SCARA Robot Sorts Recyclables Using a Simple Conveyor Speed Feedback System

As Everest Labs was developing their system to be sold to recycling centers worldwide, they found that their robot needed speed feedback in order to track the recyclables on the conveyor, and therefore needed a simple way to install conveyor speed feedback on a gear motor.

Choosing the Right Encoder for Your Robot

Most robots use servo motors to move their joints, calling for rotary or angle encoders. As speeds increase, so do the control dynamics the motors require, sometimes making vibration mitigation just as important accuracy and resolution.

US Digital Automates Production Process Using Robot and In-House Engineering Talent

When US Digital released the E4T Miniature Optical Kit Encoder it needed to update manufacturing procedures to better handle the miniaturized encoder disks. The company decided to use automation and built the delta robot system above.

Industrial Robots: Encoders for Tool Center Point Accuracy

The use of secondary encoders on all of a robots axes, as well as the use of linear encoders for positioning the robot relative to the workpiece, enables a level of accuracy at the tool center point

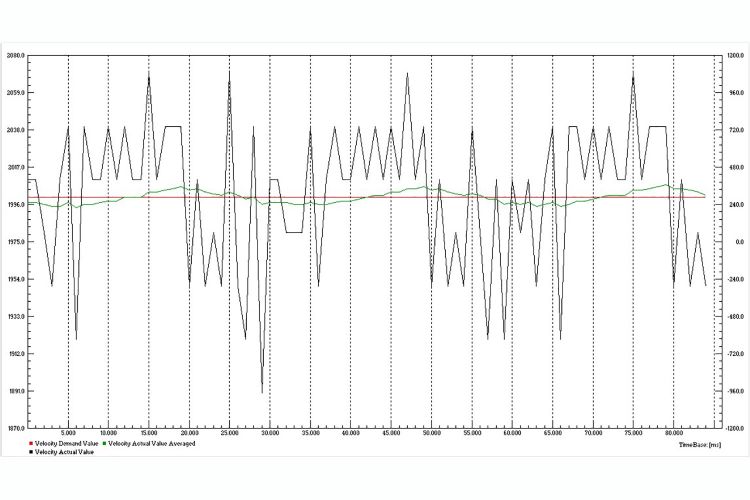

Encoder Selection: Speed Control

A general in depth analysis shows that the highest encoder resolutions are required for very precise speed control. The encoder resolution increases with the square of the demanded speed accuracy.

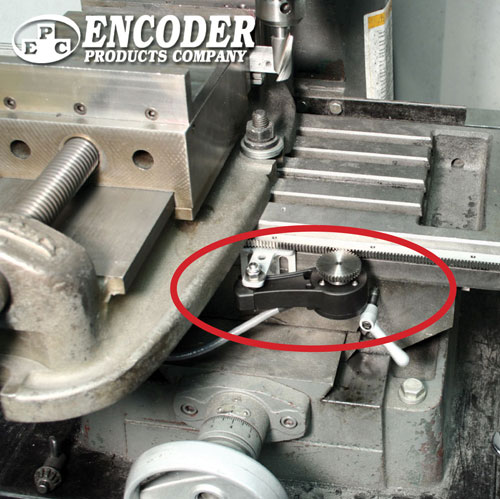

Tru-Trac Keeps Frankenstein Alive

This machine was assembled from various parts from other machines, so "Frankenstein" was really the only logical name for it.

What IS an Encoder?

Encoders use different types of technologies to create a signal, including: mechanical, magnetic, resistive and optical - optical being the most common.

Records 1 to 7 of 7

Featured Product

New incremental encoder IERF3 L from FAULHABER

FAULHABER is expanding its product range with the ultra-precise incremental encoder IERF3 L. Thanks to the optical measuring principle and state-of-the-art chip technology, the device offers the highest resolution, excellent repeatability, and outstanding signal quality. In typical applications, the positioning accuracy is 0.1° and the repeatability 0.007°. This makes the encoder the perfect solution for high-precision positioning applications in confined spaces.

Robotics and Automation - Featured Company

maxon group

maxon is a leading supplier of high-precision DC brush and brushless servo motors and drives. These motors range in size from 4 - 90 mm and are available up to 500 watts. We combine electric motors, gears and DC motor controls into high-precision, intelligent drive systems that can be custom-made to fit the specific needs of customer applications.

.jpg)