Automation and Humans: Will We Be Replaced?

RightHand Robotics Announces Strategic Investment from Rockwell Automation

Robotic Software Market is Poised to Surpass USD 150 Billion by 2034

'Eyes, hands, brains and mobility' will define robotics beyond 2025

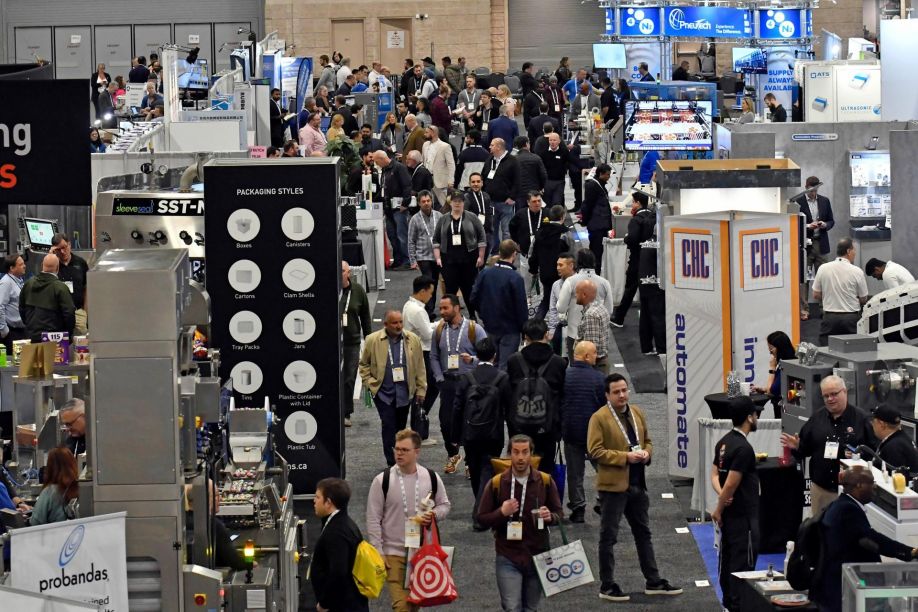

PACK EXPO Southeast 2025: The Future of Packaging & Processing Arrives in Atlanta

Mobile Robot Charging Station Market to Hit $38 Bn by 2031 at 15.9% CAGR | Persistence Market Research

Enterijer Mesicki and RoboDK Transform Serbian Furniture Manufacturing with FANUC Robots

Top 5 trends for the AIoT industry in 2025

Dürr equips first BYD plant in Europe with sustainable painting technology

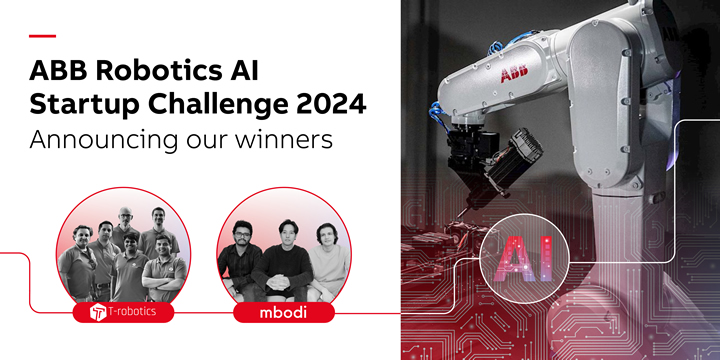

ABB Robotics names T-Robotics and Mbodi as AI Startup Challenge Winners

Mobile robot forecast downgraded as macro-economic factors continue to bite

The Battle of Price and Progress: Making AI Affordable for the Smaller Businesses

Can cobots attract more young talent to welding?

Revolutionizing Warehouse Floors: How AGVs & AMRs are Driving Safety in Modern Manufacturing

Choosing Zero Trust Network Access Over Virtual Private Networks is a C-Suite Decision

Records 16 to 30 of 435

First | Previous | Next | Last

Factory Automation - Featured Product

.jpg)

.jpg)

.jpg)

.jpg)