How High-Precision Reducers Drive the Development of Intelligent Manufacturing Technology

Humanoids - Safety Standards for the Next Wave of Robots

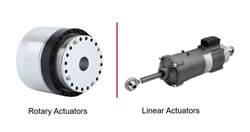

Linear Actuators vs Rotary Actuators: The Core Choice for Humanoid Robot Joints

How the Best Infrared Thermal Modules Enhance Machine Vision for OEMs

How to Improve Warehouse Picking Speed with Automation

Rugged electric actuators provide reliable steering for extensible, self-driving platform

Building a Better RFP: A Practical Guide to Choosing the Right Automation Partner

PILLARS OF TOMORROW - A hopeful vision of Government, Technology, and Human Dignity in harmony

Flexibility vs. Predictability in Mobile Automation: What Facilities Should Really Be Considering

What Warehouses Really Need to Compete in the Age of AI

Kassow Robots' Edge Edition 7-axis Collaborative Robot Arm

UR20 Cobot Enables New Palletizing Opportunity at Bob's Red Mill

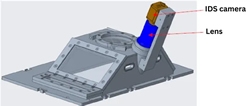

High-precision process monitoring and error detection in additive manufacturing

Smart Supply Chain Strategies for Cold Storage: Solving Challenges with Scalable Automation

The SPT-1500UL from SEER Robotics

Records 31 to 45 of 2067

First | Previous | Next | Last

Featured Product

Palladyne IQ - Unlocking new frontiers for robotic performance.

Robotics and Automation - Featured Company