Hybrid AMRs are a Game-Changer

They can operate seamlessly in unstructured environments and adapt to changing floor conditions. At particular points where highest precision is required, we revert to a QR code location.

Automation's Future in Sustainable Transportation

From an operational standpoint, the role of robotics and automation in battery swapping is pivotal. Automated guided mechanisms handle each module, reducing labor costs and minimizing human error.

Addressing Challenges in Software Solutions for Robots and Physical AI

We leveraged our long heritage and leadership in robotics to create an AI software product that helps our customers overcome the challenges of traditional automation, accelerate set-up and deployment, and achieve greater ROI from their existing automation systems.

Automate 2025 Q&A with DESTACO

There's nothing like seeing our products in action. We will have live demonstrations, giving attendees the chance to see the performance and capabilities of our solutions up close and personal.

Automate 2025 Q&A with IDS Imaging

We will be exhibiting our latest and upcoming camera technologies including our newest Event based camera, an upcoming time of flight camera and our new streaming camera family.

Automate 2025 Q&A with igus

We will show how our components can help bring automation machinery to the next level by using our components but also how our robotics department can solve your problems for you with our robotics platform called RBTX.com.

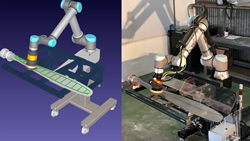

AI-Driven Grasp Depth Estimation

The core innovation of our new patent lies in its self-supervised approach to depth estimation. What that means is, the AI learns to judge the depth of an item it needs to pick up by using its own sensor data and the feedback it gets from its actions.

Real-Time, High-Resolution Stereo Vision for Industrial Robotics

Software alone isn't always enough to tackle the demands of real-time stereo vision. That's where smart hardware solutions come into play. Think of it as having a specialist to take care of the heavy lifting so you can focus on the big picture.

ProMat Q&A with Agilox

For the first time ever, AGILOX will showcase four different AMR models operating simultaneously in a live tradeshow environment. Attendees will experience real-world automation in action just like in an actual manufacturing facility.

ProMat Q&A with Swisslog Americas

Visitors to the booth can learn how the company's entire portfolio of best-in-class robotics and software solutions can help achieve new levels of efficiency in a variety of applications, including food and beverage, general merchandise, apparel and omnichannel warehousing.

ProMat Q&A with Piab

Piab's exhibit at ProMat 2025 will highlight its dedication to advancing logistics and warehousing operations through cutting-edge vacuum technology.

ProMat Q&A with ForwardX Robotics

Visitors can engage with our top specialists, explore behind-the-scenes automation logic, and discover how our solutions drive operational excellence. Don't miss the chance to see innovation firsthand and learn how we can optimize your workflow!

Celebrating10 years of Innovation in Robotics

Celebrating its 10th anniversary, global robot programming software company RoboDK reflects on a decade improving robot deployment. In this Q&A CEO Albert Nubiola looks ahead to continue their mission of making robotics accessible to all.

ANYbotics ANYmal robot is addressing key challenges in Industrial Robotics

The ANYmal robot addresses key challenges in industrial operations by offering autonomous, highly mobile inspection capabilities in complex and hazardous environments. Its four-legged design enables navigation through uneven terrains, stairs, and confined spaces.

Micropsi Industries' moves HQ from Berlin to the U.S.

The United States is the second largest manufacturing center in the world (after China). With the growing trend of reshoring manufacturing operations, companies are increasingly looking for automation solutions.

Records 1 to 15 of 168

Featured Product

Model TR1 Tru-Trac

The Model TR1 Tru-Trac® linear measurement solution is a versatile option for tracking velocity, position, or distance over a wide variety of surfaces. An integrated encoder, measuring wheel, and spring-loaded torsion arm in one, compact unit, the Model TR1 is easy to install. The spring-loaded torsion arm offers adjustable torsion load, allowing the Model TR1 to be mounted in almost any orientation - even upside-down. The threaded shaft on the pivot axis is field reversible, providing mounting access from either side. With operating speeds up to 3000 feet per minute, a wide variety of configuration options - including multiple wheel material options - and a housing made from a durable, conductive composite material that minimizes static buildup, the Model TR1 Tru-Trac® is the ideal solution for countless applications.