The future of manufacturing: How cobots can combine with robot offline programming and 3D simulation

How Small Manufacturers are Building a Business Case for Robotics

Why Letting the Machines Do the Tending Will Open the Door to the Next Industrial Revolution

Utilizing Cobots to Manage Labor Shortages

Maximizing the Value of Collaborative Robots

World's most remote robot automates Amazon reforestation project

Welcome to the Age of the Cobot

Machine Shop Robots Get Real

FORVIA

Universal Robots Predicts 2023 Automation Trends Helping Manufacturers Meet New-Year Goals

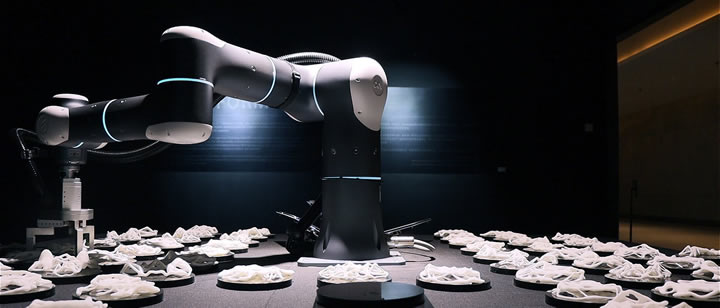

Flexiv's Rizon Robot Used in Avant-Garde Art Installation

6-axis robots for injection molding open possibilities for manufacturers

Universal Robots' New UR20 Collaborative Robot Makes U.S. Debut at IMTS 2022, Expanding Cobot Automation in Machining Industry

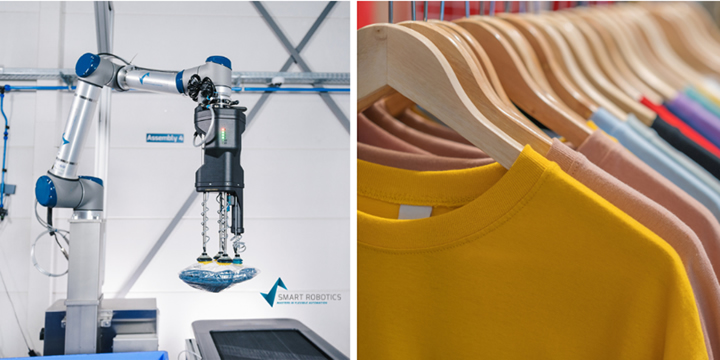

Smart Robotics announces the launch of their latest design in Warehouse Automation - the Smart Fashion Picker

Automating Labor Dependent Tasks in High Mix/Low Volume Production

Records 16 to 30 of 100

First | Previous | Next | Last

Featured Product

Harmonic Drive - Coming Soon! Integrated Actuators with EtherCAT

Robotics and Automation - Featured Company

.jpg)

.jpg)

.jpg)