Encoders make industrial robots accurate enough to perform positionally accurate machining and handling tasks on large components. Let's talk about how.

Why Rotary Encoders Might Be the Best Fit for Your Industrial Robotics Design

Article from | Heidenhain

Industrial robots are fast, powerful and durable. Unfortunately, when it comes to some tasks, they struggle to offer sufficient position accuracy. Consider any work that requires both a carefully positioned and guided tool center point and significant maneuverability. Such work necessitates multiple axes, which all require their own servo motors. Each servo motor opens up opportunities for zero position error, backlash and joint elasticities. Plus, the machining process may affect the rigidity of the robot’s mechanics, and therefore accuracy.

There are advanced calibration methods available, and they do help with repeatability. However, absolute position accuracy is lower by comparison (often worse by a factor of ten). This makes first-gen robots unsuitable for many applications (e.g., the aerospace industry). That’s where encoders come in. Every HEIDENHAIN and AMO encoder offers superior accuracy, whether it’s an ECA 4000 angle encoder or the AMO WMRA. But when it comes to industrial robotics, rotary encoders are often the best fit.

Benefits of Using Rotary Encoders for Robotic Applications

Encoders make industrial robots accurate enough to perform positionally accurate machining and handling tasks on large components. Let’s talk about how.

Position Sensing and Feedback

The better an encoder can process and communicate feedback, the more accurately it can communicate movement metrics and the actual position of the robot’s tool center point. But with that sensitivity comes a drawback: strong vibrations and electromagnetic interference can affect encoder performance. HEIDENHAIN inductive rotary encoders solve that problem. They’re robust, resistant to strong vibrations and their EnDat interface stands up to electromagnetic interference.

In addition, secondary rotary encoders, mounted after each gear train, capture a robot joint’s actual position, protecting against zero position error and backlash, and measuring retroactive forces. The result: absolute position accuracy improves by 70 to 80 percent. Modular rotary encoders use scale drum or tape and separate scanning units, which make them ideal for challenges unique to the hollow-shaft diameters and spatial constraints unique to many robots.

Velocity and Acceleration Control

By monitoring the rotation of a robot’s joints, rotary encoders provide high-quality monitoring of its velocity. Since operators can accurately adjust acceleration in real time based on this feedback, they have finer control over the robot’s movements. This keeps the work precise and repeatable, optimizes efficiency and results in a better end product.

Multi-Axis Coordination

Robot joints are fully interdependent, so the movements of each axis must be carefully controlled at all times in order to maintain precision and repeatability. The continuous feedback provided by a rotary encoder enables that control, regardless of how many axes upon which the robot operates (key in any situation, but especially with large components).

Common Types of Rotary Encoders Used in Robotics

Solid-Shaft Encoders

Shaft encoders measure the speed and position of rotating shafts by attaching a disc or wheel to the shaft being monitored and detecting its position with a stationary sensor. Every time the disc passes the sensor, it generates electrical signals that indicate the shaft’s position and speed. There are absolute shaft encoders, which provide a unique code for each shaft position and incremental shaft encoders, which use electronic pulses to measure speed and direction.

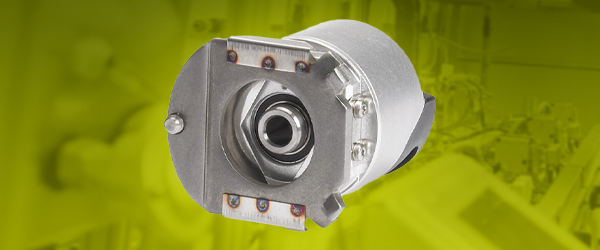

Hollow-Shaft Encoders

Hollow-shaft encoders do not have any separate couplings or adapters, greatly reducing size and simplifying system complexity. They feature a hollow bore or center opening, allowing the shaft to rotate inside the encoder housing. This makes them excellent in robots, where space is often limited. Plus, since the encoder is mounted directly on the shaft, there’s no slippage or backlash, making these an excellent choice for precise motion control.

