2025 Top Article - The Future of Machining: Key Trends and Innovations

AI and robotics are seen to deeply disturb specialized industry sectors, bringing beneficial pioneering modernizations in machining, industrial manufacturing and machine shops. Elitsa Krumova explores the future of machining in more depth on behalf of DELMIA.

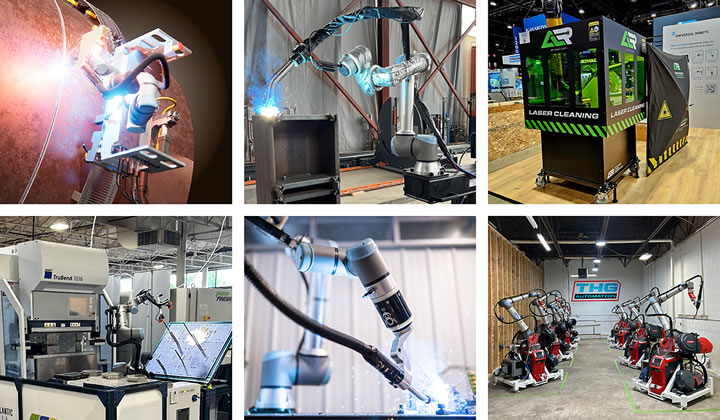

Universal Robots Expands 'Beyond the Welding Cart' at FABTECH 2024

Featuring new advanced welding solutions for multi-axis, coordinated welding. New cobot capabilities will also be showcased in extended reach and portability applications, and in tasks such as laser restoration, finishing, and press brake tending.

The Future of Metal Manufacturing for Robotics

Local manufacturers don't want to run 1-2 parts because it interrupts their workflow. They would much rather get an order for 1,000 pieces than have to stop, load material for your job, setup the machine, cut it, ship it etc.

Records 1 to 3 of 3

Featured Product

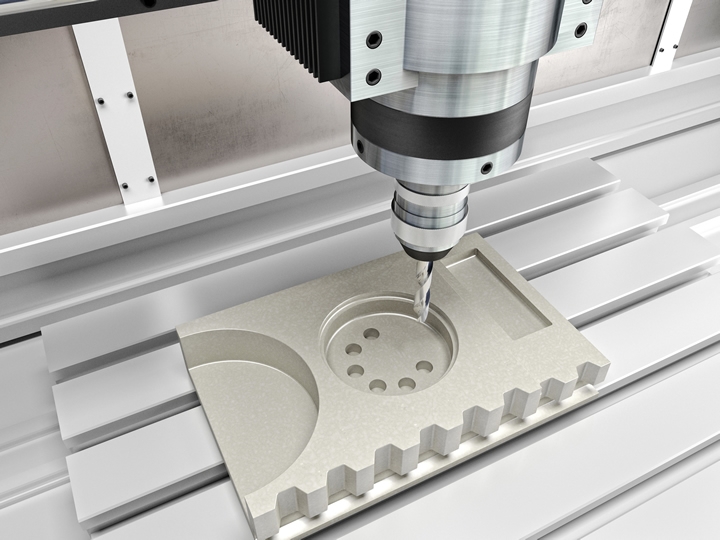

PI USA - Gantry Stages for Laser Machining and Additive Manufacturing

High performance gantry systems, from PI, are used in precision assembly, laser machining, and additive manufacturing. Complete with software and state-of-the-art EtherCat® motion controllers. Easy to program, easy synchronization with lasers and dispensers. Standard and custom, compact systems and large, granite-based units.

Robotics and Automation - Featured Company

Servo2Go.com Ltd.

Servo2Go.com is an Online E-Store Distributor of Automation & Motion Control Systems & Components including: Servo Motors & Drives, Stepper Motors & Drives, Automation & Motion Controllers, HMIs, Positioning Systems & Actuators, Gearboxes, Couplings, Brakes, Encoders, Tachometers and Linear Displacement Transducers. Servo2Go.com is an ISO9001:2015 Registered Company.