Conveyor Application Challenges to Consider: Scalability, Expansion, Automation, and Integration

Designing a conveyor system that overcomes common challenges like scalability, expansion, automation, and integration is possible with the right manufacturer. Here are 5 ways you can solve your application challenges with conveyor design.

Methods for Empty Carton Induction in Pick Modules

The method you choose for delivering empty cartons can significantly impact productivity and operational efficiency. Here, we explore three common methods for empty carton induction to Pick Modules, highlighting the benefits of using an overhead conveyor system.

How Parvalux Is Helping to Develop the Next Generation of Conveyor Systems

Conveyor systems are central to most warehouse operations, and without regular maintenance, downtime can prevent a warehouse from functioning which obviously has a large financial impact.

Which Product Transfer is Best - Pros and Cons of 6 Transfer Methods

The transfer method can vary widely depending on the product and process being performed. We'll review the five main transfer options available, discuss their pros and cons, and show which application they are best suited for.

Enhancing Production Efficiency Through Intelligent Transfer Systems

A smooth production process is critical for a company's success. The constantly growing demands of the market and increasing cost pressure require innovative solutions to optimize production. This is where transfer systems come into play.

5 Advantages of Buying vs Making an Embedded Conveyor for OEM Applications

By outsourcing this essential component of their projects, businesses can gain a competitive edge, save valuable time, reduce costs, and benefit from the expertise of conveyor system manufacturers.

Case Study: Glide-Line's Zero Contact Zoned Conveyor For Integrator, Mid-South Industrial Automation

Mid-South Automation's team was challenged to find a cost-effective way to make a 34 station modular system, making each module (or section) self-powered.

Talking AUTOMATE 2023 with Dorner

We will be showcasing all four of our pallet system conveyors: the FlexMove, ERT150, ERT250, and Precision Move conveyors. Each conveyor is designed to interface with robotics and operators, as well as move product through machinery during the manufacturing process.

Exploring the Design and Benefits of Modular Conveyor Systems

In the following white paper, we explore four conveyor options that fit our modular automation system, enabling you to design a full integrated conveyor system for your application.

Optimize Space with Conveyor Elevations and Line Egress Solutions

Modern manufacturing requires facilities to maximize efficiency and ensure product quality. However, space limitations can impede these goals. Integrating elevations and line egress solutions will grant your facility the flexibility it needs to succeed.

Robot-Ready Conveying Optimizes Pick-and-Place

From a machine builder's point of view, robots can solve many processing and packaging line problems, but the chosen material handling systems supplying the line can reduce the robot's performance.

Supplychainbrain: Out With Conveyors, in With Autonomous Mobile Robots

You can't totally count conveyors out, because they'll always have a place. But the truth is, robots are here, and AMRs are changing warehouse operations. While conveyors are effective, their capabilities are also limited.

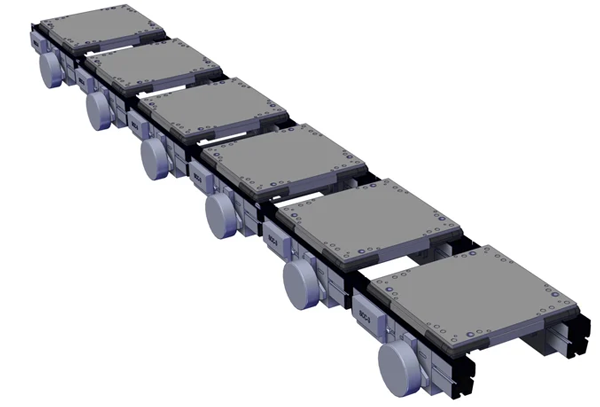

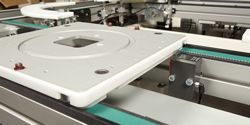

Edge Roller Technology (ERT®250) Conveyor

The system uses rollers to move pallets smoothly, without friction (a byproduct often seen in belt-driven platforms). The conveyor's open design eliminates concerns of small parts or screws dropping into rollers and causing conveyor damage or jamming.

Staying Competitive with Automation

Automation is making conveyors a more integral component because of the contributions they're making to the overall efficiency and productivity of today's processing and packaging lines.

Autonomous Mobile Robot (AMR) Conveyors for Small Loads & Applications

When your clients are working with you to integrate lightweight autonomous mobile robots (AMRs), they're looking for the biggest bang for their buck.

Records 1 to 15 of 24

Featured Product

PI USA - Gantry Stages for Laser Machining and Additive Manufacturing

High performance gantry systems, from PI, are used in precision assembly, laser machining, and additive manufacturing. Complete with software and state-of-the-art EtherCat® motion controllers. Easy to program, easy synchronization with lasers and dispensers. Standard and custom, compact systems and large, granite-based units.

Robotics and Automation - Featured Company

US Digital

US Digital's breadth of quality motion control products offers a range of sizes and CPRs, delivering the position accuracy you demand. With over 1 million off-the-shelf configurations, including custom designs and manufacturing, we put ultimate precision into your application. US Digital has delivered quality in motion since 1980. Located in Vancouver, WA, the vertically integrated facility and the stellar service team offer shorter lead times, with same-day fulfillment on most orders.