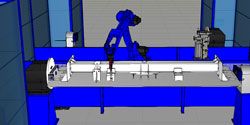

Robotecki Redefines Robotics Precision Cutting and Drilling Applications with RoboDK

With their application, the team at Robotecki not only reduced labor-dependency for these key tasks, they improved the quality of production and throughput.

Robotic programming brings increased productivity and faster return on investment

"By optimizing robot programs, users can see a significant increase in productivity while generating more profit with their robot, using robots for short production runs, and delivering closest conformance to design." Carlos Marcovici, Robotmaster Authorized Partner, Brazil

10 things to consider when exploring Offline Robot Programming software solutions

Offline Robot Programming (OLP) takes the programming "offline" - away from the teach pendent / robot cell - allowing the user to generate the robotic code from their computer without having to take the robot out of production to generate it.

How to Successfully Automate Packaging in Low-volume, High-mix Production

Recent advances in robotic programming have reduced the implementation time of robotic automation to a point where even small and medium sized manufacturers with high-mix, low-volume production can get a robotic packaging application up and running in just a few hours

Have You Looked at Automating Fabrication Tasks in the Past? Why Didn't You?

We recently hosted a webinar titled: Unlock Value-Stream Productivity with Robotic Cutting. During this webinar, we polled audience members. Our first question: Have you looked at automating fabrication tasks in the past. Most respondents said yes.

Big Trends in Offline Programming Software for Robot

In the world of robotics, Offline Programming (OLP) has come a long way in a short time, and the global pandemic has jumpstarted more innovation. Industrial robots have evolved to collaborative robots ("cobots") that work side by side with their human counterparts.

Offline Robot Programming for Polishing Aircraft Engine Lipskins

In 2020, McStarlite invested in automation by integrating a KUKA robot coupled with Robotmaster offline robot programming (OLP) software, to perform the lipskin polishing application.

10 Things to Consider When Exploring Offline Robot Programming Software Solutions

Offline Robot Programming (OLP) takes the programming "offline" - away from the teach pendent / robot cell - allowing the user to generate the robotic code from their computer without having to take the robot out of production to generate it.

Calculating the ROI of Offline Robot Programming Software

Capital investments in advanced manufacturing environments require careful consideration, especially if that investment is for a new process or technology. If you are looking at"¯investing in OLP here are some things to consider about the potential return on investment (ROI).

Is your OLRP Implementation Process SMART?

For any Offline Robot Programming solution to be effective, the virtual robot cell set up in the software must be identical to the existing physical robot cell. OCTOPUZ refers to this process as "implementation".

Records 1 to 10 of 10

Featured Product

Zimmer Group - THE PREMIUM GRIPPER NOW WITH IO-LINK

IO-Link is the first standardized IO technology worldwide for communication from the control system to the lowest level of automation.

Robotics and Automation - Featured Company

Palladyne AI Corp.

Welcome to Palladyne AI, where we unleash the power of robotics with our revolutionary AI software platform for the physical world. In a world where robots are progressing toward human-like adaptability, seamlessly navigating dynamic environments and conquering complex tasks with unparalleled efficiency, Palladyne AI stands as the beacon of innovation toward that future reality. Through our cutting-edge artificial intelligence (AI) software platform, we are redefining the boundaries of robotics. Our goal is simple: Help companies with autonomy in their robotics operations by addressing key challenges of traditional robotic deployments.

.png)