Kassow Robots' Edge Edition 7-axis Collaborative Robot Arm

The SPT-1500UL from SEER Robotics

The Emergence of Mechatronic Subsystems and Their Importance in Product Deployment

Key Considerations for Maximizing Manufacturing Efficiency

Talking PACK EXPO Las Vegas with CMES Robotics

Talking PACK EXPO Las Vegas with igus

Adaptive Robots

Wearable Robotics and Exoskeleton Technology

Hybrid AMRs are a Game-Changer

Automation's Future in Sustainable Transportation

Addressing Challenges in Software Solutions for Robots and Physical AI

Automate 2025 Q&A with DESTACO

Automate 2025 Q&A with IDS Imaging

Automate 2025 Q&A with igus

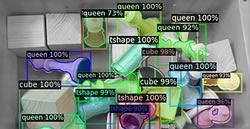

AI-Driven Grasp Depth Estimation

Records 16 to 30 of 190

First | Previous | Next | Last

Featured Product

MVTec MERLIC 5.8

Robotics and Automation - Featured Company