See what this squishy octopus-inspired robot can do

The latest revolutionary robot isn’t the metallic, costly machine you’d expect: It’s squishy like Silly Putty, wireless, battery-less and made for pennies by a 3D printer.

Meet Octobot. It looks like a tiny octopus and is designed to mimic that slithery creature to get through cracks and tight places, making it ideal as a rescue robot.

A team at Harvard University has created a robot - actually about 300 of them, since they are so cheap to make - that is opposite of the common view of a robot. Soft, not hard. Flexibl,e not rigid. It’s not mechanical, nor electrical. It’s powered by fluids. The discovery is described, photographed and shown on video in the scientific journal Nature. Cont'd...

Robot Octopus Points the Way to Soft Robotics With Eight Wiggly Arms

Cecilia Laschi for IEEE Spectrum: The sun was sparkling on the Mediterranean Sea on the afternoon when a graduate student from my lab tossed our prize robot into the water for the first time. I watched nervously as our electronic creation sank beneath the waves. But the bot didn’t falter: When we gave it the command to swim, it filled its expandable mantle with water, then jetted out the fluid to shoot forward. When we ordered it to crawl, it stiffened its eight floppy arms in sequence to push itself along the sandy bottom and over scattered rocks. And when we instructed it to explore a tight space beneath the dock, the robot inserted its soft body into the narrow gap without difficulty.

As a professor at the BioRobotics Institute at the Scuola Superiore Sant’Anna, in Pisa, Italy, I lead a team investigating soft robotics. This relatively new field of research has the potential to upend our ideas about what robots are capable of and where they can be useful. I chose to build robots that mimic the form of the octopus for two reasons. First, because they’re well suited to demonstrate the many advantages that come when a machine can flex and squish as needed. Also, it’s an excellent engineering challenge: An octopus with eight wiggly arms, which must work together in the face of complex hydrodynamic forces, is very difficult to design and control. Cont'd...

Artificial muscle for soft robotics: Low voltage, high hopes

Phys.org: Soft robots do a lot of things well but they're not exactly known for their speed. The artificial muscles that move soft robots, called actuators, tend to rely on hydraulics or pneumatics, which are slow to respond and difficult to store.

Dielectric elastomers, soft materials that have good insulating properties, could offer an alternative to pneumatic actuators but they currently require complex and inefficient circuitry to deliver high voltage as well as rigid components to maintain their form—both of which defeat the purpose of a soft robot.

Now, researchers at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) have developed a dielectric elastomer with a broad range of motion that requires relatively low voltage and no rigid components. They published their work recently in Advanced Materials. Cont'd...

'Squishy' Motors and Wheels Give Soft Robots a New Ride

Rutgers engineers, in a breakthrough, create a soft motor that could power versatile soft robots

New Muscle-Inspired Actuators Hold Potential to Build Safer, Soft-Bodied Robots

Robots should be safer and softer in order to make them more cooperative and execute tasks in close contact with humans. George Whitesides, Ph.D., a Core Faculty member at Harvard’s Wyss Institute for Biologically Inspired Engineering and the Woodford L. and Ann A. Flowers University Professor of Chemistry and Chemical Biology in Harvard University’s Faculty of Arts and Sciences (FAS), along with his team, has created a new actuator that moves like human skeletal muscles by using vacuum power for automating soft, rubber beams.

These actuators are soft and shock absorbing similar to real muscles, and do not pose any danger to their surroundings or the human beings working along with them or the future robots containing them. This study was published in the June 1 issue of the Advanced Materials Technologies journal. Cont'd...

Tether free actuator hailed as soft robotics breakthrough

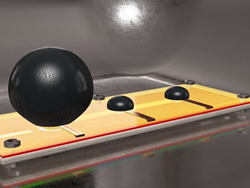

Jon Excell for The Engineer: Designed by a team at the Max Planck Institute for Intelligent Systems in Stuttgart, the new device is claimed to have considerable advantages over existing pneumatically-powered soft actuators as it doesn’t require a tether.

The device consists of a dielectric elastomer actuator (DEA): a membrane made of hyperelastic material like a latex balloon, with flexible (or ‘compliant’) electrodes attached to each side.

The stretching of the membrane is regulated by means of an electric field between the electrodes, as the electrodes attract each other and squeeze the membrane when voltage is applied. By attaching multiple such membranes, the place of deformation can be shifted controllably in the system. Air is displaced between two chambers.

