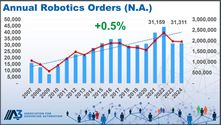

A3 Reports North American Robotics Market Holds Steady in 2024 Amid Sectoral Variability

RobotsTrader.com Launches as Premier Marketplace for Buying and Selling Used Robots

The most sensitive and durable robot hand yet created

Top 5 trends for the AIoT industry in 2025

MassRobotics Opens Applications for Third Annual Form and Function Robotics Challenge

How Robot Sensors Are Powering a USD 5 Billion Revolution by 2032

IEEE Reveals Predictions for Top Technology Trends of 2025

Dürr equips first BYD plant in Europe with sustainable painting technology

OSARO CEO Derik Pridmore's 2025 Robotics Predictions: AI-Powered Solutions and Practical Automation Take Center Stage

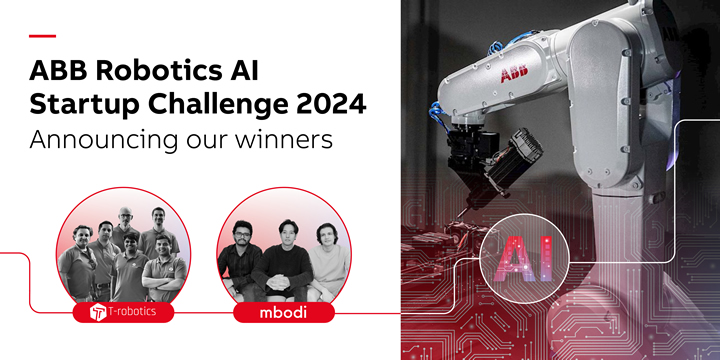

ABB Robotics names T-Robotics and Mbodi as AI Startup Challenge Winners

Beyond the Beaker: Robots and AI Take Center Stage in Modern Chemistry

The Battle of Price and Progress: Making AI Affordable for the Smaller Businesses

Can cobots attract more young talent to welding?

Can Predictive AI Lead Robotics Education to Its Next Evolution?

New TI MCUs enable edge AI and industry-leading real-time control to advance system efficiency, safety and sustainability

Records 16 to 30 of 920

First | Previous | Next | Last

Industrial Robotics - Featured Product

.jpg)

.jpg)