Automate 2025 Q&A with DESTACO

There's nothing like seeing our products in action. We will have live demonstrations, giving attendees the chance to see the performance and capabilities of our solutions up close and personal.

Automate 2025 Q&A with Zimmer Group

We have evolved from a manufacturer of single components to becoming a full-range provider of complex system solutions in the field of robotics. Our portfolio covers the entire automation spectrum - from high-functioning grippers to robot accessories.

Maximum process reliability for the protein source of the future

For more than 30 years, the SCHUNK PGN-plus-P gripper has been the most versatile gripper on the market, and is constantly finding new applications. A current and unusual application example is the use in the automated production of animal feed from insect larvae in Austria.

Longer tool service life, lower energy consumption

It has become essential for production companies to manufacture in a climate-friendly and economical way. With process-integrated measures, pollutant emissions and the use of resources must be kept as low as possible, while protecting and relieving the burden on employees.

DESTACO Smart Electric Product Line of Clamps and Guides

The new smart electric product line represents a substantial leap forward in the automation and industrial clamping landscape, offering enhanced precision, energy savings, and seamless integration for modern manufacturing processes.

Productivity Inc. Wants Your Robot to Do More

Using ATI's QC-11 Tool Changer and RCT-151 Radially-Compliant Deburring Tool along with a Renishaw probe, they produced a demonstration highlighting their expertise in aiding potential customers to maximize productivity of the robots already installed in their facilities

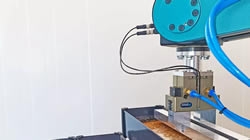

Ideal Spindles for High-Speed Robotic Milling of Plastics and Composites

One application for which robot arms are well suited is using a kind of deburring tool as a cutting instrument when working with relatively soft materials like plastics and composites.

Talking AUTOMATE 2023 with Stäubli

When you visit us at booth 2632, you will be able to experience a live demo of our robotic tool changer system, as well as our new end-of-arm-tooling solutions for material handling in automated manufacturing processes including gripping, suction, and cutting.

Intelligent Box Opening Device (IBOD)

You have lots of cartons coming into a typical warehouse, let's say 600 boxes per hour, and razor blades are used to cut these boxes while keeping up with intake speeds. This invites risks and employees still get injured, despite safety precautions.

End-of-Arm-Tooling powered by Stäubli Fluid Connectors

Stäubli Fluid Connectors presents a new End-of-Arm-Tooling range: The mechatronics specialist offers a broad technology portfolio from a single source coupled with advice for individual solutions in robotic material handling.

4 Critical Considerations When Selecting a Robotic End-Effector System

Finding and implementing the perfect end-effector system is reliant on the user giving due consideration to four critical areas. Only when complete understanding of the needs in these four realms is acquired can an educated end-effector choice be made.

HP Multi Jet Fusion 3D Printing Technology for End of Arm Tooling

When HP set out to develop this technology, the aim was to push beyond prototyping and enable repeatable, higher volume additive manufacturing. We can do this by combining a powder bed fusion approach with HP's Thermal Inkjet (TIJ) technology.

ArtiMinds and ATI Accelerate Technology Implementation with Greene Tweed

Choosing the right automation partners led Greene Tweed to quickly develop, integrate and install a more flexible automated material removal cell.

Metal 3DPrinting over CNC for custom EOAT

This small component was stopping them from realizing the full potential of their manufacturing process as they could only run the system when there was someone there to restart the system if a stoppage occurred due to slippage.

How Robotics is Transforming Manufacturing

When you sell a robot, the amount of additional required pneumatic components, sensing products, vision inspection systems and machine safety products can cost as much or more than the robot itself. Every robot sold has an exponential economic ripple effect.

Records 1 to 15 of 26

Featured Product

Midwest Motion Products is a leading provider of robust and reliable Motion Control Products.

MMP specializes in supplying high-quality Brushed & Brushless DC Motors & Gearmotors for Robotics and Automation Equipment with a wide range of motor windings and gear ratios. With an impressive track record of more than 8,000 released DC Gearmotors designs and over 2,000,000 individual part numbers, we are renowned for our ability to handle large-scale orders. Due to our huge on-hand inventory, we are also well known for lightning-fast delivery of our standard products. We take pride in our dedicated customer service and our team of knowledgeable sales and engineering experts who are ready to assist you with custom design solutions tailored to your specific application. Additionally, we also offer a wide range of complimentary products, such as DC Motor Controls, DC Linear Actuators, AC-DC power Supplies, and DC Servo Amplifiers and others.

Robotics and Automation - Featured Company

IDS Imaging Development Systems Inc.

World-class image processing and industrial cameras "Made in Germany". Machine vision systems from IDS are powerful and easy to use. IDS is a leading provider of area scan cameras with USB and GigE interfaces, 3D industrial cameras and industrial cameras with artificial intelligence. Industrial monitoring cameras with streaming and event recording complete the portfolio. One of IDS's key strengths is customized solutions. An experienced project team of hardware and software developers makes almost anything technically possible to meet individual specifications - from custom design and PCB electronics to specific connector configurations. Whether in an industrial or non-industrial setting: IDS cameras and sensors assist companies worldwide in optimizing processes, ensuring quality, driving research, conserving raw materials, and serving people. They provide reliability, efficiency and flexibility for your application.