Advancing Machine Design with the Power of Collaboration and AI

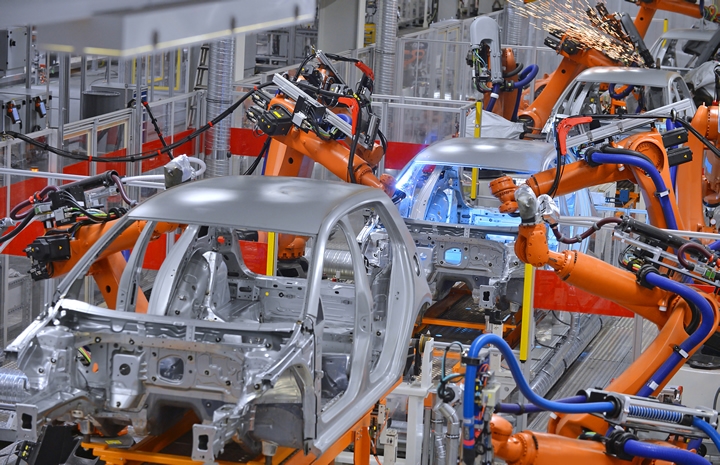

Beyond Protection: How Advanced Sealing Solutions Are Enhancing Robotic Performance

Stretch Helps Gap Inc. Deliver for Its Customers

Barriers to investing in CNC automation in 2025

A3 Releases Vision for a U.S. National Robotics Strategy

The Reshoring Revolution: Navigating New Policies For A Manufacturing Renaissance

NGen, Humber Polytechnic, and Festo Didactic Showcase Canadian Skills at Hannover Messe 2025

ProMat Q&A with Agilox

Automation and Humans: Will We Be Replaced?

Low-Cost Robotics Elevate Industrial Inspection Processes

ProMat Q&A with Swisslog Americas

RightHand Robotics Announces Strategic Investment from Rockwell Automation

Robotic Software Market is Poised to Surpass USD 150 Billion by 2034

'Eyes, hands, brains and mobility' will define robotics beyond 2025

ProMat Q&A with Piab

Records 31 to 45 of 1238

First | Previous | Next | Last

Factory Automation - Featured Product

.jpg)