'Eyes, hands, brains and mobility' will define robotics beyond 2025

Building on 50 years of robotics leadership, 2025 marks the beginning of a new era of AI application in industrial robotics. Launch of new ABB Robotics brand film unveils new levels of versatilty for robots to do more tasks, in more places.

OSARO CEO Derik Pridmore's 2025 Robotics Predictions: AI-Powered Solutions and Practical Automation Take Center Stage

As we enter 2025, the robotics landscape is evolving rapidly. Derik Pridmore, co-founder and CEO of OSARO, a leading provider of AI-powered robotics solutions for industrial automation, shares his expert predictions for the year ahead.

Top Viewed Articles of 2024

RoboticsTomorrow readers sought out Use Cases and Expert Insights to help guide them through the rapid changes happening throughout the industry. Here are the Top 4 Viewed articles from 2024.

The next wave of humanoid robotics: how emerging tech is reshaping the future of automation

As the founder of Humanoid and someone who's been in the tech startup space for over a decade, I've seen firsthand how advanced technologies can transform industries as well as how quickly this transformation can take place.

Zebra Study: Only 16% of Manufacturers Have Real-Time Visibility into Manufacturing Production

While digital transformation is a priority for manufacturers, achieving it is fraught with obstacles, including the cost and availability of labor, scaling technology solutions, and the convergence of information technology and operational technology (IT/OT).

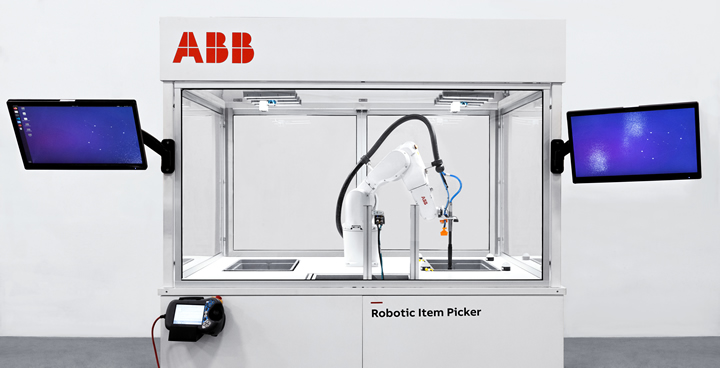

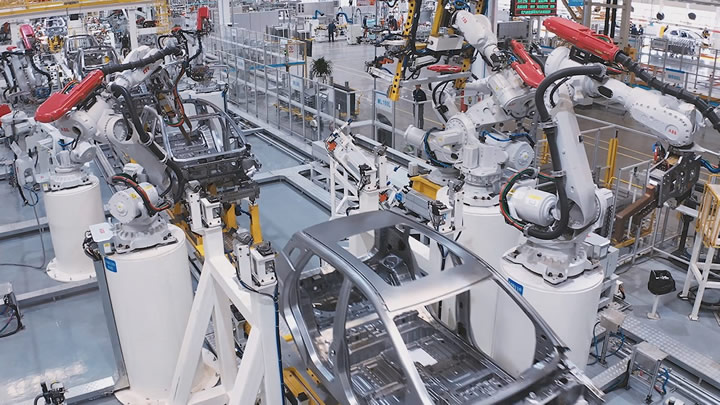

ABB identifies new frontiers for robotics and AI in 2024

Marc Segura, President ABB Robotics Division, identifies three drivers for robotics-driven AI solutions in 2024, as ABB continues expansion into new segments not previously served by robotic automation.

Top 5 Robot Trends 2024 - International Federation of Robotics reports

The stock of operational robots around the globe hit a new record of about 3.9 million units. This demand is driven by a number of exciting technological innovations. The International Federation of Robotics reports about the top 5 automation trends in 2024:

Trends in Industrial Robotics to Watch in 2024

This article aims to dissect the trends within the four major categories of industrial robotics: SCARA robots, collaborative robots (cobots), gantry robots, and articulated robots.

Four predictions for 2024: AI set to supercharge robotic automation

We've reached that point in the year when it's time to reflect upon the trends from the past 12 months, while looking ahead at what 2024 has in store for the world of robotics and automation.

What's in store for 2024: Top 5 industry trends

The manufacturing industry is undergoing significant changes due to the swift advancement of technology and evolving global dynamics.

Renaissance of Robotics: The Top 10 Marvels in the Post-COVID Age

Brace yourself as we dive into the top 10 incredible advancements that arose after 2020 and are radically changing the way we live, work and play.

ABB predicts top US robotics trends

Labor shortages present new opportunities for robotic automation. AI and connected digital networks will make robots easier to use, enabling them to take on more tasks in new industries.

5 Robotics Trends in 2022

2021 was a transformative year in development, adoption, funding, and M&A activity in the robotics industry. 2022 is off to a robust start and all signs point to rapid robotics growth over the next decade. Below are five key robotics trends to watch in 2022.

ABB predicts key trends that will change robotic automation in 2022

Post-pandemic acceleration continues for robots in new sectors like logistics and retail, and speeds up for EV production. Adoption of robots driving demand for new skills that require education and training.

Digital Transformation and Industrial Robots Outlook

Whilst initially a temporary measure to resolve manpower shortages and high employee costs, many companies are now investing in smart robotics as a permanent and long-term measure in a post-pandemic world.

Records 1 to 15 of 103

Featured Product

New incremental encoder IERF3 L from FAULHABER

FAULHABER is expanding its product range with the ultra-precise incremental encoder IERF3 L. Thanks to the optical measuring principle and state-of-the-art chip technology, the device offers the highest resolution, excellent repeatability, and outstanding signal quality. In typical applications, the positioning accuracy is 0.1° and the repeatability 0.007°. This makes the encoder the perfect solution for high-precision positioning applications in confined spaces.

Robotics and Automation - Featured Company

PNY

PNY Professional Solutions provides customers with powerful tools to manage heavy workloads. PNY offers NVIDIA Professional, Consumer GeForce RTX, and Data Center GPU Solutions, along with PNY Memory upgrades and Solid-State Drives. All PNY products are designed and built with system integrators in mind to provide advanced application performance, top productivity, and greater power efficiency.

.jpg)

.jpg)

.jpg)