European researchers developed energy-efficient machine vision inspired by human eyesight and the brain

This enables, for instance, intelligent robots and drones that can operate independently in a rescue mission after an earthquake without constant network connections or bulky batteries.

2025 Top Article - The Ultimate Guide to Depth Perception and 3D Imaging Technologies

Depth perception helps mimic natural spatial awareness by determining how far or close objects are, which makes it invaluable for 3D imaging systems. Get expert insights on how depth perception works, the cues involved, as well as the various types of depth sensing cameras.

CASE STUDY STT SYSTEMS and STEMMER IMAGING: AUTOMOTIVE BOLT INSPECTION SYSTEM WITH GOCATOR SMART 3D LASER PROFILERS

LMI Technologies, in partnership with STT Systems and Stemmer Imaging, implemented an automated quality inspection system to detect missing bolts on automotive blanks. The system integrated multiple Gocator 3D sensors and an RFID tracking system for real-time analysis.

The Right 3D Vision Scanner for Robotic Programming: Laser Profilers vs Structured Light Scanners in Industrial Automation

By combining flexible vision technology with automated processing, manufacturers and system integrators can shorten deployment cycles, reduce reliance on fixtures, and achieve the adaptability needed for high-mix, high-precision production.

Automatic Visual Inspection: The Secret to Flawless Manufacturing Quality

By switching to a digital inspection framework, manufacturers aren't removing the human element; they are elevating it. Instead of spotting defects, engineers can focus on fixing the root cause.

How the Best Infrared Thermal Modules Enhance Machine Vision for OEMs

Infrared thermal modules convert temperature data into a visual, quantifiable format, enabling machine vision systems to detect defects, monitor conditions, and optimize processes based on thermal metrics.

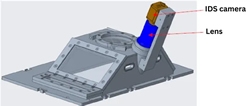

High-precision process monitoring and error detection in additive manufacturing

Powder bed-based laser melting of metals (PBF-LB/M) is a key technology in additive manufacturing that makes it possible to produce highly complex and high-performance metal components with customised material and functional properties.

Importance of Global Shutter Cameras for Industrial Automation Systems

Maintaining image clarity is a critical part of industrial automation. Not all sensors deliver the required consistency across different conditions. Learn how global shutter cameras help perform industrial automation tasks, their use cases, and must-have imaging features.

From Centralized Brains to Edge Intelligence: Rethinking Compute Architectures for Autonomous Mobile Robots

Today's AMRs are navigating unpredictable warehouse aisles, adapting to real-time sensor feedback, and running machine learning inference on the fly - meaning developers can ill afford inefficient systems.

Bumblebee X Powers Taiga Robotics' Mining Automation with AI-Driven Vision

Recently, Taiga Robotics tackled one of mining's most challenging problems, autonomous rod handling, using Teledyne IIS's Bumblebee® X stereo camera. Their solution paired advanced robotic control software with a high-performance stereo vision system.

What Is The Role of Embedded Cameras in Smart Warehouse Automation?

Cameras ensure that warehouse automation systems use visual data to function with consistency. It helps identify, track, and interact in real time. Discover how warehouse automation cameras work, their use cases, and critical imaging features.

The Pressure of Perfect Precision in Robotics Manufacturing

Precision robotics manufacturing is slowly becoming normalized because of its irrefutable positive impact on organizations. However, the journey to create error-free machinery never stops.

RealSense Completes Spinout from Intel, Raises $50 Million to Accelerate AI-Powered Vision for Robotics and Biometrics

The new capital will fuel RealSense's expansion into adjacent and emerging markets and scale its manufacturing, sales and go-to-market (GTM) global presence to meet increased demand for humanoid and autonomous mobile robotics (AMRs).

Battery inspection using machine vision - fast, reliable, and variable

Averna has developed a procedure for automating battery inspection for one of its customers. The fact that potential errors are extremely varied increases the complexity of the inspection process.

How AI, Robotics, and Automation Power Next Generation Pack Assembly

Successful pack assembly systems balance throughput, quality, and safety in real time. Integration matters more than buying the most sophisticated robots; it comes down to seamless software logic, modular failover paths, and smart system design.

Records 1 to 15 of 177

Featured Product

OnLogic Karbon 520 Series of Scalable Rugged Computers

The OnLogic Karbon 520 Series of rugged computers is purpose-built to deliver unwavering performance and reliability in the face of extreme temperatures, vibration, and dynamic power conditions. Powered by the latest Intel® Core™ Ultra processors and validated by MIL-STD-810H testing, the Karbon 520 Series makes it possible to deploy dependable computing for AI at the edge, advanced automation, or critical remote and in-vehicle applications in even the most challenging environments.

Robotics and Automation - Featured Company

Basler

Basler AG is an international leader and experienced expert in computer vision. The company offers a broad coordinated portfolio of vision hardware and software. In addition, it enables customers to solve their vision application issues by developing customer-specific products or solutions. Founded in 1988, the Basler Group employs around 850 people at its headquarters in Ahrensburg, Germany, as well as other sales and development locations throughout Europe, Asia, and North America.

.jpg)

.jpg)

.jpg)