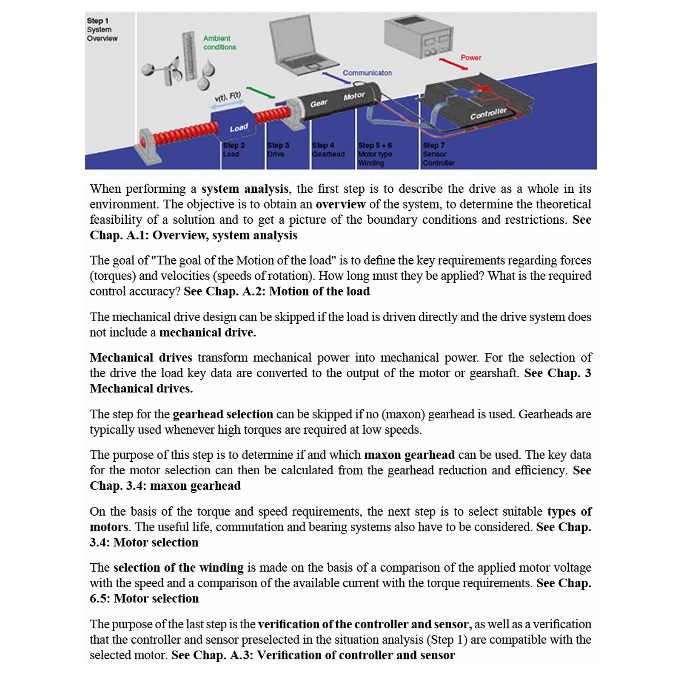

The extensive collection with illustrations and descriptions includes formulas, terminology and explanations of the calculations that are relevant for drive systems. A flow chart provides assistance in selecting the right drive for each purpose.

maxon motor - Formulae Handbook for Design Engineers

maxon motor - Formulae Handbook for Design Engineers

Contributed by | maxon motor

Knowledge of drive technology and motion control.

maxon academy provides extensive knowledge of drive technology and motion control. Learn more about the interaction of motor, gearhead, sensors, and controller.

Formulae Handbook Preview:

Order the maxon motor Formulae Handbook for Design Engineers

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

maxon group

maxon is a leading supplier of high-precision DC brush and brushless servo motors and drives. These motors range in size from 4 - 90 mm and are available up to 500 watts. We combine electric motors, gears and DC motor controls into high-precision, intelligent drive systems that can be custom-made to fit the specific needs of customer applications.

Other Articles

Multi-axis motion control drives pipe-based robots

Automate 2025 Q&A with maxon group

Understanding Torque and Speed in Electric Motors

More about maxon group

Featured Product

.jpg)