OMRON Introduces the OL-450S - A Complete Autonomous Mobile Robot Solution for Material Handling

Featuring an integrated lifting plate, advanced navigation, and centralized fleet management, the OL-450S offers a complete solution for automating material transport in automotive, semiconductor and electronics, food and household goods, and other fast-paced industries.

Automating Industrial Inspection With Autonomous Mobile Robots

Through regular and thorough inspections, faults, wear and tear, and defects can be detected at an early stage and proactively acted upon, thus preventing production downtimes.

Invata Rolls Out New Line of Mobile Robotics

The INVATABOTICS fleet will provide enhanced automation processing capabilities to Invata customers in the areas of order fulfillment, returns processing, mobile storage and retrieval, sortation and transportation, and pallet, case, tote, and unit picking.

NVIDIA Builds Isaac AMR Platform to Aid $10 Trillion Logistics Industry

DeepMap, Metropolis, and ReOpt improve performance for fleets of autonomous mobile robots amid expectations for nearly 6x increase in robot sites by 2025.

True Flexibility in your Robotics System

Leveraging third-party hardware, such as a robotic picking arm, and software, such as customized WMS, is crucial if you want true flexibility in your robotics system.

Important Considerations When Implementing AMR Solutions

When implementing mobile robotics solutions in a facility, it's important to consider strategies for ensuring stability, seamless interaction with people, accurate detection of obstacles, and set up a successful emergency evacuation plan.

Robust Drive System Simplifies Mobile Robot Development for the Factory of the Future

Another issue is the inability of some AGVs and AMRs to drive smoothly while operating slowly, an important consideration for scenarios where the AGV or AMR itself may perform part or component assembly.

10 Factors Warehouse Managers Should Consider for Goods-to-Person Fulfilment

In this article, let's dive deeper into how it works and what factors you should consider if you are thinking to switch to using the Goods-to-Person fulfillment model.

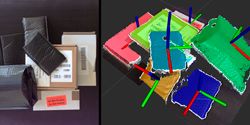

Vision Guided Robotics & Artificial Intelligence: An Explanation for the Non-Technical

If you are an investor, business leader, or technology user who seeks to understand the technologies you are investing in, this article is for you. What follows is an explanation of vision-guided robotics and deep-learning algorithms.

Increasing Warehouse Efficiency with Robotics

Through the combination of technology and our expertise in designing automated high-density storage and retrieval, we're able to achieve high levels of throughput that only automation working alongside people can bring.

Zebra To Acquire Fetch Robotics - Our Analysis

On July 1st Zebra Technologies announced that it would be acquiring Fetch Robotics. It will be paying $290 million to acquire the 95% of the company that it does not already own, in a deal that values Fetch Robotics at $305 million.

5 MIR1000 Robots Automates the Internal Transportation of Heavy Loads at Florisa

Five autonomous mobile robots (AMR) MiR1000 have improved productivity, safety and eliminated storage problems within the Florisa plant, a company that operates in the textile segment, with production focused on the dyeing of natural and artificial fibers.

Upcoming WindRiver Webinar - ROBOTICS: THE ERA OF AI AND AUTONOMY

In this webinar we will look at how integrating robotics into the working world means that both cobots and autonomous systems will be important differentiators for production, processes, and innovation.

AGV Robotization: The Solution

Businesses which have invested in robotics quickly realize the impact of increased productivity and continue investing. There is no "turn back syndrome" for these solutions; the increases in competitiveness and quality push businesses to adopt a continuous robotics policy.

Warehouses Turn to Automation to Meet Permanent Peak Demand

Supply chains are relying on automation to effectively adapt to fluctuating demand levels, new safety protocols, and shrinking labor pools. The need to operate efficiently, safely, and productively with less people is critical for today and also for success in the future.

Records 1 to 15 of 49

Featured Product

3D Vision: Ensenso B now also available as a mono version!

This compact 3D camera series combines a very short working distance, a large field of view and a high depth of field - perfect for bin picking applications. With its ability to capture multiple objects over a large area, it can help robots empty containers more efficiently. Now available from IDS Imaging Development Systems. In the color version of the Ensenso B, the stereo system is equipped with two RGB image sensors. This saves additional sensors and reduces installation space and hardware costs. Now, you can also choose your model to be equipped with two 5 MP mono sensors, achieving impressively high spatial precision. With enhanced sharpness and accuracy, you can tackle applications where absolute precision is essential. The great strength of the Ensenso B lies in the very precise detection of objects at close range. It offers a wide field of view and an impressively high depth of field. This means that the area in which an object is in focus is unusually large. At a distance of 30 centimetres between the camera and the object, the Z-accuracy is approx. 0.1 millimetres. The maximum working distance is 2 meters. This 3D camera series complies with protection class IP65/67 and is ideal for use in industrial environments.

Robotics and Automation - Featured Company

MMP Inc. / MIDWEST MOTION PRODUCTS, INC.

The Leader in Rapid Prototyping of High-Quality Motion Control Solutions. MMP is actively engaged in the design, manufacturing and distribution of standard and custom motion control equipment, including fully reversible brushed and brushless DC gearmotors, motors with failsafe brakes and servomotors with feedback devices such as analog tachometers and encoders. We also provide fully-sealed IP-65 motor speed controls @ 12/24/48 VDC, AC~DC power supplies and a wide variety of 12/24 VDC linear actuators. If you need a sample right away, we can be a project saving convenience for you. We provide more than 8000+ released DC Gearmotor designs with cost-effective solutions for robotics and automation companies. These designs are unique and custom-built to suit the specific application requirements of the motion control projects.

.jpg)

.jpg)