Autonomous Flying in a Swarm BionicBee - ultralight flying object with precise control

With the BionicBee, the Bionic Learning Network has now for the first time developed a flying object that can fly in large numbers and completely autonomously in a swarm. The BionicBee will present its first flight show at the Hannover Messe 2024.

One person can supervise 'swarm' of 100 unmanned autonomous vehicles, OSU research shows

The findings represent a big step toward efficiently and economically using swarms in a range of roles from wildland firefighting to package delivery to disaster response in urban environments.

H2 Clipper Achieves Major Advanced "Swarm Robotics" Breakthrough For Large Scale Airship Manufacturing

This foundational robotics patent using advanced "swarm robotics" achieves radical reductions of cost and quantum advances in manufacturing techniques for a wide variety of applications-including large scale lighter than air airships.

Molecular Robots Work Cooperatively in Swarms

In a global first, scientists at Hokkaido University have demonstrated that molecular robots are able to accomplish cargo delivery by employing a strategy of swarming, achieving a transport efficiency five times greater than that of single robots.

AGILOX Autonomous Mobile Robots are substantially saving costs by applying Artificial Swarm Intelligence

Swarm Intelligence (SI) and bio-inspired computing have attracted great interest in almost every area of science and engineering, including robotics, over the last two decades.

Hundreds of Tiny Robots Grow Bio-inspired Shapes

Hundreds of small robots can work in a team to create biology-inspired shapes - without an underlying master plan, purely based on local communication and movement.

It Takes a Swarm: These Robots Talk to Each Other, Make Decisions as a Group

As the old saying doesnt exactly go: hundreds of artificial minds are better than one.

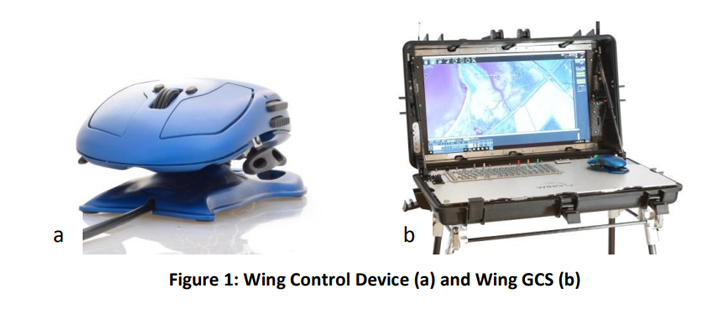

Command and Control of UAV Swarms with the Wing GCS Ground Control Station

While there have been demonstrations of swarms involving up to 1000 UAVs, there are few examples of use in practical scenarios. One reason for this is the difficulty of effectively organising and controlling the swarm using a standard transmitter and laptop computer.

OSU researcher part of DARPA grant for autonomous drone swarms

An Oregon State University computer science professor is part of a team that will receive up to $7.1 million to develop a drone swarm infrastructure to help the U.S. military in urban combat.

Swarm of Underwater Robots Mimics Ocean Life

UCSD: Underwater robots developed by researchers at Scripps Institution of Oceanography at the University of California San Diego offer scientists an extraordinary new tool to study ocean currents and the tiny creatures they transport. Swarms of these underwater robots helped answer some basic questions about the most abundant life forms in the ocean—plankton.

Scripps research oceanographer Jules Jaffe designed and built the miniature autonomous underwater explorers, or M-AUEs, to study small-scale environmental processes taking place in the ocean. The ocean-probing instruments are equipped with temperature and other sensors to measure the surrounding ocean conditions while the robots “swim” up and down to maintain a constant depth by adjusting their buoyancy. The M-AUEs could potentially be deployed in swarms of hundreds to thousands to capture a three-dimensional view of the interactions between ocean currents and marine life. Cont'd...

3 Micro Drones & Robot Swarms Initiatives Backed by the US Military

DARPAs FLA program aims to create unmanned nano robot like insects & birds that can go into buildings & perform key activities that will not be possible by Humans.

Records 1 to 11 of 11

Featured Product

Robotmaster 2024

Program multi-robot cells and automatically solve robotic errors with ease. Hypertherm Associates announces a new version to its robotic programming software. Robotmaster 2024 addresses key market trends including the support for programming multiple robots in a single work cell and the demand for automatic trajectory optimization and robotic error correction.

Robotics and Automation - Featured Company

ResinDek / Cornerstone Specialty Wood Products

As the manufacturer of ResinDek® panels, we have been at the forefront of testing and innovating flooring panels for the Material Handling Industry since 1994. In 2007, we began providing ResinDek panels for automated warehouse distribution robots. Much of our initial research and development occurred with Automated Guided Vehicles. In the last decade, we have provided a variety of ResinDek engineered flooring products to numerous Automated Guided Vehicles (AGV) and Autonomous Mobile Robot (AMR) manufacturers for their testing labs. As a result, millions of square feet of ResinDek panels are in service worldwide with robotic traffic in distribution centers, warehouses, microfulfillment centers, and retail environments.