and Industry 4.0 smart manufacturing. We are also heavily invested in Virtual Manufacturing Simulations and Digital Twins.

Give us your thoughts on what the future holds for manufacturers and automation technology.

The automation industry will become smarter and more flexible. Thru use of IO-Link and IoT, small batch production runs will become more efficient, cost effective and commonplace

If you would like please provide contact information for a reader to setup a booth demo.

To setup an appointment for a booth demo or visit please contact Costas Charalambous at costas.charalambous@zimmer-group.com or +1 631 897 8366

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Zimmer Group US, Inc.

Are you interested in premium products in the fields of mechanical and plant engineering? Do you want to learn more about our solutions in the fields of automation, damping, linear, processing, tooling, and machine tooling technology?

Other Articles

Automate 2025 Q&A with Zimmer Group

Converting Passenger Aircraft to Freight Aircraft - the Zimmer Group Is on Board!

Automated Loading and Unloading of CNC Machines

More about Zimmer Group US, Inc.

Featured Product