The membrane material has two stable states. In other words, it can have two different volume configurations at a given pressure without the need to minimize the larger volume. Thanks to this bi-stable state, the researchers are able to move air between a more highly inflated chamber and a less inflated one. They do this by applying an electric current to the membrane of the smaller chamber which responds by stretching and sucking air out of the other bubble. Cont'd...

CU-Boulder Team's Octopus-Inspired 'Soft' Robot Wins International Challenge

Lightweight, mobile pneumatic hand excels at grasping "mystery objects"

18 months since the toolkit's release, soft robotics is flying

Gordon Hunt for SiliconRepublic: Pioneered in Ireland by the likes of Dr Dónal Holland, with a plethora of departments in Harvard University in the US involved, the Soft Robotics Toolkit has gone on to foster significant interest in an area exploding into the mainstream.

More than 76,000 people have engaged with the service since it was created, represented across 150 different countries, with the toolkit identified as having made one of the most significant contributions to the development of the nascent industry to date.

While robotics engineering used to focus much more attention on creating the rigid, hard-bodied prototypes like Bender from Futurama, for example, lately there has been a push towards soft, malleable structures that take their inspiration from nature. Cont'd...

Looking for a few good robots

By Adam Zewe for Harvard News: If you have a soft spot for robotics, this competition is right up your alley.

The 2016 Soft Robotics Competitions offer anyone with an interest in robotics the chance to design and build their own soft robot using the resources available in the open-source Soft Robotics Toolkit.

Now in its second year, the competition was developed by Conor Walsh, assistant professor of mechanical and biomedical engineering at the Harvard John A. Paulson School of Engineering and Applied Sciences, and Dónal Holland, visiting lecturer in engineering sciences, as a way to encourage individuals to take advantage of the resources provided in the Soft Robotics Toolkit.

The toolkit, which incorporates contributions from researchers from Harvard and other institutions, provides a set of intellectual tools that one can use to design and construct a robot using soft, flexible materials. It includes resources such as step-by-step instructions on building actuators and sensors, lists of suggested materials, and how-to fabrication videos.

The ultimate goal of the competition is to encourage others to find innovative applications for soft robotics technology and continue expanding interest in this relatively new field. Cont'd...

Rob Scharff's Soft Robotics 3D-printed hand responds to human grip

Dutch Design Week 2015: Delft University of Technology graduate Rob Scharff has created a soft robotic limb that can shake hands with people.

The hand was created as part of Scharff's Soft Robotics research project – which focuses on the ways robots can be integrated with more tactile materials, and so improve robot-human interactions. Cont'd...

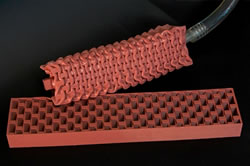

Soft Robotics Project Exo-Biote 3D Prints Living Movement

BY HANNAH ROSE MENDOZA for 3DPrint.com: Soft robotics is a relatively new field of research that aims to create flexible robots that are more easily adaptable to human interaction. Often, the forms of these creations and the mechanics of their movement are inspired by a close study of nature in an effort to ‘go organic’ with machines. 3D printing with flexible filament is one way in which this integration of robot and movement is taking on a flexible aspect.

For this particular installation, titled Exo-biote, the National Institute for Research in Computer and Control and the Department of Science and Visual Culture at the Imaginarium worked together, with support from Neuflize Bank, to create a robot organism that embodied the formal typologies and demonstrated the possibilities for movements in soft robots. After all, some of nature’s most amazing machines have nearly entirely soft bodies – think of the octopus, for example, able to lift, carry, walk, swim, shape change, camouflage itself, and fit through a tube no bigger than a quarter! Cont'd...

Announcing the 2015 Soft Robotics Competitions!

The 2015 Prize for Contributions in Soft Robotics rewards academic researchers for sharing their work and advancing the field. The competitions include $10,000 in prizes!

Records 31 to 42 of 42

Featured Product

MVTec MERLIC 5.8

With MERLIC 5.8, MVTec expands its easy-to-use machine vision software. The latest version improves process reliability beyond pure image processing, offering enhanced error handling and optimized configuration. This enables faster setup and stable deployment across diverse production environments. Explore MERLIC 5.8 now

Robotics and Automation - Featured Company

PNY

PNY Professional Solutions provides customers with powerful tools to manage heavy workloads. PNY offers NVIDIA Professional, Consumer GeForce RTX, and Data Center GPU Solutions, along with PNY Memory upgrades and Solid-State Drives. All PNY products are designed and built with system integrators in mind to provide advanced application performance, top productivity, and greater power efficiency.