CASE STUDY STT SYSTEMS and STEMMER IMAGING: AUTOMOTIVE BOLT INSPECTION SYSTEM WITH GOCATOR SMART 3D LASER PROFILERS

How U.S. Manufacturing VPs Can Close the Execution Gap — The New Playbook for Operational Excellence

The Right 3D Vision Scanner for Robotic Programming: Laser Profilers vs Structured Light Scanners in Industrial Automation

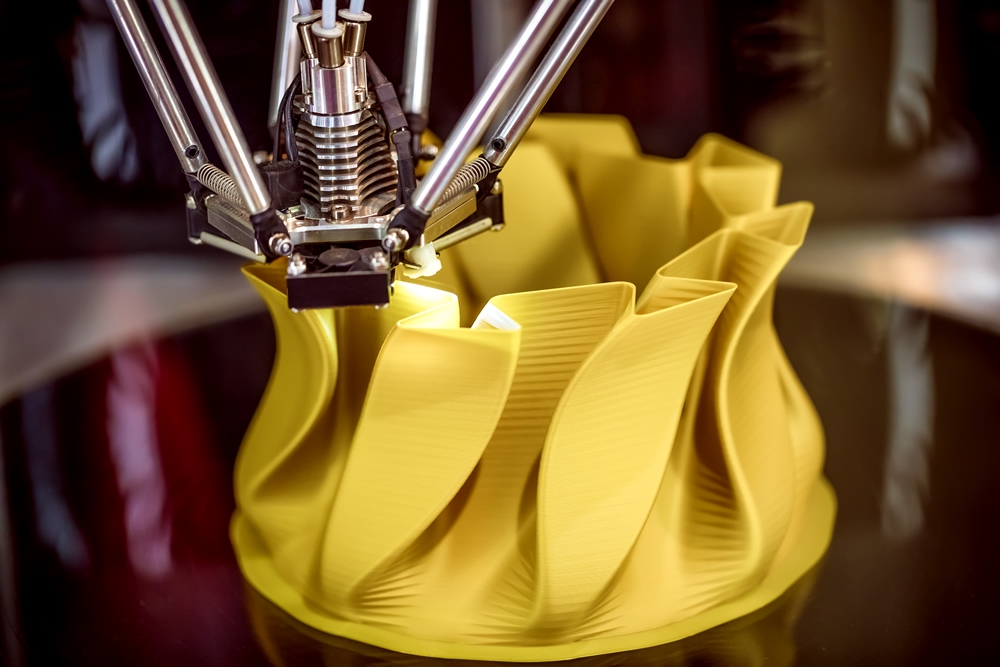

What are the motion control requirements for additive manufacturing machines?

What is Agentic AI and is it here to stay?

Automation Solutions Mergers & Acquisitions Update

How LAPP Rebuilt Its Inventory Process with Autonomous Drones

Sonair's ADAR 3D Ultrasonic Sensor

Optimizing Wheel Drives for AGVs and AMRs: What OEMs Need to Know About Motion Control

Moving Construction from Digital Design to Physical Reality

Fully Autonomous Vehicles for Repetitive Hauling in Manufacturing

Designing Human-Centric Automation: The Next Evolution of Robotics in the Supply Chain

Decorating plastics with robotic precision

Precision Measurement Technology Combined With Autonomous Robots

Deep Dive into integration challenges of ONVIF-compliant GigE cameras and how ONVIF enhances interoperability

Records 16 to 30 of 2067

First | Previous | Next | Last

Featured Product

Strain Wave Gearheads by maxon - Highly precise, compact, and efficient.

Robotics and Automation - Featured Company