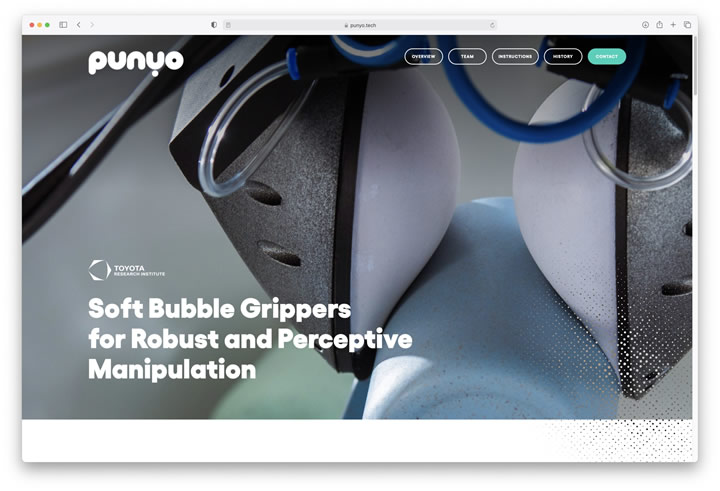

Toyota Research Institute Shares Design to Help Advance the Field of Soft Robotics

The Toyota Research Institute (TRI) is helping to accelerate the field of soft robotics by sharing the design source files and full build instruction for its innovative domestic robot hands.

How Open-Source Robotics Hardware Is Accelerating Research and Innovation

Erico Guizzo for IEEE Spectrum: Weve seen how, over the last several years, open source software-platforms like the Robot Operating System (ROS), Gazebo, and OpenCV, among others-has played a huge role in helping researchers and companies build robots better and faster. Can the same thing happen with robot hardware?

Rethink Robotics Leads in Research and Education with Open Source SDK

Introduces high performance Sawyer robot with software development kit

9 open source robotics projects

Jason Baker for OpenSource: Open source isn't just changing the way we interact with the world, it's changing the way the world interacts back with us. Case in point: open source robotics.

Robots are playing an increasing role in our world, and while we perhaps haven't reached the utopian future with robotic housekeepers imagined for us in the Jetsons, robotics are making advances in fields that fifty years ago would have been completely unimaginable.

While undoubtedly manufacturing has been one of the biggest beneficiaries of the robot renaissance, we are seeing robots enter the mainstream as well. Many of us have robots that clean our floors, clear our gutters, mow our grass, and more.

And now, with the advances of self driving cars, drones, and other transport technologies, the line between what is a robot and what is a vehicle is steadily blurring.

But let's be honest: a lot of us have an interest in robotics simply because it's fun! And the good news is you don't need to be an electrical engineer to enjoy robotics as a hobby. Fortunately, there are a number of open source projects out there that can help even the most novice beginner get started. Full Article:

Records 1 to 4 of 4

Featured Product

Midwest Motion Products is a leading provider of robust and reliable Motion Control Products.

MMP specializes in supplying high-quality Brushed & Brushless DC Motors & Gearmotors for Robotics and Automation Equipment with a wide range of motor windings and gear ratios. With an impressive track record of more than 8,000 released DC Gearmotors designs and over 2,000,000 individual part numbers, we are renowned for our ability to handle large-scale orders. Due to our huge on-hand inventory, we are also well known for lightning-fast delivery of our standard products. We take pride in our dedicated customer service and our team of knowledgeable sales and engineering experts who are ready to assist you with custom design solutions tailored to your specific application. Additionally, we also offer a wide range of complimentary products, such as DC Motor Controls, DC Linear Actuators, AC-DC power Supplies, and DC Servo Amplifiers and others.

Robotics and Automation - Featured Company

Robotmaster

Robotmaster, a Hypertherm Associates brand, is an offline, is an offline robot programming software that helps manufacturers maximize their robot's productivity with easy and efficient robot programming for a variety of applications such as cutting, trimming, milling, welding, spraying, polishing, sanding, grinding, deburring, and more.

Robotmaster uses integrated CAD/CAM functionality to make robotic programming easy and intuitive for everyone, even first-time users.