To manage growth in eCommerce and its associated challenges retail companies will need to embrace automation. Smart logistics provider Geek+ and market research firm Interact Analysis cooperated to create a whitepaper to discuss the future for smart logistics automation.

The Future of Smart Logistics Automation

The Future of Smart Logistics Automation

Q&A with Hong Yu, Chief Marketing Officer at smart logistics provider Geek+ | Ash Sharma, Senior Research Director at market research firm Interact Analysis

Q&A with Hong Yu, Chief Marketing Officer at smart logistics provider Geek+; and Ash Sharma, Senior Research Director at market research firm Interact Analysis

RoboticsTomorrow: Can you give us the background to Geek+ - how did the company start?

Hong Yu: It all started in 2015, when our founding team, led by our CEO Yong Zheng, decided to team up and combine their knowledge as software engineers and robotics developers to create new technologies that would enable change and solve actual problems. It’s no news that the supply chain and logistics sector have been under strain for many years, and having understood that, I believe they saw a worthy challenge. To create comprehensive systems using robotics, software, and AI that can help solve industry bottlenecks and realize an intelligent transformation of the supply chain.

RoboticsTomorrow: Can you explain your warehouse automation technology for our readers?

Hong Yu: Simply put, our intelligent robotics solutions can streamline operations by automating many of the time-consuming and redundant tasks that are often done manually. Instead of having warehouse employees spend hours on walking long distances to find ordered goods, we let robots bring the goods to them at workstations. The robots are controlled by a Robot Management System (RMS) that uses intelligent scheduling and task distribution that allows the robot to autonomously travel the most optimal route between the shelf of the ordered goods and the workstation. It’s a more efficient and organized way of arranging warehouse operations that allow employees to focus on more value-added tasks. One of the issues of warehouses using traditional systems built on fixed infrastructure is that it’s difficult to adjust operations should there be a change in demand or a need to scale up. But when it comes to autonomous mobile robots, there’s no need for fixed guidance systems on warehouse floors (other than simple QR code stickers), making it a lot easier to implement as robots and shelving racks are deliverable to almost any location at short notice. And, if a business is suddenly faced with higher throughput demand, all one has to do is adjust the number of robots, workstations, and added hours to the day. This makes our warehouse automation technology a very flexible alternative.

RoboticsTomorrow: What were the specific benefits Decathlon enjoyed as a result of working with Geek+?

Hong Yu: We started the cooperation with Decathlon in 2018 and after having worked together for more than two years, I believe some benefits were evident from the start while others were gained over time. For example, shortly after the very first deployment, Decathlon saw the average productivity of labor triple, its storage capacity increase by 40%, and massively reduced shrinkage levels. The fact that our system was able to integrate Decathlon’s RFID technology was also an important part. It was thanks to all of the above-mentioned benefits that they decided to continue to work with us and scale their operations. The automated robotics system also proved to be very beneficial earlier this year, when the prevalence of Covid-19 and quarantine rules meant an increase in their e-commerce business while most of their warehouse employees were unable to come back to work. With the support from our system, Decathlon was able to achieve full 24/7 automated operations in one of its shanghai warehouses. And, in order to deal with the increase in online sales, we helped them flexibly relocate robots from its retail warehouse to its e-commerce warehouse. In turn, Decathlon, unlike many others, was able to secure business continuity.

RoboticsTomorrow: Technology scalability is something I’ve read your comments on before. Can you tell us a bit about how Geek+ achieves this, and how it helped in the specific Decathlon case?

Hong Yu: Yes, as markets and industries grow more uncertain it’s getting increasingly difficult to make forecasts for longer time periods. And as I mentioned, if you have a system reliant on fixed heavy infrastructure it’s not that easy to scale operations. Not only is it expensive to rebuild or adjust fixed infrastructure, but it’s also time-consuming and may lead to a slow ROI. Scalability means that our system allows Decathlon to flexibly scale operations in line with growth demands, both over a longer timeframe and for peak periods. Investment flexibility means that Geek+ can lease robots to companies over temporary periods, this is particularly useful for big e-commerce events or other temporary demand peaks. As mentioned, this turned out to be very beneficial to Decathlon under covid-19 as it allowed them to quickly adjust to a heightened demand in e-commerce sales and secure business continuity. In turn, the ability to meet underlying growth demands both over longer and shorter timeframes has allowed Decathlon to achieve a 1-3 year ROI.

RoboticsTomorrow: Can you explain the potential growth in warehouse automation, based on your research, as you see it?

Ash Sharma: To manage growth in eCommerce and its associated challenges (in particular, complex networks of distribution channels, high levels of competition, and labour shortages) retail companies will need to embrace automation. When it comes specifically to mobile robots, we think the internet shopping boom has bought penetration forward five years overnight, and what companies were planning for 2024-2025 is happening now due to the coronavirus. But it’s wider than just mobile robots: as companies realise they need to be less reliant on human labour, and that they need to make manufacturing and warehousing more resilient and efficient, all types of warehouse automation will grow.

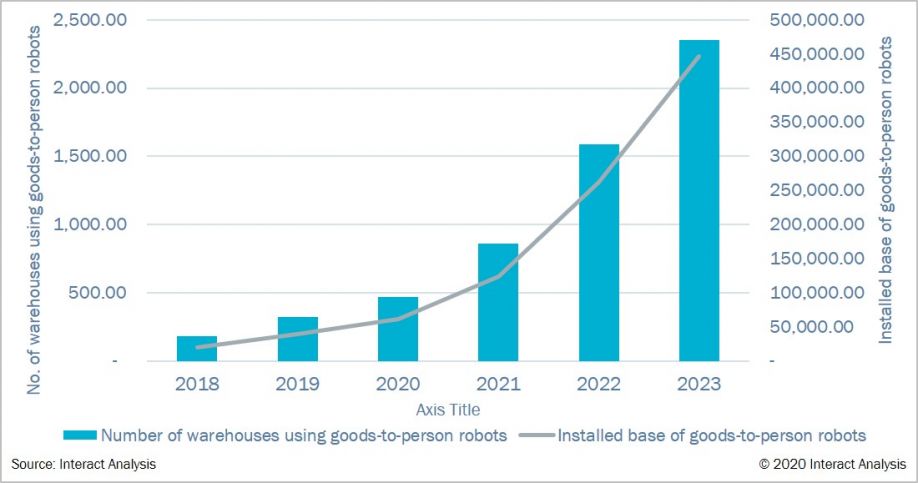

There are close to 100,000 distribution and fulfilment centers around the world. Today fewer than 5% of those are fully automated. Amazon aside, goods-to-person robotics have only been implemented in a few hundred warehouses so far, but we expect that to change massively in the next five years and the potential is huge.

RoboticsTomorrow: What about the COVID-factor - how exactly do you see it impacting eCommerce – in the longer term?

Ash Sharma: We are confident that coronavirus will have a long-term impact on the future of eCommerce. Our data shows that eCommerce got a major short-term boost almost everywhere that went into lockdown. But our prediction goes beyond this to argue that many people will switch to online shopping in the crisis, and then stick with it forever. Retailers will face multiple challenges – such as improving efficiency of online marketing and sales practices, as well as offering new products – in particular items purchased mainly by the elderly – who have traditionally been ignored by online sellers.

Elderly people are particularly relevant in this story as they represent a large demographic who have not traditionally used eCommerce at all. They are now converting in droves, and it is unlikely they will switch back when this is over.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product