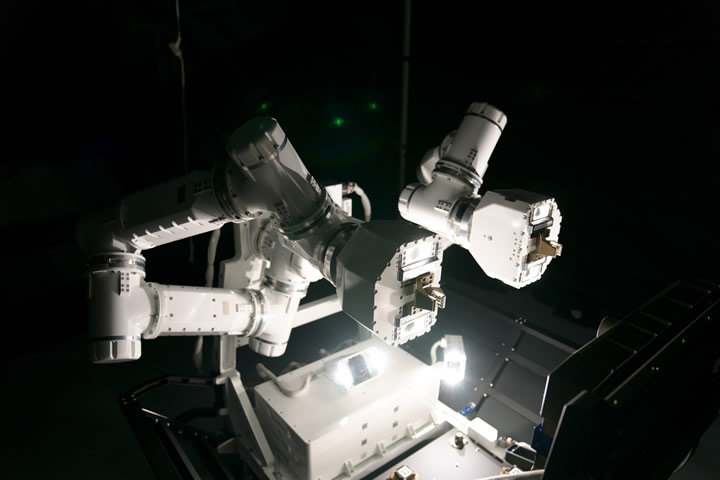

GITAI Autonomous Robotic Arm Set to Launch on Jan. 29 to International Space Station

During the demonstration, the S2 will be mounted external to the International Space Station (ISS) on the Nanoracks Bishop Airlock and perform on-orbit services, including maintenance, inspection, and life-extension operations for satellites.

5 Challenges a Motor Has to Overcome on Mars Home

Outer space is unforgiving. This is why precision drives embarking on a trip to other planets need to meet extremely high quality standards.

Robotics Leads the Way For Space Exploration

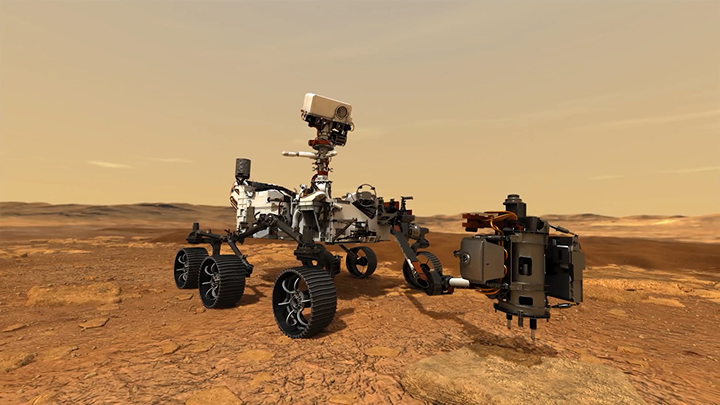

Motiv Space Systems made several contributions to the Mars 2020 Mission. The Perseverance Robotic Arm was the highest visibility subsystem development. This role required a close relationship with the JPL systems engineering team responsible for the sample and caching efforts.

ATI Develops Space-rate Force /Torque Sensor for Mars 2020 Rover

JPL needed an automated system for collecting and handling space material as well as moving it through the indexing process. Engineers developed the Adaptive Caching Assembly, an application that resembles a pick and place operation commonly found on a factory floor.

Brain Corp Raises $36 Million to Meet Growing Demand for Autonomous Robots

Brain Corp, an AI company creating transformative core technology in the robotics industry, today announced it has raised $36 million in Series D funding to help meet the growing demand for autonomous mobile robots (AMRs) now on the front lines of the COVID-19 health crisis.

Will Creating Robots for Space Travel Become More Necessary in the Near Future?

The good news is that space-based exploration, travel and research are all ramping up not just at renowned organizations like NASA, but also at privatized operations such as Space-X and Made In Space.

Pioneering the Next Era of Space Operations and Exploration Through On-Orbit Servicing, Assembly and Manufacturing

The ability to robotically service, assemble, and manipulate assets in space promises to enable entirely new capabilities for commercial and government missions and will become essential to our exploration of the universe.

Meet the Free-flying Camera on the ISS

Meet the new colleague for the crew of the International Space Station (ISS): an autonomous camera drone. The small sphere films the astronauts at work and this drone could potentially save about ten percent of their valuable working time.

DARPA taps Boeing for unmanned reusable spaceplane

Ross Wilkers for Washington Technology: Boeing has emerged as the winner of a DARPAcompetition to design and test an unmanned reusable spaceplane.

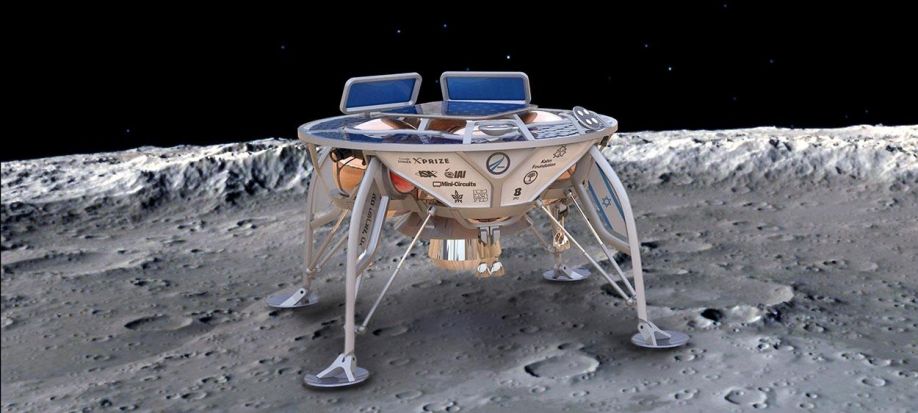

Another Race to the Moon-This Time by Robots

On September 13, 1959, the Soviet Union landed the first human-made object on the surface of the Moon. The United States landed the first human on July 20, 1969. Now, there is a race to land the first robot on the moon.

Records 1 to 10 of 10

Featured Product

ResinDek TRIGARD ESD ULTRA FOR HIGH-TRAFFIC ROBOTIC APPLICATIONS

To maximize the productivity of an autonomous mobile robot (AMR) or automatic guided vehicle (AGV) deployment, it's critical to create the optimal environment that allows the vehicles to perform at their peak. For that reason, Cornerstone Specialty Wood Products, LLC (www.resindek.com) created the TriGard ESD Ultra finish for its ResinDek engineered flooring panels. The TriGard ESD Ultra finish is ideal for high-traffic robotic applications characterized by highly repetitive movement patterns and defined travel paths.

Robotics and Automation - Featured Company

TM Robotics (Americas) Inc

TM Robotics, in partnership with Shibaura Machine, formerly known as Toshiba Machine until 1st April 2020, offers a comprehensive range of industrial robots ideally suited for high-precision assembly, machine loading/unloading and material-handling applications that can be dust proof, clean room, or IP65/67. The company's extensive product line starts with a Cartesian solution available in thousands of combinations from single actuators to four-axis solutions; six-axis solutions that can include precise vision-control; and a complete range of SCARAs from low cost to the industry-leading SCARA with 1200-mm reach that can carry up to 20 kgs. TM Robotics sells and services robots throughout Europe, the Middle East, India, Russia, and Africa, as well as North, Central, and South America, from headquarters in Hertfordshire, England and Elk Grove Village, IL, USA. For more information, visit www.tmrobotics.com or follow us on Twitter, LinkedIn and YouTube.