A3 Releases Vision for a U.S. National Robotics Strategy

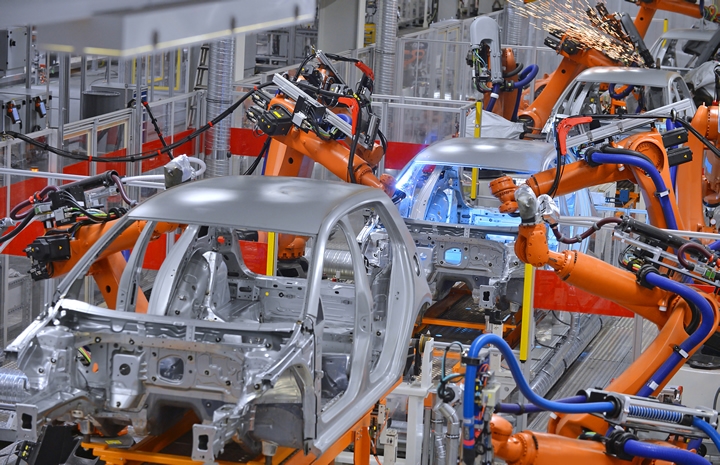

The Reshoring Revolution: Navigating New Policies For A Manufacturing Renaissance

NGen, Humber Polytechnic, and Festo Didactic Showcase Canadian Skills at Hannover Messe 2025

Everything You Need to Know About Buying and Selling Used Robot

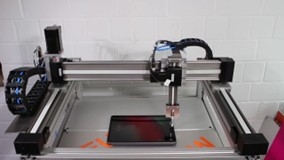

Low-Cost Robotics Elevate Industrial Inspection Processes

ProMat Q&A with Swisslog Americas

Robotic Software Market is Poised to Surpass USD 150 Billion by 2034

'Eyes, hands, brains and mobility' will define robotics beyond 2025

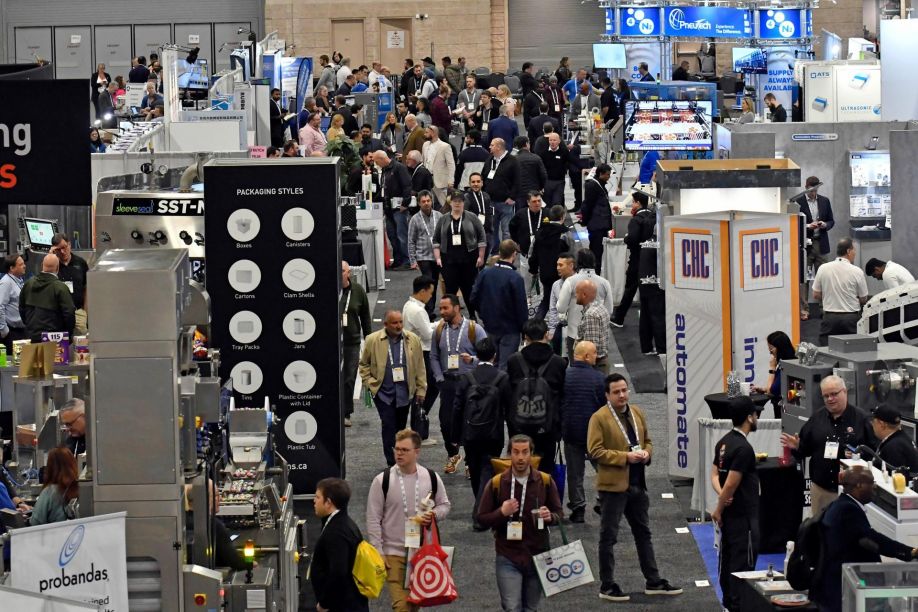

PACK EXPO Southeast 2025: The Future of Packaging & Processing Arrives in Atlanta

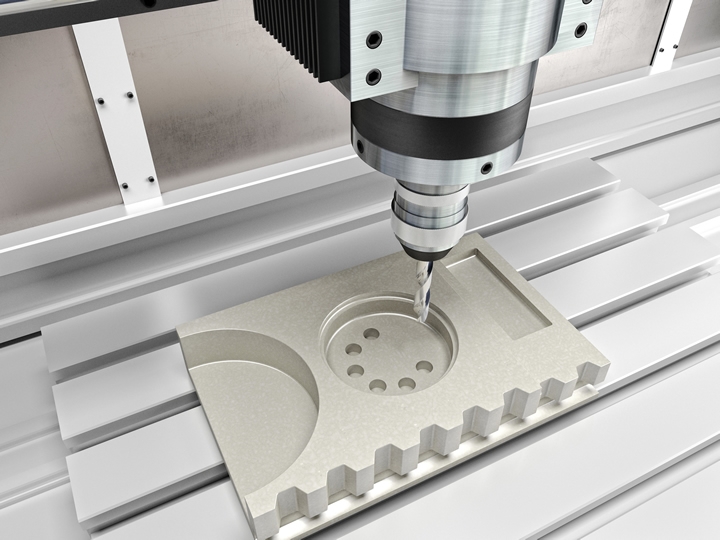

The Future of Machining: Key Trends and Innovations

Four questions to determine if AutoStore is right for your operation

Enterijer Mesicki and RoboDK Transform Serbian Furniture Manufacturing with FANUC Robots

Developing robotic solutions: partnering for success in micro-motion control

Maximum process reliability for the protein source of the future

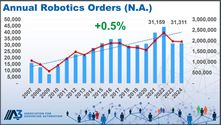

A3 Reports North American Robotics Market Holds Steady in 2024 Amid Sectoral Variability

Records 31 to 45 of 2113

First | Previous | Next | Last

Industrial Robotics - Featured Product

.jpg)