Know What To Consider When Selecting The Proper Gripper

Though often overlooked, grippers are a significant cog in a successful automation system and choosing the proper one can result in optimized performance, uptime and operator safety.

Choose Your Cobot Vacuum Gripper Wisely

Plug-and-play cobots offer a perfect transition from manual handling or assembly to more automated operations. But, it is important to choose one with a powerful and safe grip!

IMTS Preview with ATI Industrial Automation

Booth #236417 - ATI will present three new products at the 2018 show. You may have heard about the Axia80; ATIs high-performance, low-cost force/torque sensor, but this year attendees can see it live in an interactive demonstration.

This Robot Has Soft Hands. It Could Be the Future of Sustainable Production

Traditional robots have been designed to perform a single task extremely efficiently. But when the item or the task changes, which is often the case with food, these traditional machines need to be reintegrated and reprogrammed

Electric Grippers

Applications in which the environmental/atmospheric conditions are controlled are usually applications where having a pneumatic gripper is undesirable. Clean room, medical, pharmaceutical applications, etc.

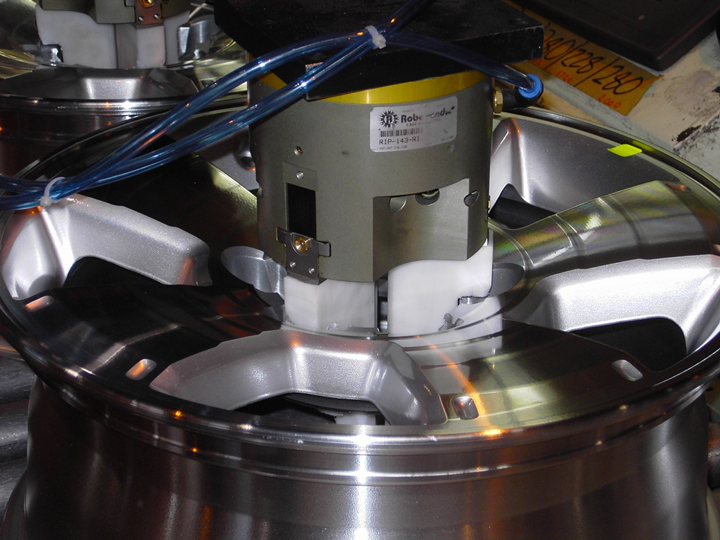

Genesis Systems Group Innovates NDI Systems with ATI End-Effectors

The NSpect family of Non-Destructive Inspection (NDI) Systems from Genesis Systems Group is making quite an impression. By combining ATI End Effectors, KUKA Robots, and vast engineering expertise, Genesis creates more efficient methods of NDI that encourage safety and increase quality. Genesis customers have confidence in NSpect Products as well-the company has integrated more than 30 NSpect Systems in the last five years.

Records 16 to 21 of 21

Featured Product

Palladyne IQ - Unlocking new frontiers for robotic performance.

Palladyne IQ is a closed-loop autonomy software that uses artificial intelligence (AI) and machine learning (ML) technologies to provide human-like reasoning capabilities for industrial robots and collaborative robots (cobots). By enabling robots to perceive variations or changes in the real-world environment and adapt to them dynamically, Palladyne IQ helps make robots smarter today and ready to handle jobs that have historically been too complex to automate.

Robotics and Automation - Featured Company

CMES Robotics Inc.

Powered by AI, CMES Robotics enables 3D vision for factory robots. CMES AI vision software enables robots to recognize unstructured, flexible, or deformed objects, pick them up, and loading and unloading. CMES Vision software has been deployed worldwide for random palletization and depalletization along with void filling applications. CMES Robotics automates your warehouse, logistics, and supply chain.