User-Friendly Palletizing System Powered by D:PLOY Up and Running Within One Day at Dutch Distillery

Schrobbelèr B.V., producer of an iconic Dutch herbal liquor since 1973, was ready to automate its palletizing tasks but needed an approach that could seamlessly integrate into its operations without disrupting the company's traditional craftmanship.

Are Labeling and Palletizing Robots the Secret Weapon Manufacturers Need?

Robots are not magic fixes to all manufacturing industry obstacles, but they can allow users to overcome many challenges when implemented thoughtfully.

CMES Robotics Introduces Innovative Mixed Case Palletizing Solutions

This collaboration aims to address the growing demand for flexible and efficient palletizing solutions in industries such as e-commerce, logistics, food and beverage, manufacturing, and more.

New ABB SWIFTI industrial cobot delivers class-leading speed, accuracy and safety

SWIFTI™ CRB 1300 industrial collaborative robot is six times faster and five times more precise than other robots in its class. Combination of high payload capability - up to 11kg - and speed improves production efficiency by up to 44%.

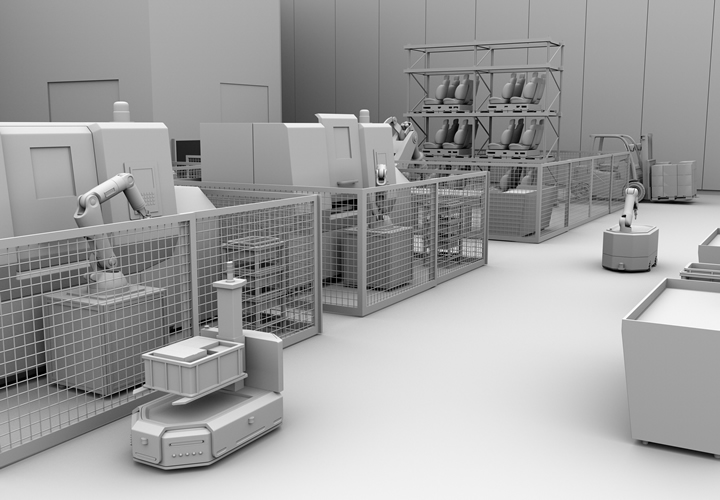

KPI INTEGRATED SOLUTIONS OPENS FIRST FULL-SCALE DEMONSTRATION SITE IN NORTH AMERICA FOR NEW GEEK+ FOUR-WAY SHUTTLE SOLUTION

As part of a KPI-designed operation that increases storage capacity, boosts throughput, and builds flexibility, the Geek+ Four-way Shuttle supports multiple picking and storage strategies for pallets, containers, and individual units.

Low-maintenance Palletizer Magnet Saves Robot and Manpower

The palletizing magnet design recently modified by Goudsmit Magnetics consists of modules that vary in design. The low-maintenance magnet is suitable for palletizing and depalletizing cans, aerosols, canisters and glass jars with steel lids.

LOW-MAINTENANCE PALLETISER MAGNET SAVES ROBOT AND MANPOWER

The modular construction offers users, such as integrators, packaging companies, food producers or pharmaceutical companies, a number of choices that save on an extra robot and manpower.

Picked Up and Put Off

Pallets loaded with industrial yarn spools are picked up from the floor of a predefined storage place and transported to the creel location. There, the gripper positions itself vertically above the pallet.

Automated Palletizing of Sweet Tea and Juice From a Cold Room

While palletizing cartons is a regular automation application, doing so from a cold room that is regularly hosed with water to stay clean is a specific challenge. Motion Controls Robotics overcame these by using vacuum technology from Piab supplied by Neff Grp Dist.

Conventional vs. Robotic Palletizing

Rather than getting immersed in ambiguous statistics and marketing buzzwords like flexible or fixed automation, this paper looks at the specific applications that favor each technology to chart the future of palletizing automation.

Asyfeed Pocket Module Feeding System Handles Swiss Watches' Most Delicate Parts

The feeding system can handle parts smaller than 0.1 mm and up to 10 mm in size.

Cartoners, Case Packers, and Palletizers for Track and Trace Serialization of Pharmaceutical Packaging Lines

By integrating OEM serialization systems with packaging machinery, pharmaceutical manufacturers can secure their supply line from counterfeiting and meet current and future pedigree requirements.

Largest Ever Pro Mach Presence at Expo Pack Mexico - Two Full Islands of Packaging Machines and Solutions

Fourteen original equipment manufacturing brands will showcase primary packaging, end-of-line packaging, flexible packaging, bottling & capping, and identification and tracking under the Pro Mach banner at the Centro Banamex Convention Center, Mexico City, June 16-19.

Pro Mach Expands Sales and Support for Latin American Customers with a New Business and Facility in Mexico

The new Pro Mach Mexico Shared Services business will open a sales, technical support, equipment, and parts stocking facility in Monterrey, Mexico, this summer. See Pro Mach and 14 of its more than 20 brands at Expo Pack Mexico June 16-19.

Robotic End of Press Palletizing Solution

The main objective was to install a flexible robotic palletizing solution that can handle heavy stacks up to 130 lbs at the end of the printing line, and handle the highest throughput of 8 stacks per minute on one particular product.

Records 1 to 15 of 15

Featured Product

ElectroCraft's Motion Control for Mobile Robots

ElectroCraft is showcasing its award-winning mobile robot technology including their powerful and compact wheel drives, high-torque-density brushless DC motors, precision linear actuators as well as servo motor drive technology at a variety of conferences and tradeshows including the Boston Robotics Summit. Robotics Summit is the premier symposium for the sharing of ideas, technology, and market developments for robotic technologies across industries. Beyond a showcase and pitch of product, ElectroCraft is eager to participate in the collaborative discussion of challenges and opportunities that will shape the near and long-term robotic marketplace.

Robotics and Automation - Featured Company

Oriental Motor Corp. USA

Since our founding in Japan in 1885, Oriental Motor globally has been providing the optimal motion systems as part of our total service, to meet the widest market demands. We manufacture and sell AC Motors, Stepper and Servo Motors, Linear and Rotary actuators, Network Solutions, Accessories and Thermal Management solutions. Oriental Motor's sales and service network is international, with offices throughout North America, Europe and Asia.