Robotics and Automation - Articles, Stories & Interviews

Why Robots Are About to Change Everything AND WHY NOW

The convergence of AI breakthroughs and robotics is creating a moment for which the field has been waiting decades.

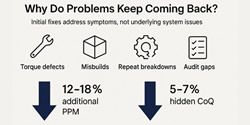

KPI Growth has an enemy called “Recurrence” - Fight it with Standard Work to Sustain the Growth.

Continuous Improvement is often misunderstood as an engine for solving more problems. In reality, the defining capability of a mature operation is ensuring the same problems never return.

Fully Autonomous Deliveries inside Multi-floor Buildings without Elevator APIs

Once a robot can move between floors without any changes to existing building infrastructure, operators get immediate ROI by freeing staff from repetitive delivery work while improving speed and convenience for residents and guests.

Stefa Mini Solutions for Next-Generation Robotic Applications

The Stefa Mini, Cassette and Nano Seals all have smaller cross sections than comparable seals in the market today. This matters because a smaller seal allows for smaller glands (the area the seal slips into on the equipment) and smaller glands mean overall smaller equipment.

Facility Maintenance: Lavo Bot AI and NVIDIA Bring Autonomy to Exterior Surface Cleaning

Equipped with advanced mapping, multi-sensor vision and zone-based safety, the system navigates real-job sites with confidence—handling up to 6,000 sq ft/hour and supporting pressure-wash rigs up to 12 GPM and 4,500 PSI.

The ifm Obstacle Detection System (ODS)

The ifm Obstacle Detection System (ODS) optimizes the robot's overall performance by treating obstacle detection as a holistic system rather than just a camera. It provides reliable obstacle detection to protect people, equipment, and mobile robots.

Physical AI and Autonomy in the Construction Industry

Bedrock is taking advantage of the dramatic accessibility of GPUs and frameworks for scaled data access and training, combining it with our unique understanding of how to build and create autonomy solutions quickly and efficiently.

Robotics and Automation - Featured Stories

Aerospace's Automation Breakthrough: How Robotics and AI Orchestration Are Rewriting the Supply Chain

For aerospace, the next leap will come from integrating physical automation with AI systems capable of coordinating the flow of information across complex, multi-vendor, secure environments that protect confidential information all while transforming efficiency..

How to Build a Digital Foundation for Your Robotics and Automation Strategy

A strong digital foundation brings everything together, allowing automation initiatives to scale, adapt and perform as intended. Without it, automation efforts often stall before they reach their full potential.

Powering Robotics: How Networks Enable the Era of "Physical LLMs"

Physical AI describes intelligent systems that can sense, interpret, and act in real environments. Think of self-driving cars navigating busy streets, robotic arms assembling machinery with precision, or smart grids adapting in real time to energy demands.

Robotics and Automation - News Headlines

LUCID Launches Helios2 Wide Chroma, a Factory-Calibrated IP67 RGB-D Camera

The Helios2 Wide Chroma combines LUCID's Helios2 Wide Time-of-Flight (ToF) 3D camera with a 12.2 MP Triton® RGB camera into a rugged, space-saving unit. Featuring a wide

108° × 78° field of view, the camera captures large scenes at close range, making it ideal for applications requiring broad spatial coverage without mechanical repositioning.

FORT Robotics Launches Wireless E-Stop Pro: Real-Time Wireless Safety for Complex Industrial Environments

Designed to unlock robotic productivity in warehousing, manufacturing, and construction, the new Pro model provides the fail-safe control necessary for large-scale autonomous operations

Pickit 3D launches major release of its 3D robot vision solution

Simpler, more powerful and more resilient

AGIBOT Tops IDC Robot Ranking in Five Major Application Scenarios

New IDC report highlights AGIBOT's global leadership in multi-scenario deployment, from industrial manufacturing to interactive commercial services

New Data Reveals Why Manufacturers Can't Compete for Robotics Talent: A 2x Salary Gap

"The data reveals that manufacturing's hiring challenge isn't about finding qualified engineers. It's about competing with industries paying twice as much," said James Dam, founder of CareersInRobotics.com. The disparity is industry-wide, affecting every sector of the robotics market.

Robotics and Automation - Featured Product

ResinDek TRIGARD ESD ULTRA FOR HIGH-TRAFFIC ROBOTIC APPLICATIONS

To maximize the productivity of an autonomous mobile robot (AMR) or automatic guided vehicle (AGV) deployment, it's critical to create the optimal environment that allows the vehicles to perform at their peak. For that reason, Cornerstone Specialty Wood Products, LLC (www.resindek.com) created the TriGard ESD Ultra finish for its ResinDek engineered flooring panels. The TriGard ESD Ultra finish is ideal for high-traffic robotic applications characterized by highly repetitive movement patterns and defined travel paths.

Robotics and Automation - Featured Company

Electrocraft Inc.

ElectroCraft, Inc. is a global provider of dependable, application-engineered fractional-horsepower motor and motion products. Our products are found in thousands of different applications within industrial, commercial, and consumer product markets. While ElectroCraft provides a wide array of standard products with many configurable options, we have built our brand on custom OEM solutions that meet the precise performance, cost and quality our customers require.

.jpg)