Filics secures €13.5M in financing to expand and roll out its robotics platform

The "Filics Unit" is the first product and consists of two omnidirectional robots that have been specially developed for handling Euro pallets. The system moves autonomously through the warehouse, traveling under pallets and transporting them.

The Human + Robot Workforce: How Collaborative Robotics Are Solving the Labor Crisis

Collaborative robotics like person-to-goods or "pick assist" AMRs are intelligently designed to work with people, not replace them. Adoption of AMRs for automated order fulfillment is turning this challenge into a competitive advantage.

How to Choose the Right NDT Methods for Robotics Manufacturing

With so many NDT options available, the best one depends on the specific materials and functions in question. As a result, it is often most helpful to vary methods between components.

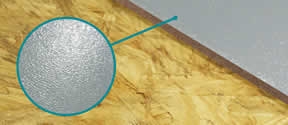

Upgrade Your Mezzanine Flooring While Avoiding Timely and Costly Replacement

Mezzanine floors are important in many facilities. They provide extra space for storage or work without taking up more ground space. However, they often face heavy use from equipment and people. Over time, this can cause the floor to wear down.

ABB introduces most compact, AI-powered AMR for payloads up to 1500 kg

AI-driven Visual SLAM and integrated load sensing enable stable and autonomous navigation, including in challenging conditions. AMR Studio 4.0 version simplifies deployment with no-code programming and real-time fleet management

Hybrid AMRs are a Game-Changer

They can operate seamlessly in unstructured environments and adapt to changing floor conditions. At particular points where highest precision is required, we revert to a QR code location.

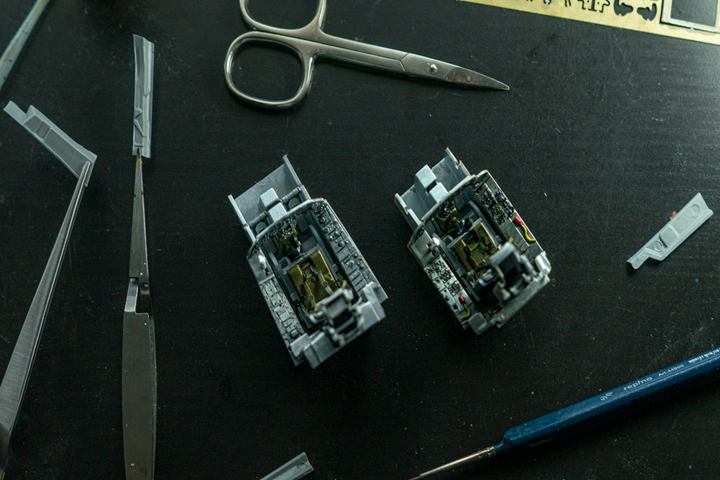

DESTACO Unveils the eRDH Series Electric Parallel Gripper: The Future of Automated Handling

This latest addition to the DESTACO Robohand product line represents a significant leap forward in gripping technology, offering unparalleled precision, flexibility, and ease of use.

How Autonomous AI Tackles Quality Control Costs

Quality is often viewed as a direct driver of customer satisfaction and operational efficiency in manufacturing. Yet some organizations fail to recognize the hidden costs of quality issues, significantly impacting the bottom line.

Battery inspection using machine vision - fast, reliable, and variable

Averna has developed a procedure for automating battery inspection for one of its customers. The fact that potential errors are extremely varied increases the complexity of the inspection process.

How to Achieve the Full Benefits of a Warehouse Digital Twin

A warehouse digital twin needs more than a highly capable WMS, it also needs a reliable technology to capture all the necessary inventory data, and this is where computer vision plays a pivotal role.

Physical AI: Embracing AI's Moment in Robotics

Manufacturers currently use automation to streamline workflows, enhance efficiency, cut costs, and meet growing consumer demands. Yet they face a myriad of disruptions such as labor shortages, limitations of current technologies, and costly downtimes on production lines.

How AI, Robotics, and Automation Power Next Generation Pack Assembly

Successful pack assembly systems balance throughput, quality, and safety in real time. Integration matters more than buying the most sophisticated robots; it comes down to seamless software logic, modular failover paths, and smart system design.

Legal Considerations for Robots-as-a-Service (RaaS) in Warehousing

Understanding the nuances of RaaS agreements is key to maximizing its benefits. From implementation fees to site licensing and maintenance responsibilities, a well-structured contract ensures that both vendors and operators are aligned on expectations and obligations.

What Is the Difference between Wi-Fi and Industrial Wireless Networks?

Traditional wireless technologies like Wi-Fi, while great in consumer environments, often fall short of meeting the stringent requirements of industrial settings and specific factory automation applications and machine deployments.

How Is Modular Robot Design Reshaping Factory Automation?

How industrial robots work constantly adapts to increased demand and novel technologies, but it enhances automation potential the most. What is shifting and how can production engineers and electronics experts in these sectors fully leverage the benefits?

Records 1 to 15 of 1240

Factory Automation - Featured Product

Next-Level Vision with HALCON 25.05

HALCON 25.05 sets new standards for machine vision, introducing Deep 3D Matching for robust bin picking, enhanced OCR accuracy, improved QR code reading on curved surfaces, and smarter camera integration. Meet MVTec at Automate Detroit and experience how the latest deep learning technologies and development tools empower you to create faster, more reliable, and flexible industrial solutions.

.jpg)