Multi-axis motion control drives pipe-based robots

Surveying and maintaining underground pipes can be complex and resource intensive. To streamline the process, construction and facility management teams are increasingly turning to robots that can provide inspection as well as repair.

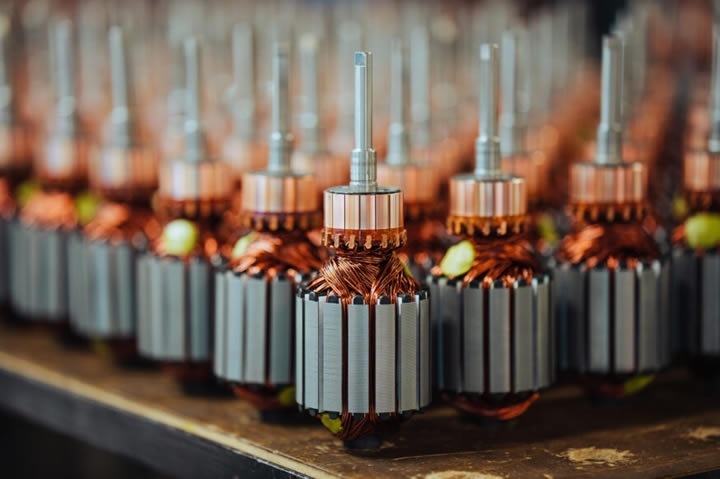

Understanding Torque and Speed in Electric Motors

The higher the torque, the greater the ability to rotate heavy objects, overcome tough resistance or to transport objects vertically. Applications which rely on high torque can include hoists and cranes, as well as industrial mixing machines.

Walking naturally with artificial foot

The gait becomes more harmonious, more stable and less tiring. An intelligent controller finds the correct gait rhythm and a brushless motor from FAULHABER provides the necessary propulsion.

Testing drive systems virtually - Simulink library for development and digital twin.

How will the drive actually behave in the real-life application? For brushless DC-motors from FAULHABER, this question can be answered without any hardware whatsoever.

Robots speeding up material handling

With omnidirectional movement and smart docking with virtually any warehouse cart in under 20 seconds, these new robots are making material handling faster and safer.

At least 60 million strokes

A "compact automation" is a mechatronic system that performs a whole series of consecutive production steps autonomously. "Compact" refers to the small dimensions, in the millimeter and centimeter range, of the products to be processed.

The rise of modular robots and the importance of drive train design

As part of an in-house robot build, optimizing the drive train that powers and controls each joint is vital to the robot's performance. The most effective way of achieving this is by developing the drive train as a complete module.

The most compact Motion Control System on the market

FAULHABER is introducing a new Motion Control System. More precisely: The world's smallest Integrated Motion Controller.

Optimizing Material Handling Processes for Increased Efficiency

Over the past few years, all aspects of the warehousing sector have been automated and this naturally includes the materials handling processes. This automation has increased efficiency across the board as well as improving employee safety and productivity.

DC microdrives bring dynamics into handling

Miniature drives and microdrives can be found in virtually all areas of automation technology and have a correspondingly wide variety of applications. These range from medical technology and laboratory automation.

Autonomous towing robots speeding up material handling

With omnidirectional movement and smart docking with virtually any warehouse cart in under 20 seconds, these new robots are making material handling faster and safer.

Motors and Motion Control Technologies in Orthopedic Surgical Robotics

Motors found inside orthopedic tools normally serve as the primary power source for driving devices like bone saws, drills or shavers. In these variable speed applications, motors need to be exceptionally small in diameter, lightweight & capable of running at high speed.

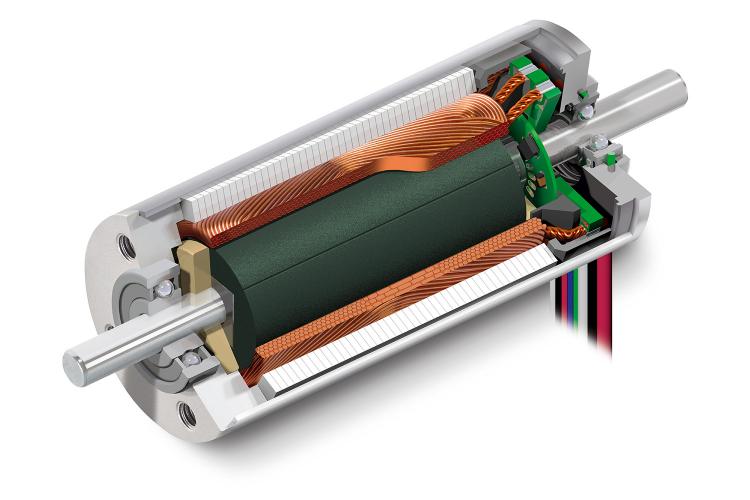

When to Choose a 4pole DC Motor

A 4pole design is stronger than a 2pole equivalent but can also fit within the same space and weight envelope. Greg Dutfield of maxon UK explains.

Can robots care? - Coreless motors driving patient care robots

FAULHABER's SR motor series is ideal for healthcare robot applications. Supplied by EMS in the UK and Ireland, the motors are designed for optimum power and performance while minimising weight and size.

How to Select the Right Motor for Your Robot

As both an industry and an entire class of technology, robotics changes and advances rapidly. Whether as a hobbyist or seasoned robotics engineer, you need to know each component inside and out. You should also know how to choose between several different variations.

Records 1 to 15 of 35

Featured Product

Oriental Motor USA - Ideal for AGV/AMR Applications

The BLV Series R Type brushless DC motor (BLDC motor) speed control system offers the design of motor and driver significantly reduced in size and weight, yet high-power, and contributes to the battery driven automation. The BLV Series R Type is compatible with the two interfaces of Modbus (RTU) and CANopen communication.

Robotics and Automation - Featured Company

Oriental Motor Corp. USA

Since our founding in Japan in 1885, Oriental Motor globally has been providing the optimal motion systems as part of our total service, to meet the widest market demands. We manufacture and sell AC Motors, Stepper and Servo Motors, Linear and Rotary actuators, Network Solutions, Accessories and Thermal Management solutions. Oriental Motor's sales and service network is international, with offices throughout North America, Europe and Asia.