Flexible Conveyor Manufacturer Glide-Line Overcomes Space, Size, & Product Handling Constraints for Aerospace Industry Integrator

Their client needed a conveying solution integrated into their current facility. The over-sized product, an aircraft wing support beam, needed to be handled incredibly carefully to avoid product damage.

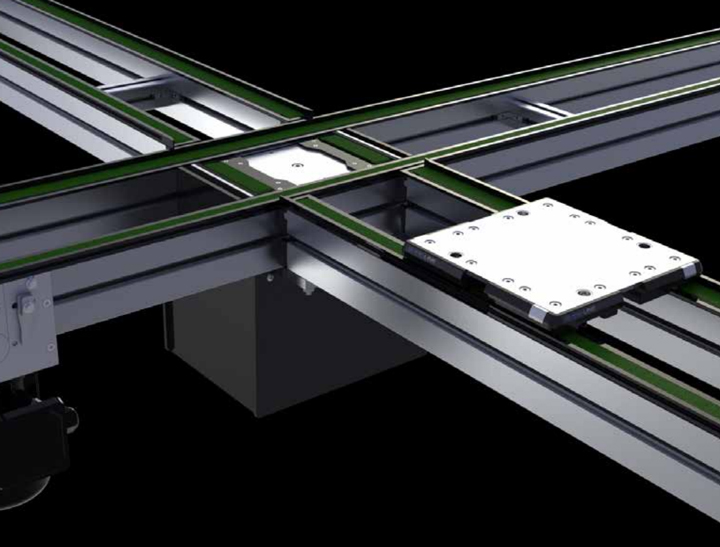

Five Methods to Transfer Products with Conveyors

There are many reasons to transfer a product from one conveyor system to another. Whether you're moving a product to another line for further operations, into a repair area, or into a rejection location, different transfer methods might be in order.

Discussing West Pack with Dorner Conveyors

Conveyors, although often a last thought, can play a pivotal role in the optimization of a manufacturing facility. A processing line can only go as fast as the slowest piece of equipment.

Booth #5014

Everything You Want to Know About Alpine Conveyors

The Alpine Conveyor is a compact spiral configuration commonly used as an accumulation or elevating buffer zone between machines or as a process step for cooling or drying. It can also be used for line balancing or product changeover purposes.

Everything You Want to Know About Wedge Conveyors

Wedge Conveyors are used to take products from production floor level to a higher level or vice versa. Products are wedged between opposing conveyors aligned vertically or horizontally and are moved swiftly but securely.

Can You Complete Your Project Without A Conveyor? The Pros and Cons

Lets explore some common misconceptions about conveyors, as well as some pros and cons of conveyor alternatives.

Trends in Conveyor Systems and Technology

Conveyors today are built to your specifications to improve efficiency and output of your production line. Theres no reason to settle for a conveyor thats being shoe-horned into your application

Glide-Line Conveyor Case Study: Automating in-context Conveyor Configuration With Solidworks

We needed a powerful configuration platform so customers would have access to complete assemblies, could easily put systems together using automated snaps, and manage operational states

Farason Corporation Chooses Dorner Conveyors to Integrate with its Robotic Machine to Successfully Assemble Coin Proof Sets

Placing coins into a coin presentation case insert sounds like an easy thing to do, right? But when the application calls for placing several thousand coins in exact places on moving inserts every day, the task becomes much more demanding.

Records 16 to 24 of 24

Featured Product

Elmo Motion Control - The Platinum Line, a new era in servo control

Significantly enhanced servo performance, higher EtherCAT networking precision, richer servo operation capabilities, more feedback options, and certified smart Functional Safety. Elmo's industry-leading Platinum line of servo drives provides faster and more enhanced servo performance with wider bandwidth, higher resolutions, and advanced control for better results. Platinum drives offer precise EtherCAT networking, faster cycling, high synchronization, negligible jitters, and near-zero latency. They are fully synchronized to the servo loops and feature-rich feedback support, up to three feedbacks simultaneously (with two absolute encoders working simultaneously). The Platinum Line includes one of the world's smallest Functional Safety, and FSoE-certified servo drives with unique SIL capabilities.

Robotics and Automation - Featured Company

PDS / Precision Drive Systems

Over 40,000 Spindles Repaired or Rebuilt Since 1996. PDS is a global leader in spindle repairs and retrofits for precision metal and robotics applications. With over 40,000 spindles repaired to better than-new-condition. PDS also offers new spindles, CNC accessories, and Industry 4.0 spindle monitoring. With offices in Bessemer City, NC (near Charlotte) and Herford, Germany PDS backs superb craftsmanship with a standard 12 month warranty on repaired spindles and an optional, industry-leading 24 month PrecisionCare warranty.