Dual Encoders

Dual encoders such as HEIDENHAIN’s KCI 120 Dplus provide incredible accuracy by measuring the rotational position and speed of a common shaft simultaneously. One encoder measures the shaft’s absolute position, while the other encoder measures its relative position or angular displacement. Simultaneous measurement of two different axes of rotation provides better feedback, which in turn allows for more precise positioning and speed control.

General Criteria for Robotics

When choosing an encoder, before you even think about performance aspects, there are some general factors to consider:

Needs

What is the ultimate application of this robot? Whether it’s assembling aircraft fuselage or making precise cuts across large components, consider your robot’s needs when choosing an encoder.

Cost

Manufacturers must consider how much an encoder costs, and whether that encoder will truly add value in the long run. An encoder may have a higher price upfront, but lower costs elsewhere in the design process. What’s more, higher-cost encoders often give robotics manufacturers an edge in the market thanks to better functional safety, higher accuracy and fewer costs in the long run.

Operating Environment

The environment in which the robot works may determine just how robust an encoder needs to be or what kind of scanner would work best. Beyond the forces and vibrations an encoder must deal with during operation, there are also conditions like dust, temperature or humidity. Will the encoder need an enclosure? Will vibration reach over 30-40 Gs, likely requiring a magnetic scanner? Is it highly clean, allowing for a more accurate optical scanner? What’s perfect for one environment may be ill-suited for another.

Footprint

Robots generally offer limited space (especially when you need a secondary encoder). What might seem perfect for a manufacturer’s needs may turn out to be too big, so rotary encoders such as the KCI/KBI 1300 series—with their lower profiles and lack of bearing—can make all the difference.

Flexibility

In addition, consider the variants available. Every component in a robot can raise geometric constraints. It’s best to use rotary encoders versatile enough to fit these constraints or to have matchable variants. You can also look for modular models, or kits you assemble yourself—they may require more know-how during setup, but it can be very beneficial to tailor a robot exactly to your needs.

Assembly

Roughly 70 percent of production costs come up during the design phase before the robot is even active. Making changes to design or processes after operations commence costs even more. Therefore, easy-to-mount encoders can save a lot of time and money. The simpler the setup, the fewer work steps and hours of training necessary to build and install each robot.

Safety

Whatever the job, risk to human operators (and to robots themselves) must be kept to a minimum. Look for a dual encoder certified in accordance with Safety Integrity Levels (SIL) and Performance Levels (PL). Use an interface such as EnDat for simpler implementation of a complete system. This speeds up design time and minimizes error-related delays.

Performance Characteristics to Consider

Once you get past the basics, the actual mechanics and performance characteristics of the encoder come into play:

Quality Assurance

QA can be a time-consuming process, but some encoders can speed it up significantly. Some don’t need a calibration run and can operate as soon as they’re mounted—the encoder equivalent to “plug and play.” There are bearingless encoders with electronic mourning diagnostics that perform immediate safety checks to make sure they’re correctly installed. And some models feature electronic ID labels accessible through the interface and can store their own data, enabling automated setup.

Maintenance Posture

Manufacturers need machines that can deliver a lot of real-time data through a reliable interface. Any encoder should provide constant, precise measurements and deliver detailed condition data (such as error messages or warnings based on valuation numbers). This resulting diagnostic information can then be analyzed to anticipate needed maintenance or troubleshoot quickly. For even better operation, use an encoder with the EnDat 3 interface; it transfers data faster, requires fewer cables and monitors the temperature of everything from the robot arm to the inside of the cabinet.

Wide Tolerances

There are many risks inherent in robotics: zero point error in joints, reversal errors in gearboxes or load bearing issues due to material elasticity. These factors—known collectively as hysteresis—can cause serious issues during manufacturing. Temperature swings and aging components come into play, as well. The right encoder compensates for these effects.

Automation and robotics are growing more prevalent, across more industries, every year. In the constantly evolving, ever-more demanding automation market, your choice of encoder can take your robotics designs from good to next level. Make sure you consider all options and learn how to select the right one. Your operators and your bottom line will thank you for it!

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product