7Bot: $300 6-axis Aluminum Desktop Robot Arm

From 7Bot's Kickstarter campaign:

In 2014, two of us co-founded project uArm with other two makers. There we received a lot of feedback from our Angel backers:

More axis for more powerful applications, and more controlling dimensions (force control, speed control and flexible-joint).

More rugged material rather than Acrylic, muscular servos hardly to be burned out.

More intelligent API. Better inverse kinematics and path planning algorithms to make the movement more precise and smooth.

More accessories and various of end-effectors.

Our custom servos with precise position feedback allow you to quickly set it up and operate in teaching mode without any codes. In this mode, you can simply drag each joint of the robot to a serious of desired way points. The movements will be recorded, and could be replayed in an optimized path.

A multi-platform supported 3D visualization application will be provided for you to manipulate the 7Bot Arm intuitively. With our 3D visualization application, you can easily set and read the position of each joint separately with real-time graphic interface.

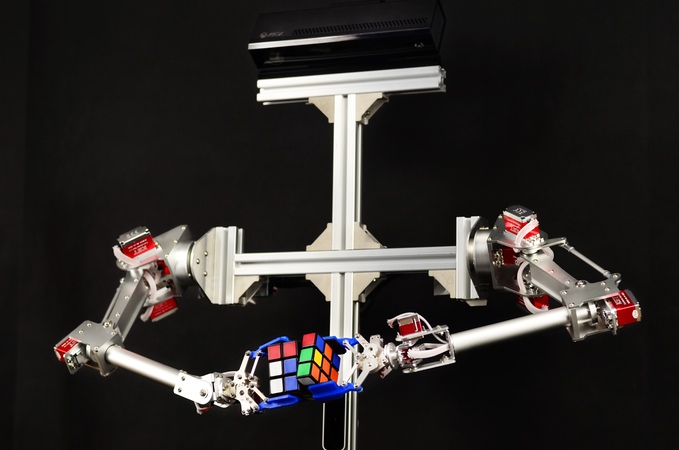

If you have two 7Bot Arms, you can build this amazing Humanoid robot -7Bot Arm Dual:

Estimated shipping date is January 2015... (7Bot's Kickstarter campaign)

Records 1 to 1 of 1

Featured Product

Model TR1 Tru-Trac

The Model TR1 Tru-Trac® linear measurement solution is a versatile option for tracking velocity, position, or distance over a wide variety of surfaces. An integrated encoder, measuring wheel, and spring-loaded torsion arm in one, compact unit, the Model TR1 is easy to install. The spring-loaded torsion arm offers adjustable torsion load, allowing the Model TR1 to be mounted in almost any orientation - even upside-down. The threaded shaft on the pivot axis is field reversible, providing mounting access from either side. With operating speeds up to 3000 feet per minute, a wide variety of configuration options - including multiple wheel material options - and a housing made from a durable, conductive composite material that minimizes static buildup, the Model TR1 Tru-Trac® is the ideal solution for countless applications.

Robotics and Automation - Featured Company

maxon group

maxon is a leading supplier of high-precision DC brush and brushless servo motors and drives. These motors range in size from 4 - 90 mm and are available up to 500 watts. We combine electric motors, gears and DC motor controls into high-precision, intelligent drive systems that can be custom-made to fit the specific needs of customer applications.